Dec . 29, 2024 05:52 Back to list

Top Manufacturers of High-Quality Slurry Pumps with Superior Impeller Design

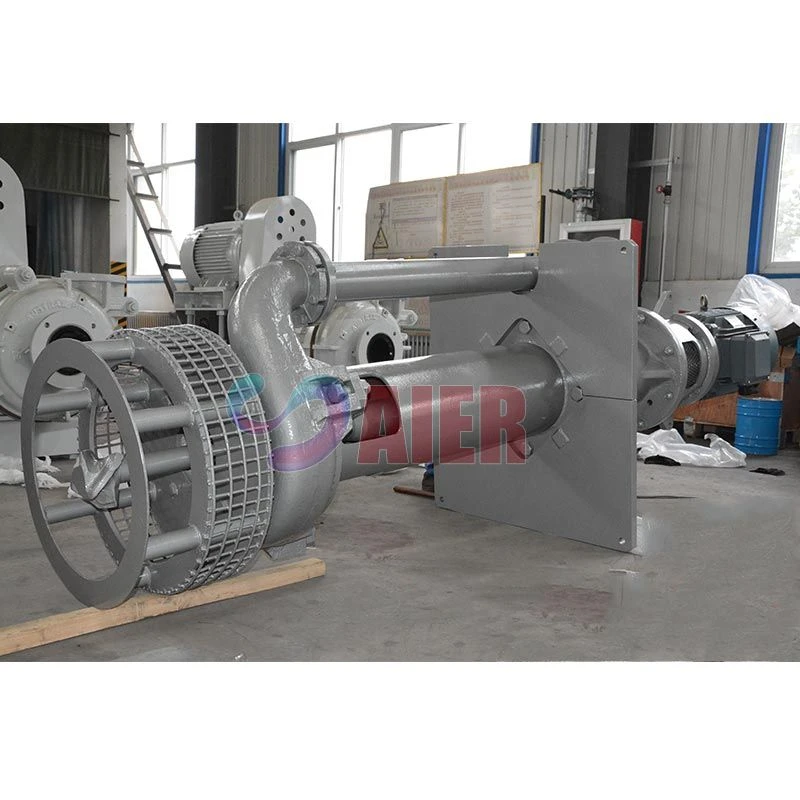

High-Quality Impeller Slurry Pump Manufacturers A Comprehensive Guide

In the industries of mining, chemical processing, and wastewater management, slurry pumps are essential components for transporting abrasive and viscous fluids. Among the key elements that determine the performance and longevity of these pumps is their impeller. The role of the impeller in a slurry pump is to impart velocity to the slurry, making the choice of an effective and reliable impeller crucial. Consequently, high-quality impeller slurry pump manufacturers play a significant role in the industry, providing solutions that enhance efficiency and reduce operational costs.

Understanding Slurry Pumps and Their Importance

Slurry pumps are specifically designed to handle a mixture of solid particles and liquids, known as slurry. The applications for these pumps vary from transferring tailings in mining operations to managing sludge in wastewater treatment facilities. The abrasive nature of slurries necessitates the use of pumps made from durable materials and equipped with efficient impeller designs that can withstand wear and tear.

The impeller, being the rotating component of the pump, directly affects the pump's performance, energy consumption, and lifespan. A well-designed impeller can significantly improve flow rates and reduce maintenance needs, making the selection of an appropriate manufacturer essential for operational success.

Characteristics of High-Quality Impeller Slurry Pump Manufacturers

1. Material Innovation The best manufacturers invest in research and development to create impellers using advanced materials. These materials often exhibit superior wear resistance, corrosion resistance, and mechanical strength. Common materials include high chromium alloys, rubber linings, and even ceramic composites for certain applications.

2. Engineering Expertise High-quality manufacturers employ a team of skilled engineers who understand the intricacies of fluid dynamics and material science. These experts typically use advanced simulation software during the design phase, allowing them to create impellers that optimize hydraulic efficiency while minimizing energy consumption.

3. Customization Options Many leading slurry pump manufacturers offer custom solutions tailored to specific customer needs. Whether a particular size, shape, or material is required, customization ensures that the impeller performs optimally in its designated application.

high quality impeller slurry pump manufacturers

4. Quality Control Rigorous quality control measures are characteristic of reputable manufacturers. They often utilize testing facilities to conduct extensive performance and durability tests on their products. This assurance allows customers to trust that they are investing in pumps that meet industry standards.

5. After-Sales Support A reliable manufacturer not only supplies pumps but also provides exceptional after-sales support. This includes installation assistance, maintenance services, and readily available spare parts, ensuring long-term operational efficiency.

The Global Market for Impeller Slurry Pumps

The demand for high-quality impeller slurry pumps is driven by various industry sectors, leading to a competitive global market. Regions with booming mining activities, such as South America, Australia, and parts of Africa, regularly seek advanced slurry pump technologies. Similarly, the growing emphasis on sustainable practices has also propelled the need for efficient pump systems that can handle waste products while minimizing environmental impact.

With the increase in automation and digital technologies, some manufacturers are incorporating IoT (Internet of Things) capabilities into their slurry pumps. This allows for real-time monitoring of pump performance, enabling predictive maintenance and reducing downtime.

Conclusion

The selection of a high-quality impeller slurry pump manufacturer is a critical decision for any operation dealing with slurries. With the potential to enhance efficiency, reduce costs, and ensure reliability, choosing the right manufacturer can lead to significant competitive advantages across various industries. As technology continues to advance, the collaboration between manufacturers and engineers will be vital in addressing the challenges posed by modern slurry applications, driving innovation in pump design and functionality.

Investing in a quality manufacturer means investing in the future of your operations. The combination of superior materials, engineering expertise, customization options, and strong after-sales support can make all the difference in achieving operational success. With the right partner, you can navigate the complexities of slurry transport with confidence and precision.

-

Small Dredger and Marine Pontoon - Aier Machinery | Dredging Solutions, Waterway Management

NewsAug.05,2025

-

Small Dredger and Marine Pontoon - Aier Machinery | Gold Mining Equipment, Industrial Dredging Systems

NewsAug.05,2025

-

Small Dredger and Marine Pontoon- Aier Machinery Hebei Co., Ltd|Cost-Effective Solutions&High-Efficiency Dredging

NewsAug.05,2025

-

Submersible Pump Impeller Manufacturer | GPT-4 Turbo Series

NewsAug.05,2025

-

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

NewsAug.04,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025