វិច្ឆិកា . 06, 2024 23:05 Back to list

china centrifual slurry pump spare parts factory

Exploring China’s Centrifugal Slurry Pump Spare Parts Factory

In the dynamic world of industrial manufacturing, the need for reliable and efficient equipment is paramount, especially in sectors handling abrasive and corrosive materials, such as mining, construction, and chemical processing. Central to these operations is the centrifugal slurry pump, designed to transport slurry consisting of liquids and solid particles. The performance and durability of these pumps greatly depend on the quality of their spare parts, leading to a burgeoning industry in China focused on the production of these essential components.

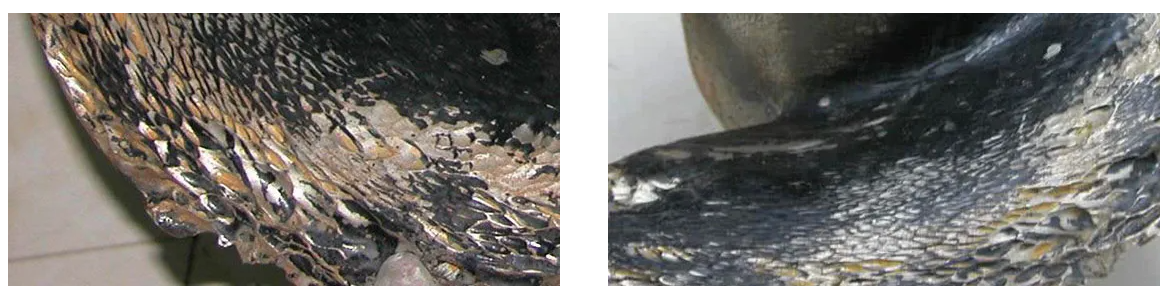

China has emerged as a global leader in manufacturing and supplying centrifugal slurry pump spare parts. The country possesses a robust industrial base, equipped with advanced technology and skilled labor. Factories dedicated to producing spare parts for these pumps are strategically located in various regions, benefiting from proximity to raw materials and transportation networks. These factories focus on producing high-quality components, including impellers, casing, liners, and shafts, which are critical for the efficient functioning of slurry pumps.

One of the significant advantages of sourcing slurry pump spare parts from China is the cost-effectiveness. Chinese manufacturers are known for their ability to produce high-quality products at competitive prices, thanks to lower labor costs and efficient production processes. This affordability is particularly beneficial for companies operating in cost-sensitive industries, allowing them to maintain their equipment without straining their budgets.

china centrifual slurry pump spare parts factory

Quality control is another critical aspect of the manufacturing process in Chinese factories. Many of these facilities have adopted international standards and certifications, such as ISO 9001, ensuring that their products meet global quality benchmarks. Rigorous testing and quality assurance processes are implemented to guarantee that spare parts can withstand the demanding conditions of slurry transport. By utilizing advanced materials and engineering techniques, these manufacturers enhance the durability and performance of their products.

The importance of timely availability cannot be overstated in industries relying on slurry pumping systems. Downtime due to equipment failure can lead to significant financial losses. Chinese spare parts manufacturers typically maintain sufficient inventory levels and employ efficient logistics strategies to ensure quick delivery times, allowing clients to minimize downtime and keep their operations running smoothly. This agility in supply chain management has made Chinese factories a preferred choice for companies worldwide.

Furthermore, many of these factories are committed to continuous improvement and innovation. They invest in research and development to create new materials and designs that enhance the efficiency and lifespan of slurry pump components. Collaboration with industry experts and customers allows these manufacturers to stay ahead of market trends and continuously improve their offerings.

In conclusion, China’s centrifugal slurry pump spare parts factories play a crucial role in supporting industrial operations globally. With a focus on cost-effectiveness, quality control, timely delivery, and continuous innovation, these manufacturers are well-positioned to meet the demands of various sectors. As industries evolve, the importance of reliable and efficient slurry pump components will only increase, solidifying China's reputation as a powerhouse in this vital segment of the manufacturing industry.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025