Sep . 28, 2024 20:43 Back to list

Choosing the Right Impeller Type for Slurry Pumps in Various Applications

Understanding Slurry Pump Impeller Types

Slurry pumps play a critical role in various industries, particularly where the transportation of abrasive materials and thick mixtures is necessary. These pumps are designed to handle heavy, viscous fluids that typically contain solid particles. One of the most crucial components of a slurry pump is its impeller, which directly influences the pump’s efficiency, durability, and overall performance. In this article, we will explore the different types of impellers used in slurry pumps, their unique characteristics, and how they can affect the pump's operation.

Types of Impellers

1. Open Impellers Open impellers are characterized by their lack of a back shroud, allowing the slurry to flow freely through the impeller. This design reduces the risk of blockage and is suitable for pumping fluids with a high concentration of solids. They are generally easier to maintain and clean, making them ideal for applications where downtime needs to be minimized. However, open impellers may struggle with efficiency at high speeds and could have a shorter lifespan due to increased wear from abrasive materials.

2. Closed Impellers Closed impellers feature a shroud on both the front and back sides, providing better control over the flow and pressure of the fluid. These impellers are more efficient than their open counterparts at higher speeds, as they can generate greater pressure. Closed impellers are preferred in applications where a stable flow is essential, and they are designed to handle slurries with lower solid content. However, they can be more susceptible to clogging when dealing with thick, highly viscous materials.

3. Semi-Open Impellers As a hybrid between open and closed impellers, semi-open impellers have a partial shroud that retains some of the benefits of both designs. They are known for their versatility, as they can manage a wide variety of slurries with different solid contents. Semi-open impellers provide a good balance of efficiency and resistance to clogging, making them a popular choice for many industries.

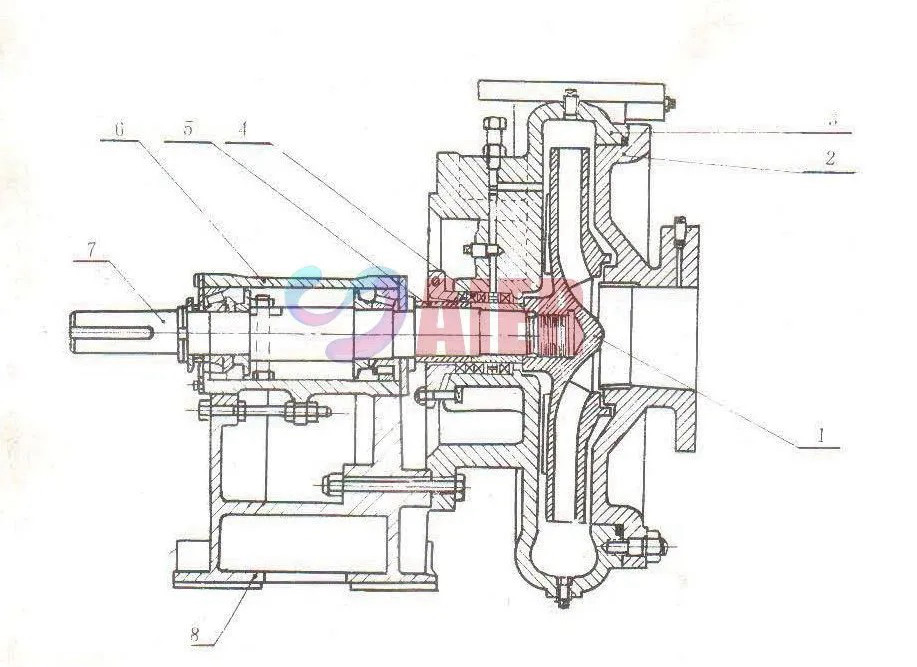

slurry pump impeller type

4. Vortex Impellers Vortex impellers are designed specifically for handling highly viscous slurries and thick fluids that contain large solids. They create a swirling motion that helps prevent solids from settling and ensures a consistent flow. This type of impeller is particularly effective in applications that involve abrasive materials, as it reduces wear and tear on the pump components. Vortex impellers may not be as efficient in terms of pressure generation but excel in maintaining flow consistency.

Factors Influencing Impeller Selection

Choosing the right impeller type for a slurry pump involves considering several factors, including the nature of the slurry, the concentration of solids, the desired flow rate, and the operating conditions. Applications in mining, wastewater treatment, and chemical processing often require specific considerations regarding abrasive wear and the size of solid particles.

It's vital to engage with manufacturers and suppliers who can provide insight into the best impeller designs for particular applications. Factors such as material composition, pump speed, and energy consumption also play significant roles in this decision-making process.

Conclusion

In conclusion, the selection of the appropriate impeller type is fundamental to the operational success of slurry pumps. Open, closed, semi-open, and vortex impellers each offer distinct advantages depending on the specific needs of the application. An informed choice can lead to improved efficiency, reduced maintenance costs, and enhanced lifespan of the pump. Thus, understanding these differences is essential for industries relying on slurry pumps for their operations. By choosing the right impeller, businesses can ensure optimal performance and reliability in transporting challenging materials.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025