Dec . 20, 2024 09:57 Back to list

Slurry Pump Solutions for Efficient Vapor Blasting Operations in Manufacturing Facilities

The Role of Slurry Pumps in Vapor Blasting Factories

Vapor blasting, also known as wet blasting or liquid media blasting, has gained significant popularity across various industries due to its ability to provide a superior finish compared to traditional dry blasting methods. At the heart of this process lies the slurry pump, a vital component that facilitates the efficient mixing and transportation of the abrasive slurry used in vapor blasting operations.

What is Vapor Blasting?

Vapor blasting is a wet blasting technique that utilizes a mix of water, air, and abrasive media to achieve a cleaner surface finish on various materials, including metal, fiberglass, and plastic. This method not only reduces dust and airborne particles during the blasting process but also minimizes the risk of damage to the substrate. The slurry pump plays a critical role in delivering the proper mixture of water and abrasive material to the blast nozzle, ensuring uniformity and consistency in the blasting process.

The Importance of Slurry Pumps

Slurry pumps are specifically designed to handle the challenging conditions of conveying abrasive mixtures. In vapor blasting factories, the pumps need to manage both the abrasive materials and liquid simultaneously. The effectiveness of a slurry pump can significantly influence the quality of the final finish, operational efficiency, and maintenance costs.

1. Material Handling Slurry pumps are constructed from durable materials that resist wear and corrosion, enabling them to handle abrasive materials such as glass beads, aluminum oxide, and garnet. Using the right slurry pump ensures that the abrasive media flows smoothly without clogging or damaging the pump itself.

2. Efficiency and Consistency The success of vapor blasting hinges on the precise mixture of water and abrasive. A high-quality slurry pump maintains a consistent flow rate and pressure, which is crucial for achieving the desired blasting results. Consistency in the application minimizes the risk of uneven surfaces and other defects, leading to higher quality output.

3. Versatility Slurry pumps can be adjusted to accommodate different types of abrasives and water ratios, providing flexibility for various blasting applications. Whether it’s delicate components requiring a gentle touch or heavy surfaces that can withstand more aggressive blasting, suitable slurry pumps can optimize the process.

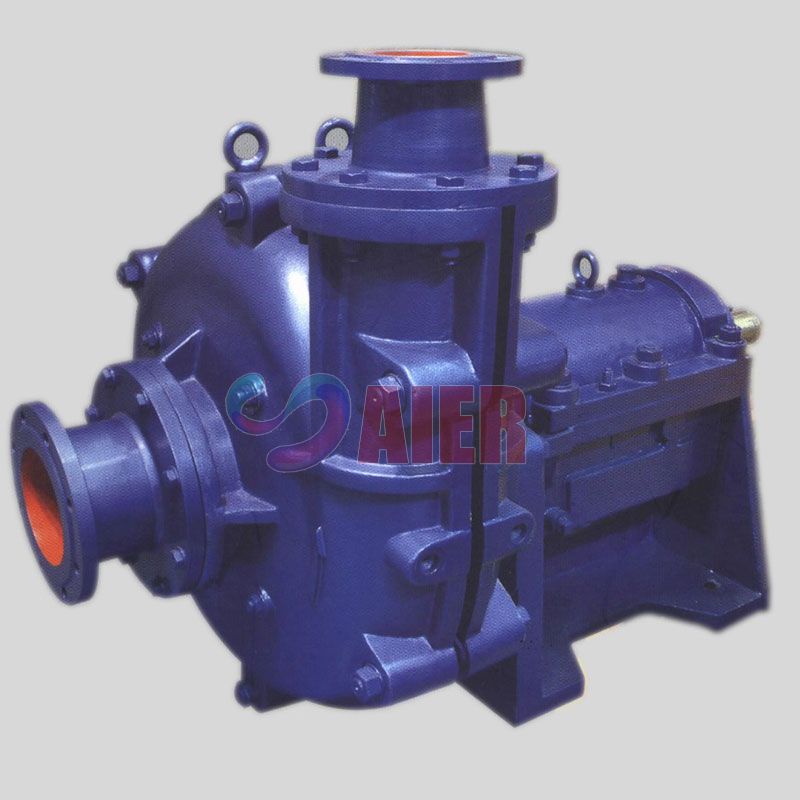

slurry pump for vapor blasting factory

Key Features to Consider in Slurry Pumps

When selecting a slurry pump for a vapor blasting factory, several factors must be taken into account

- Flow Rate and Pressure The pump should be capable of delivering the required flow rate and pressure to ensure optimal blasting performance. Understanding the specific needs of the operations helps in selecting the right model.

- Construction Material Look for pumps made of corrosion-resistant materials. The combination of abrasives and water can cause significant wear, so robust construction can prolong the life of the pump.

- Ease of Maintenance Regular maintenance is essential for optimal performance. Pumps that are easy to disassemble and clean can significantly reduce downtime in a production environment.

- Energy Efficiency With sustainability becoming increasingly important in manufacturing, choosing energy-efficient pumps can lead to cost savings over time while reducing the factory's overall environmental impact.

Conclusion

In summary, slurry pumps are indispensable in vapor blasting factories, where they ensure the efficient delivery of the abrasive slurry essential for achieving high-quality finishes. Their ability to handle abrasive materials, maintain consistent flow, and adapt to various applications makes them a key component in modern blasting operations. As industries continue to emphasize quality and efficiency, investing in reliable slurry pumping solutions will remain a priority for those looking to excel in the vapor blasting market.

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025

-

Heavy Duty Submersible Pumps Robust & Reliable Solutions

NewsJun.09,2025