Mar . 05, 2025 02:38 Back to list

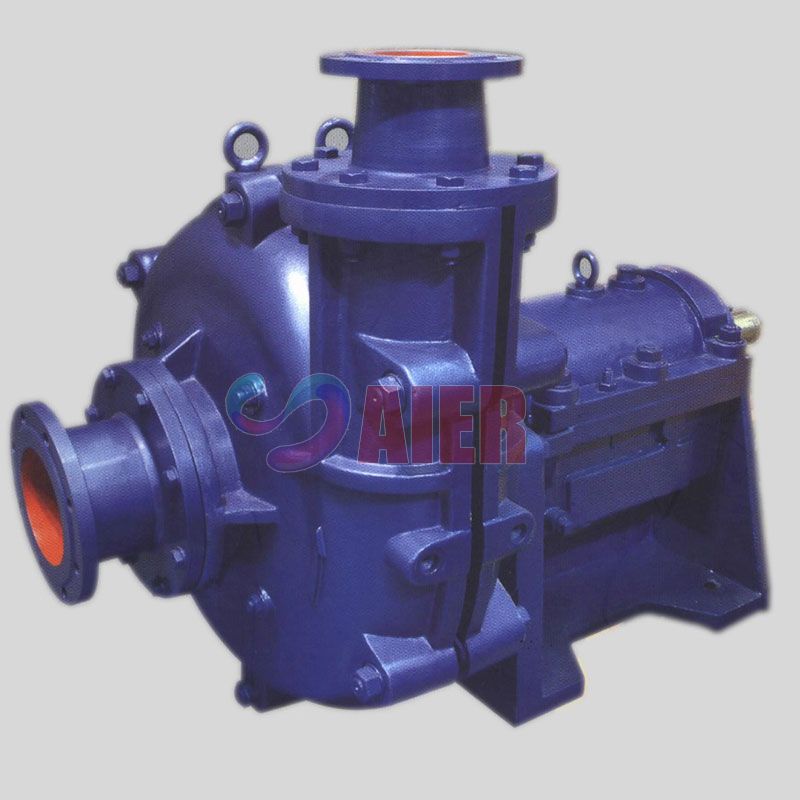

wholesale slurry pump rubber impeller

The landscape of industrial equipment is evolving, yet the importance of efficient and reliable components remains constant. Among these components, the rubber impeller used in slurry pumps stands out due to its critical role in various industries, including mining and wastewater management. A well-designed rubber impeller not only enhances the efficiency of slurry pumps but also ensures their longevity, making them an invaluable asset for many operations.

From an expert vantage point, the integration of cutting-edge computational technologies in designing these impellers enhances their functionality. Computational fluid dynamics (CFD) is now an integral part of the design and testing phase, ensuring that each impeller achieves its optimal geometry and material composition. Such precision engineering allows businesses to leverage the best technology has to offer, ensuring their operations are environmentally sustainable, cost-effective, and efficient. The authority of manufacturers specializing in rubber impellers is crucial. Industry leaders uphold high standards for manufacturing processes, ensuring each product meets strict quality controls. Certifications and endorsements from recognized industrial bodies further validate their credibility in the field, offering assurance to clients about product reliability and durability. Trust in products like china rubber impellers of slurry pumps is established through demonstrated commitment to quality and performance. Manufacturers often provide comprehensive warranties and exceptional after-sales support, reflecting confidence in their products' performance across various conditions and applications. Trust is further bolstered when these companies actively engage in partnerships with their clients, providing tailored solutions that meet specific industrial needs. For facilities seeking to enhance their operational efficiency, investing in high-quality rubber impellers for slurry pumps presents both short-term and long-term benefits. The combination of reduced maintenance, increased pump efficiency, and decreased operational costs offers a compelling case for their adoption. In conclusion, the role of the rubber impeller in slurry pumps cannot be overstated. Its design, material choice, and the engineering process are integral to achieving superior performance in demanding environments. Companies prioritizing quality and reliability must consider upgrading to these components. By doing so, they position themselves for success in an increasingly competitive global market, ensuring operational excellence and sustained profitability.

From an expert vantage point, the integration of cutting-edge computational technologies in designing these impellers enhances their functionality. Computational fluid dynamics (CFD) is now an integral part of the design and testing phase, ensuring that each impeller achieves its optimal geometry and material composition. Such precision engineering allows businesses to leverage the best technology has to offer, ensuring their operations are environmentally sustainable, cost-effective, and efficient. The authority of manufacturers specializing in rubber impellers is crucial. Industry leaders uphold high standards for manufacturing processes, ensuring each product meets strict quality controls. Certifications and endorsements from recognized industrial bodies further validate their credibility in the field, offering assurance to clients about product reliability and durability. Trust in products like china rubber impellers of slurry pumps is established through demonstrated commitment to quality and performance. Manufacturers often provide comprehensive warranties and exceptional after-sales support, reflecting confidence in their products' performance across various conditions and applications. Trust is further bolstered when these companies actively engage in partnerships with their clients, providing tailored solutions that meet specific industrial needs. For facilities seeking to enhance their operational efficiency, investing in high-quality rubber impellers for slurry pumps presents both short-term and long-term benefits. The combination of reduced maintenance, increased pump efficiency, and decreased operational costs offers a compelling case for their adoption. In conclusion, the role of the rubber impeller in slurry pumps cannot be overstated. Its design, material choice, and the engineering process are integral to achieving superior performance in demanding environments. Companies prioritizing quality and reliability must consider upgrading to these components. By doing so, they position themselves for success in an increasingly competitive global market, ensuring operational excellence and sustained profitability.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025