ធ្នូ . 09, 2024 17:48 Back to list

Slurry Pump Manufacturer and Supplier of Replacement Parts for Optimal Performance

Understanding Slurry Pumps and the Importance of Spare Parts Manufacturing

Slurry pumps are an essential component in various industries involving the transportation of thick, viscous mixtures, commonly known as slurries. These pumps are designed to handle liquids laden with minerals, coal, sand, or other particulate matter. The functioning and longevity of slurry pumps depend not only on their design and construction but also on the quality and availability of their spare parts.

The Role of Slurry Pumps

Slurry pumps are widely used across different sectors, including mining, mineral processing, sewage treatment, and construction. Their primary function is to move slurries efficiently while minimizing wear and tear on the pump itself. Unlike standard pumps, slurry pumps are specifically engineered to manage higher concentrations of solids, making them vital for operations that require the transportation of materials like coal and ores.

These pumps are built with robust materials that can withstand the abrasive nature of slurries. Common features include a heavy-duty casing and hardened impellers that offer resistance to wear. This durability is crucial, as the wear and tear of a pump can lead to increased operational costs, downtime, and the need for frequent maintenance.

Importance of Spare Parts

The functionality of slurry pumps heavily relies on their spare parts. Over time, components such as impellers, liners, seals, and bearings can become worn and may need replacement to ensure the pump operates at peak efficiency. Access to high-quality spare parts is vital for minimizing downtime and maintaining the smooth operation of machinery.

Manufacturers of slurry pumps play a critical role in producing not only the pumps but also the spare parts that are necessary for their maintenance. High-quality spare parts must match the original specifications of the pumps to ensure compatibility and superior performance. As such, a reliable source for these components is critical.

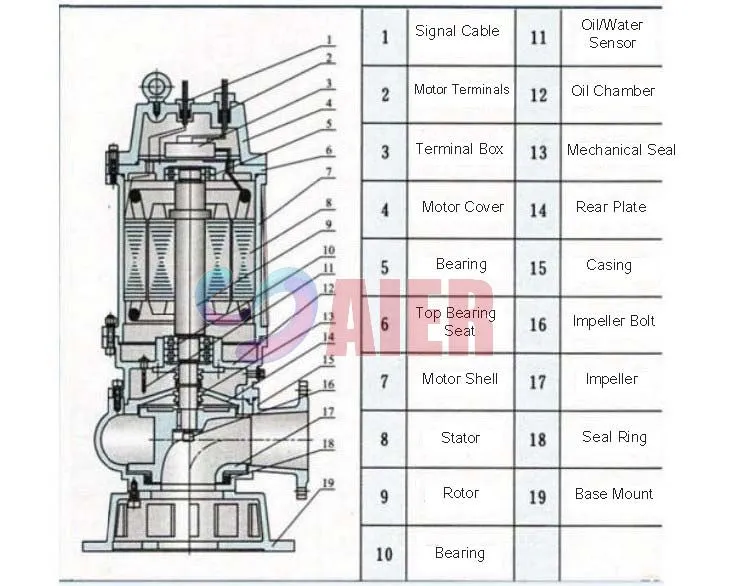

slurry pump and spare parts manufacturer

Manufacturing Spare Parts

The manufacturing of spare parts for slurry pumps involves specialized processes. Companies must use durable materials that can withstand harsh environments and prolonged use. The manufacturing process often incorporates techniques such as precision casting, machining, and heat treatment to enhance the strength and wear resistance of parts.

Quality control is paramount in this context. Manufacturers must adhere to strict regulations and industry standards to ensure that their products meet the necessary performance criteria. Comprehensive testing helps in identifying any potential shortcomings in the parts, thereby offering assurance regarding their longevity and efficiency.

Furthermore, advancements in technology, such as 3D printing, are beginning to revolutionize the production of spare parts for slurry pumps. This innovation enables faster prototyping and production, which can significantly reduce lead times. The ability to produce parts on demand also addresses the critical aspect of inventory management, allowing manufacturers to respond quickly to market needs.

Conclusion

In conclusion, slurry pumps are indispensable in industries that deal with the transportation of slurries. Their ability to operate efficiently in challenging conditions is matched by the necessity for high-quality spare parts. The manufacturing of these spare parts is a specialized domain that requires precision, adherence to industry standards, and an understanding of the operational demands of slurry pumps.

As industries continue to evolve, the collaboration between slurry pump manufacturers and spare parts producers will be key to advancing technology and enhancing the efficiency of operations. By ensuring the availability of top-quality components, manufacturers can significantly reduce downtime, improve operational longevity, and ultimately contribute to the success of the industries that rely on these vital pumps. With the ever-increasing demand for efficiency and reliability in industrial processes, the future of slurry pumping and spare parts manufacturing looks promising, paving the way for new innovations and enhanced operational capabilities.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025