Aug . 12, 2024 18:16 Back to list

Comprehensive Guide to Warman Slurry Pump Components and Their Functions in Industrial Applications

Understanding Warman Slurry Pump Parts

Warman slurry pumps are renowned for their robust design and durability, specifically engineered to handle abrasive and corrosive slurries across various industries, including mining, mineral processing, and wastewater management. The effectiveness of a Warman slurry pump largely depends on the quality and performance of its individual parts. Understanding these components is crucial for maintenance, operation, and ensuring the longevity of the pump.

Key Components of Warman Slurry Pumps

1. Pump Housing The pump housing, or casing, is the outer shell that encases the internal components of the pump. Typically made from high-chrome iron or rubber, it is designed to withstand high pressures and protect against wear and corrosion from the slurries being pumped.

2. Impeller The impeller is a rotating component that transfers kinetic energy to the slurry. Warman slurry pumps often feature impellers made from high-quality materials designed specifically for abrasive applications. The impeller geometry plays a crucial role in determining the efficiency and performance of the pump, affecting flow rate and head pressure.

3. Volute The volute is the part of the pump that converts the kinetic energy generated by the impeller into pressure energy. Its design is crucial in managing the flow of slurry and minimizing turbulence, which can lead to inefficiencies and wear.

4. Suction and Discharge Flanges These flanges allow for the connection of piping systems to the pump. They are meticulously designed to ensure a tight seal, preventing leaks and ensuring that the necessary flow is maintained.

5. Mechanical Seal The mechanical seal prevents slurry leakage from the pump. Warman provides various sealing options, such as single and double seals, that can be customized according to the specific application's requirements. Proper maintenance of the mechanical seal is vital to prevent wear and prolong the life of the pump.

warman slurry pump parts

6. Bearing Assembly The bearing assembly supports the rotating shaft and ensures smooth operation. It typically includes various components like bearings, end covers, and grease fittings. Selecting the right type of bearing is essential for durability, especially in heavy-duty applications.

7. Shaft The shaft connects the impeller to the motor. Its design and material are crucial for transmitting torque effectively while resisting bending and torsional stresses.

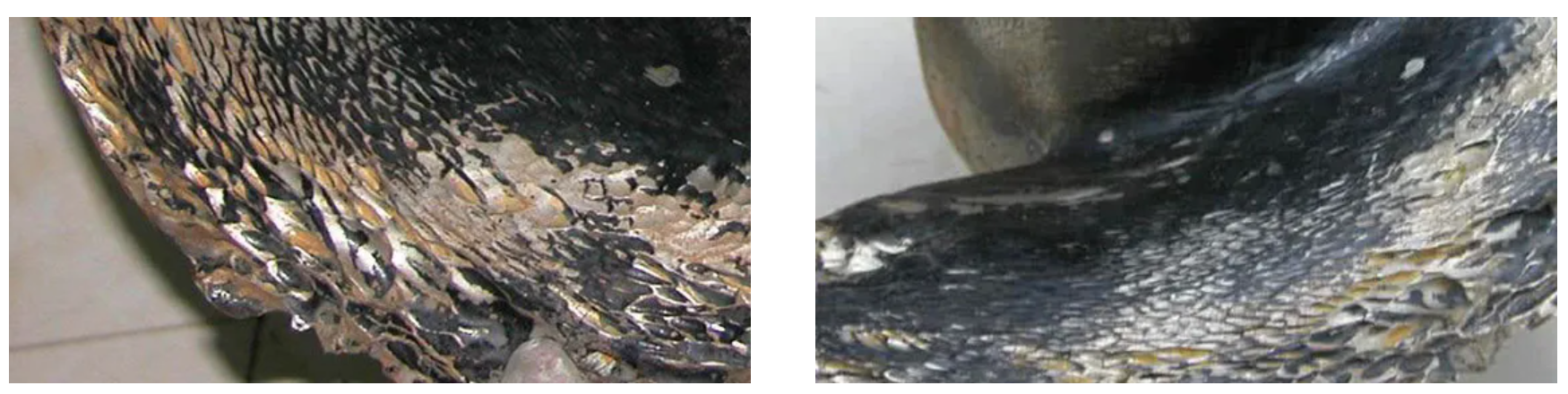

8. Liners The liners, often made of wear-resistant materials, prevent wear on the internal surfaces of the pump housing. They are replaceable and should be checked regularly for wear, as their condition directly impacts pump performance.

Importance of Maintenance

Regular maintenance of Warman slurry pump parts is essential to ensure optimal performance and longevity. Monitoring wear on the impeller and liners, checking the mechanical seal, and ensuring proper lubrication of the bearing assembly can prevent unexpected downtime and costly repairs.

Moreover, companies should consider using genuine Warman replacement parts, as these are specifically designed to meet the pump's operational demands. Through proper maintenance and timely replacement of worn components, operators can significantly enhance the pump's efficiency and reduce the likelihood of failures.

Conclusion

Warman slurry pumps play a vital role in transporting challenging materials in various industrial sectors. Understanding the individual parts that make up these pumps can help operators maintain their systems effectively. By focusing on quality components and regular maintenance, users can ensure their Warman slurry pumps operate reliably and efficiently, thereby maximizing productivity and minimizing costs in the long run.

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025