ທ.ວ. . 11, 2024 10:25 Back to list

Types of Slurry Pump Impellers and Their Applications in Industrial Processes

Understanding Slurry Pump Impeller Types A Comprehensive Guide

Slurry pumps are essential components in various industries, particularly in mining, mineral processing, and wastewater treatment. They are designed to handle abrasives and viscous fluids, crucial in transporting slurries that comprise solids suspended in a liquid. The efficiency and effectiveness of a slurry pump largely depend on its impeller type. In this article, we will explore the different types of slurry pump impellers and their applications, helping you understand how to select the right one for your needs.

What is a Slurry Pump Impeller?

The impeller is a rotating component of a pump that transfers energy to the fluid, increasing its pressure and flow rate. In the case of slurry pumps, the impeller must withstand harsh conditions, including high wear rates from abrasive materials. The design of the impeller can significantly influence the performance, efficiency, and durability of the pump, making it critical to select the appropriate type.

Types of Slurry Pump Impellers

1. Open Impellers Open impellers consist of blades that do not have any shrouds or coverings. This design allows for easy passage of large solids and makes them suitable for slurries with high solids content. The advantage of open impellers is that they can handle a variety of slurry types, including those with inconsistent particle sizes. However, they are more susceptible to wear and may require more frequent maintenance in abrasive conditions.

2. Semi-Open Impellers Semi-open impellers feature blades that are partially enclosed, providing a balance between the performance of open and closed impellers. This design allows for better efficiency and reduced wear compared to open impellers while still enabling passage of larger particles. Semi-open impellers are often used in applications where slurries may contain both large and small solids, making them versatile for various industrial processes.

3. Closed Impellers Closed impellers are fully shrouded, with blades located between two shrouds. This design allows for greater hydraulic efficiency and fluid velocity, making closed impellers ideal for applications requiring high flow rates and pressures. However, they are less effective in handling large solids due to the confined space, which could potentially clog the pump. Closed impellers are commonly used in more refined slurries with smaller particle sizes.

4. Vortex Impellers Vortex impellers are designed to create a rotating vortex, allowing for the movement of fluids. They are particularly suitable for slurries containing fibrous materials or large particles that could obstruct traditional impellers. The vortex action minimizes turbulence and ensures smooth operation while handling challenging materials. But it's important to note that vortex impellers may not achieve high efficiencies compared to other impeller types.

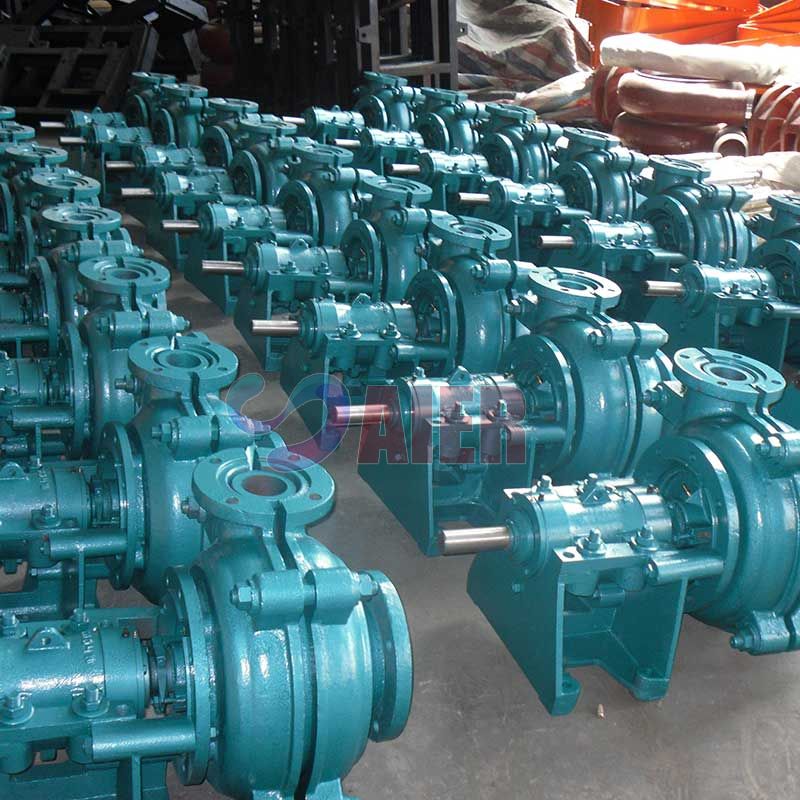

slurry pump impeller type factory

5. Progressive Cavity Impellers Although not technically an impeller in the traditional sense, progressive cavity pumps work on a different principle and can be considered when dealing with viscous slurries. They utilize a rotating helical screw to transport the slurry, making them effective for applications where shear-sensitive materials are involved. They excel in handling thick slurries, although they may require more initial investment and maintenance.

Factors to Consider When Selecting an Impeller Type

Choosing the right impeller for a slurry pump involves several considerations

- Slurry Composition Understand the nature of the slurry, including particle size, shape, and concentration. This will determine which impeller type can best handle the solid load.

- Chemical Properties The corrosive nature of the slurry will affect material selection for the impeller. Some materials offer better resistance and longevity than others.

- Operational Conditions Consider the operating environment, including temperature, pressure, and flow rates, to ensure optimal performance.

- Maintenance and Service Life Evaluate the ease of maintenance and service life expectations for the impeller type chosen. Some designs may require more frequent replacements depending on wear characteristics.

Conclusion

Slurry pump impellers play a crucial role in the efficient transportation of slurries across various industries. Understanding the different types of impellers and their specific applications allows for informed decision-making when selecting a slurry pump. By carefully assessing the slurry characteristics and operational requirements, operators can enhance pump efficiency, reduce maintenance costs, and ensure the longevity of the pumping system. With the right slurry pump impeller, you can achieve optimal performance in even the most challenging pumping conditions.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025