Aug . 07, 2024 18:15 Back to list

High-Performance Submersible Slurry Pump Manufacturing Facility for Diverse Industrial Applications

The Importance and Functionality of Submersible Slurry Pump Factories

In the industrial landscape, the movement of liquids, particularly those containing solid particles, is a vital process that impacts various sectors, including mining, construction, and wastewater management. At the heart of this operation is the submersible slurry pump, a robust and efficient device designed to handle the challenges posed by thick, viscous materials. Behind these critical machines lies the essential role of submersible slurry pump factories, which serve as the breeding ground for innovation, quality production, and advancements in pumping technology.

What is a Submersible Slurry Pump?

A submersible slurry pump is a type of pump that is submerged in the liquid it is pumping. This design helps to minimize cavitation, reduce the risk of damage from air exposure, and optimize the efficiency of the pumping process. These pumps are primarily used to transport slurry, a mixture of liquid and solids, making them particularly essential in industries dealing with mining sludge, aggregates, construction materials, and sewage.

These pumps are engineered to be durable and resistant to wear and tear, often constructed with high-quality materials such as stainless steel, which can withstand corrosion and other harsh conditions. The unique design facilitates easy operation and maintenance, ensuring that they can handle the most challenging tasks without frequent downtime.

The Role of Submersible Slurry Pump Factories

Submersible slurry pump factories are integral to the manufacturing process, playing several key roles

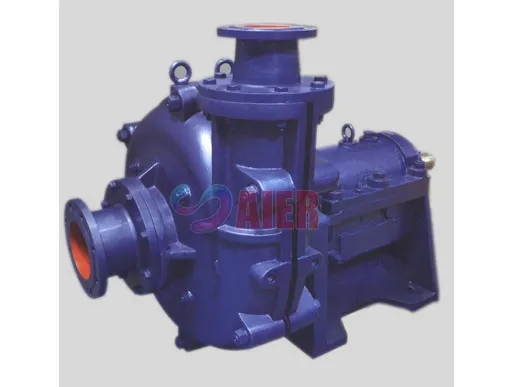

submersible slurry pump factory

1. Research and Development These factories often invest heavily in R&D to keep up with advancements in technology and to better meet the evolving needs of industry. Innovations such as improved impeller designs, energy-efficient mechanisms, and smart pump technology are often developed in these settings, ensuring that modern pumps deliver superior performance.

2. High-Quality Production Manufacturing a submersible slurry pump requires precision engineering and high-quality materials. Factories prioritize stringent quality control processes to ensure that every pump meets industry standards. This often includes thorough testing for pressure, flow rate, and durability to guarantee reliability and efficiency in real-world applications.

3. Customization Different industries have unique requirements regarding flow rate, viscosity, and the types of solids present in the slurry. Submersible slurry pump factories are adept at creating customized solutions that cater to specific needs, offering a range of models that can vary in size, capacity, and design characteristics.

4. Sustainability As industries worldwide move toward more sustainable practices, submersible slurry pump factories are also focusing on eco-friendly manufacturing processes. This includes reducing waste, minimizing energy consumption, and developing pumps that are more efficient, thus reducing the carbon footprint of operations.

5. After-Sales Support The relationship between manufacturers and end-users does not end with the sale of a pump. Reputable slurry pump factories provide extensive after-sales support, including maintenance services, technical support, and the provision of spare parts. This ongoing relationship is vital for ensuring longevity and optimal performance in harsh conditions.

Conclusion

Submersible slurry pump factories are crucial to ensuring that industries reliant on the movement of slurry can operate efficiently and effectively. Through innovation, quality manufacturing, and dedicated support, these factories contribute significantly to the overall performance of pumping systems. As global demand for efficient and sustainable industrial solutions continues to rise, the role of submersible slurry pump factories will undoubtedly become even more significant in shaping the future of fluid transportation across various sectors.

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025