ಡಿಸೆ . 01, 2024 15:24 Back to list

industrial vertical sump pump supplier

Understanding Industrial Vertical Sump Pumps and Their Suppliers

Industrial vertical sump pumps play a critical role in various applications, particularly in the management of liquids with a high solid content or in contexts where space constraints limit the installation of traditional horizontal pumps. These pumps are specifically designed to operate under submerged conditions, efficiently moving water, sludge, and other fluids from sump pits or basins to desired discharge points. Understanding their design, functionality, and sourcing from reputable suppliers is essential for industries relying heavily on fluid management systems.

What is a Vertical Sump Pump?

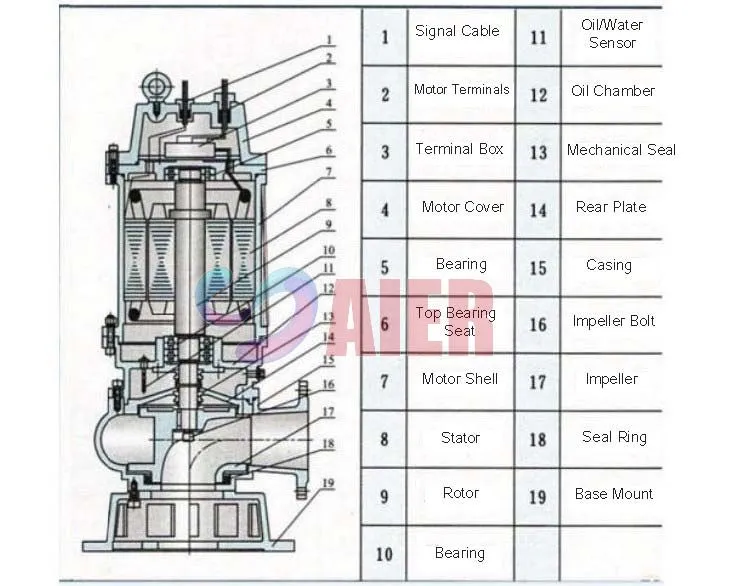

A vertical sump pump is characterized by its vertical orientation, which allows it to be installed directly within a sump or pit. Unlike horizontal pumps, vertical models use a motor positioned above the fluid level, connected to an impeller that is submerged. This design helps minimize the footprint of the pump, making it ideal for confined spaces. Additionally, many vertical sump pumps are built with features that protect them from damage due to the harsh environments often found in industrial settings.

These pumps are particularly effective at handling mixtures of liquid and solids, making them a favorite in industries such as mining, wastewater treatment, and construction. They can handle fluids that contain abrasive materials, corrosive substances, and large particulates without compromising performance or longevity.

Key Features and Benefits

1. Space Efficiency The vertical design allows for installation in tight spaces where traditional pumps may not fit. This is particularly valuable in facilities where space is a premium.

2. Robust Construction Industrial vertical sump pumps are often built with high-quality materials that can withstand harsh operating conditions, including high temperatures and corrosive environments.

4. Ease of Maintenance Many models are designed for easy maintenance, allowing for quick inspections and repairs without the need for extensive downtime.

5. Customization Suppliers often provide customization options for vertical sump pumps according to specific industrial requirements, ensuring that the pumps are equipped to handle unique challenges.

industrial vertical sump pump supplier

Choosing the Right Supplier

When it comes to procuring industrial vertical sump pumps, selecting the right supplier is crucial. Several factors should be considered

- Experience and Reputation Look for suppliers with a proven track record in the industry. Established suppliers are more likely to understand the complexities of your requirements and can offer better support.

- Quality of Products Assess the quality of the pumps offered. Look for certifications and standards that indicate reliability and performance, such as ISO standards.

- After-Sales Support Choose suppliers that offer robust after-sales services, including installation assistance, maintenance, and spare parts availability. This ensures that you have support throughout the lifespan of the pump.

- Customization Capabilities Ensure the supplier can provide pumps that can be tailored to your specific needs, including size variations, motor types, and materials suited to your specific applications, especially if you are dealing with corrosive or abrasive fluids.

- Competitive Pricing While cost should not be the only factor, it is important to compare prices. Look for a supplier that provides a balance between quality and price.

- Customer Reviews and Testimonials Research customer feedback or seek testimonials from other industries to gauge the supplier's credibility and the performance of their pumps.

Conclusion

Industrial vertical sump pumps are an essential component in many sectors, offering efficient solutions for fluid management in confined spaces. When selecting a supplier, it is important to consider factors such as experience, product quality, and customization options to ensure you are making a sound investment. By partnering with the right supplier, industries can enhance operational efficiency, reduce downtime, and maintain effective fluid management systems to support their business processes. Whether for construction, wastewater treatment, or heavy industry applications, the right vertical sump pump can make all the difference in performance and reliability.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025