ಸೆಪ್ಟೆಂ . 22, 2024 01:15 Back to list

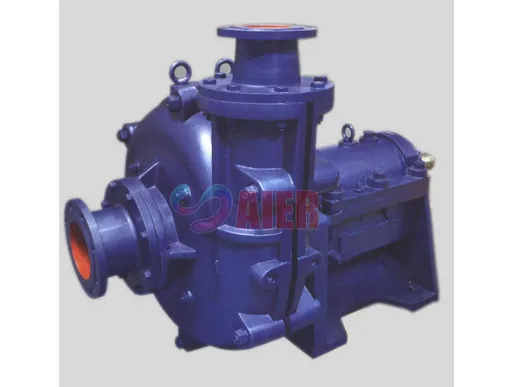

single stage vertical slurry pump supplier

The Importance of Single Stage Vertical Slurry Pumps in Various Industries

In various industrial applications, the efficient transport of slurry—a mixture of liquid and solid materials—plays a critical role in operations. One of the most effective types of pumps for handling such challenging tasks is the single stage vertical slurry pump. These specialized pumps are designed to manage thick, viscous slurries often found in mining, construction, and wastewater treatment industries.

Understanding Single Stage Vertical Slurry Pumps

Single stage vertical slurry pumps are characterized by their vertical orientation, meaning the pump shaft is positioned upright. This design enhances the pump’s ability to manage heavy slurries efficiently. Unlike horizontal pumps that may struggle with sedimentation and clogging, vertical pumps minimize these risks due to their design. The pump’s impeller, located below the surface of the slurry, ensures that solids settle at the bottom while still allowing for effective flow and movement.

Benefits of Using Single Stage Vertical Slurry Pumps

1. Space Efficiency These pumps are ideal for environments with limited space. Their vertical design allows them to be installed in tight areas, conserving valuable floor space.

2. Reduced Pumping Costs Single stage vertical slurry pumps are generally more energy-efficient than their horizontal counterparts. With fewer components and a streamlined design, they require less energy to operate, which translates to lower operational costs.

3. Durability and Reliability Designed to handle abrasive and corrosive materials, these pumps are often constructed from high-quality materials such as cast iron, stainless steel, or other alloys. This durability ensures a longer lifespan and reduced maintenance needs.

single stage vertical slurry pump supplier

4. Versatility Single stage vertical pumps can be utilized in various applications, making them suitable for a range of industries. From transporting coal slurry in mining operations to handling sludge in wastewater treatment, their versatility is a key benefit.

5. Reduced Wear and Tear The hydraulic design of these pumps helps reduce wear and tear on internal components. Since they can handle high concentrations of solids, the potential for damage is minimized, leading to improved operational efficiency.

Choosing a Reliable Supplier

Selecting the right supplier for single stage vertical slurry pumps is crucial. A trusted supplier should not only provide high-quality products but also offer expert advice and support tailored to your specific application. When considering a supplier, look for the following

- Reputation Research the supplier's history in the industry. A well-established supplier with positive reviews is likely to deliver reliable products.

- Product Range Ensure the supplier offers a variety of pump models to suit your specific needs. This flexibility is important for addressing different slurry types and operational requirements.

- After-Sales Support Good suppliers offer robust after-sales support, including technical assistance, maintenance resources, and replacement parts availability.

In conclusion, single stage vertical slurry pumps are indispensable in many industries requiring efficient slurry handling. With their space-saving designs, energy efficiency, and robust performance, these pumps are a vital investment for businesses looking to optimize their operations. Selecting a reliable supplier is essential to ensuring that you gain the full benefits these pumps can offer.

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025