Aug . 05, 2024 12:41 Back to list

Top Recommendations for High-Performance Submersible Slurry Pumps for Various Applications

Best Submersible Slurry Pumps A Comprehensive Guide

When it comes to managing challenging fluid applications, such as transporting slurry— a mixture of solids and liquids— submersible slurry pumps are invaluable tools in industries like construction, mining, and wastewater management. These specialized pumps are designed to operate submerged in the fluid they are pumping, making them ideal for applications where traditional pumps would struggle. In this article, we will explore the features, benefits, and top considerations when selecting the best submersible slurry pumps for your needs.

Understanding Submersible Slurry Pumps

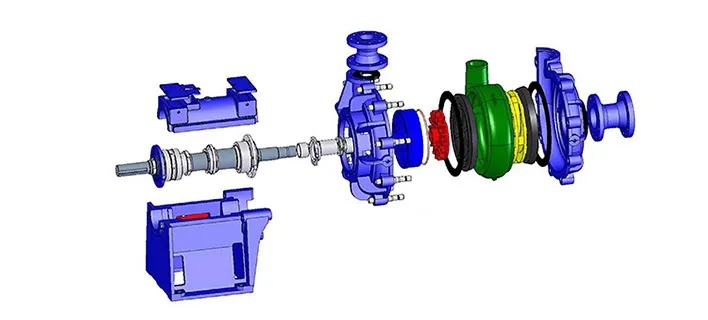

Submersible slurry pumps are engineered to handle abrasive materials, such as soil, rocks, or other solid particulates mixed with water. Unlike standard pumps, which are typically installed above the fluid source, submersible pumps are submerged directly in the slurry, allowing for efficient liquid transfer without the need for priming. These pumps utilize a hermetically sealed motor that prevents water or slurry from entering the motor housing, providing durability and reliable operation in harsh environments.

Key Features to Look For

1. Material Construction Given their duty in abrasive environments, the materials used in the construction of submersible slurry pumps are crucial. Pumps made from high-chrome alloys, stainless steel, or other durable materials can withstand wear and extend the pump's service life.

2. Impeller Design The design of the impeller significantly affects a pump's performance. High-efficiency, agitator-type impellers are commonly found in high-quality slurry pumps, allowing for the effective movement of solids while reducing the risk of clogging.

3. Flow Rate and Head Depending on the specific application, the required flow rate and pumping head (the height to which the pump can raise a fluid) vary. It’s essential to match these specifications to the operational demands of your project.

4. Power and Efficiency Assessing the power requirements of the pump is crucial for operational efficiency and cost-effectiveness. Electric motors with high-efficiency ratings can significantly reduce energy costs over time.

5. Ease of Maintenance Submersible pumps should have features that facilitate easy maintenance, such as accessible greasing points, removable wear parts, and a design that allows for straightforward inspection and repairs.

Benefits of Using Submersible Slurry Pumps

Submersible slurry pumps offer numerous advantages

best submersible slurry pump

- Reduced Footprint Because they operate underwater, submersible pumps require less installation space and eliminate issues related to priming

.- Versatility These pumps can handle various slurry types, making them suitable for multiple applications, from mining to industrial wastewater management.

- Increased Efficiency Operating submerged helps to reduce cavitation and air entrapment issues, enhancing overall pump efficiency.

- Safety and Environmental Protection The hermetically sealed design minimizes the risk of spills and leaks, protecting both workers and the environment.

Top Brands and Models

When selecting the best submersible slurry pump, it's important to consider reputable brands known for quality and reliability. Some notable brands include

- Sulzer Renowned for their advanced pump technology and robust designs, Sulzer offers various submersible slurry pumps suitable for different applications.

- Goulds Water Technology Known for its durability and efficiency, their slurry pumps are designed for challenging applications and come equipped with innovative features.

- Flygt (Xylem) Flygt pumps are famous for their performance in wastewater and industrial applications, with a strong focus on energy efficiency and reliability.

- Grundfos Their submersible pumps stand out for intelligent control technology and rugged construction, catering to a wide range of slurry pumping needs.

Conclusion

Choosing the best submersible slurry pump involves careful consideration of factors such as construction materials, impeller design, flow rate, and ease of maintenance. By investing in a high-quality pump from a reputable brand, businesses can optimize their operations, reduce downtime, and enhance overall productivity in slurry management tasks. Whether in mining, construction, or other industrial sectors, the right submersible slurry pump is a critical component for success.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025