ಡಿಸೆ . 12, 2024 03:18 Back to list

thick slurry pump factory

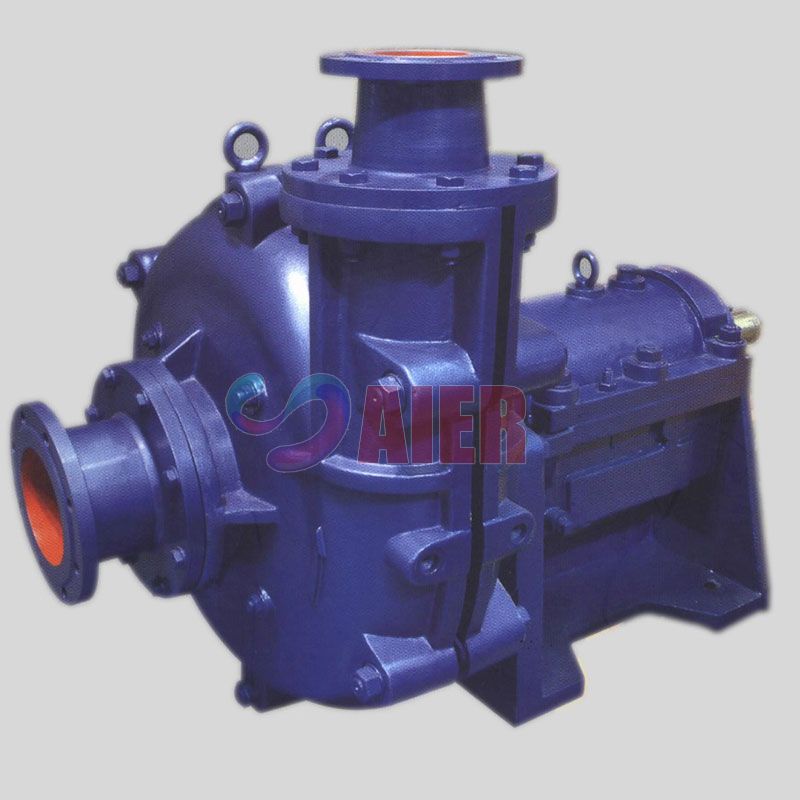

Understanding Thick Slurry Pumps Insights from the Factory

Thick slurry pumps play a crucial role in various industries, particularly in mining, construction, and wastewater management. As a key component in the transportation of thick, viscous slurries—mixtures of solids and liquids—these pumps are designed to handle materials that are often abrasive and difficult to process. This article delves into the design, manufacturing, and application of thick slurry pumps, providing insights into factory operations and the technology involved.

The Importance of Thick Slurry Pumps

In industries such as mining, the need for effective transportation of slurries is paramount. These slurries can include ore particles, coal, and other materials mixed with water, which need to be moved from one location to another with minimal loss and maximum efficiency. Thick slurry pumps are engineered to manage these challenging conditions, allowing for the smooth transfer of materials without clogging or damaging the pump itself.

The demand for thick slurry pumps has prompted factories to adopt innovative manufacturing techniques. Engineers and technicians work tirelessly to ensure that these pumps can meet the rigorous demands of heavy industries. This includes selecting materials that can withstand the wear and tear associated with transporting abrasive slurries.

Manufacturing Process

The manufacturing process of thick slurry pumps involves several critical stages

1. Material Selection The first step is choosing the right materials. Commonly used materials include high-chrome iron, rubber, and certain composites designed specifically to resist abrasion and corrosion.

2. Design and Engineering Engineers use sophisticated software to design pumps that optimize flow and efficiency. This phase is crucial as it determines the pump's effectiveness when dealing with thick materials.

thick slurry pump factory

3. Casting and Machining Once the design is finalized, the components of the pump are cast and machined. This is a precise process that requires skilled labor and advanced machinery to ensure that each part meets strict tolerances.

4. Assembly After machining, the components are brought together in a clean, organized assembly line. Each pump undergoes rigorous testing at this stage to check for leaks, functionality, and durability.

5. Quality Control The final step before a pump is shipped out involves comprehensive quality control measures. This includes testing the pumps under real-world conditions to ensure they perform reliably under operational stresses.

Applications of Thick Slurry Pumps

Thick slurry pumps are indispensable across a range of applications. In the mining industry, they are used to move slurries from crushing and grinding operations to processing facilities. In construction, they assist in the transportation of concrete mixtures and other heavy materials. Wastewater treatment facilities also rely on thick slurry pumps for the effective movement of effluent and sludge.

The versatility of these pumps cannot be overstated. They are available in various configurations, including horizontal and vertical designs, depending on the specific requirements of the application. Moreover, advancements in technology such as variable speed drives and automation are enhancing the operational efficiency of thick slurry pumps, making them even more effective in challenging environments.

Conclusion

In conclusion, the factory behind thick slurry pumps is a hub of innovation and technical excellence. Through meticulous design, careful material selection, and advanced manufacturing processes, these pumps are crafted to meet the demanding needs of various industries. As technology continues to evolve, the future of thick slurry pumps looks promising, with continuous improvements aimed at enhancing their performance and durability. The importance of these pumps in industrial applications underscores their integral role in facilitating smooth operations and achieving efficiency in transport processes.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025