មករា . 25, 2025 21:32 Back to list

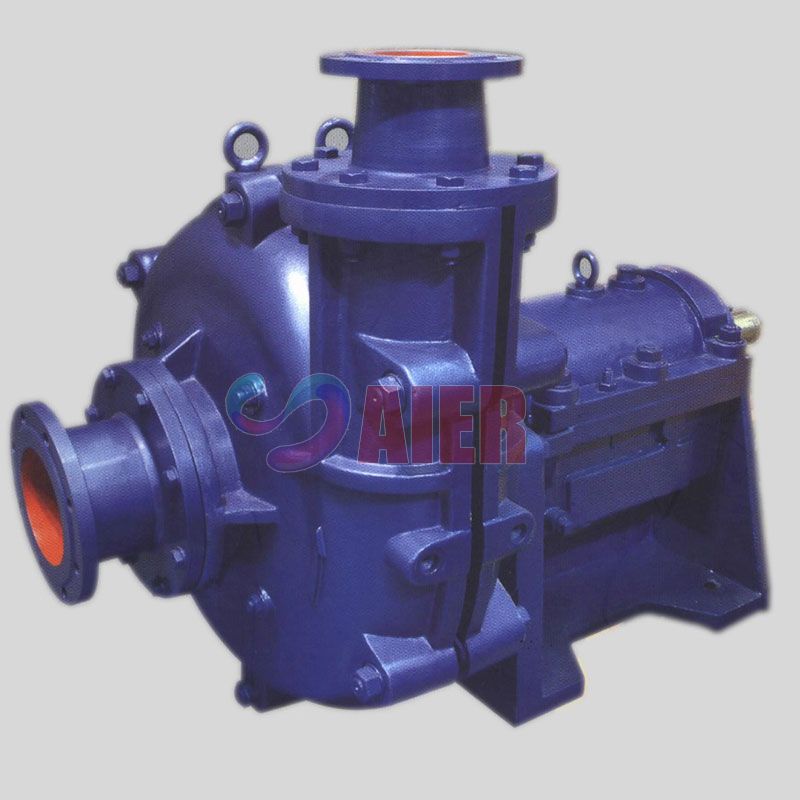

centrifugal slurry pump liner

Centrifugal slurry pump liners are crucial components in the world of industrial equipment, frequently overlooked when it comes to maintenance and understanding. With over two decades of experience working with centrifugal pumps, I can attest to the indelible role these liners play in ensuring enhanced performance, durability, and overall reliability.

Trustworthiness, the cornerstone of any high-performing industrial component, is built through rigorous testing and quality assurance measures. Leading manufacturers subject their centrifugal slurry pump liners to exhaustive tests that simulate real-world industrial conditions. This includes comprehensive abrasion testing, chemical resilience assessments, and hydraulic performance evaluations. This rigorous testing ensures that each liner is not only fit for purpose but exceeds expectations in demanding environments. Customers can further bolster their trust in these products by choosing liners that come from reputable manufacturers, those that have a proven track record and are certified by recognized industry standards. Engaging with suppliers who provide detailed product information and have robust customer support can help customers make informed decisions and develop long-term supplier partnerships. The importance of centrifugal slurry pump liners cannot be overstated. As industrial demands continue to evolve and grow, the need for components that offer exceptional durability, precision engineering, and robust performance becomes more critical. While the initial investment in a high-quality liner might be more considerable, the long-term savings on maintenance and downtime, and the reliability of operations, offset these costs impressively. In conclusion, understanding and investing in the right centrifugal slurry pump liner is not a mere operational necessity, but a strategic decision that enhances the pump’s performance, longevity, and overall cost-effectiveness. As the domains of mining, milling, and processing continue to expand, so too will the necessity for such reliable components. Investing in high-quality liners is a testament to a company’s dedication to operational excellence and sustainable profitability.

Trustworthiness, the cornerstone of any high-performing industrial component, is built through rigorous testing and quality assurance measures. Leading manufacturers subject their centrifugal slurry pump liners to exhaustive tests that simulate real-world industrial conditions. This includes comprehensive abrasion testing, chemical resilience assessments, and hydraulic performance evaluations. This rigorous testing ensures that each liner is not only fit for purpose but exceeds expectations in demanding environments. Customers can further bolster their trust in these products by choosing liners that come from reputable manufacturers, those that have a proven track record and are certified by recognized industry standards. Engaging with suppliers who provide detailed product information and have robust customer support can help customers make informed decisions and develop long-term supplier partnerships. The importance of centrifugal slurry pump liners cannot be overstated. As industrial demands continue to evolve and grow, the need for components that offer exceptional durability, precision engineering, and robust performance becomes more critical. While the initial investment in a high-quality liner might be more considerable, the long-term savings on maintenance and downtime, and the reliability of operations, offset these costs impressively. In conclusion, understanding and investing in the right centrifugal slurry pump liner is not a mere operational necessity, but a strategic decision that enhances the pump’s performance, longevity, and overall cost-effectiveness. As the domains of mining, milling, and processing continue to expand, so too will the necessity for such reliable components. Investing in high-quality liners is a testament to a company’s dedication to operational excellence and sustainable profitability.

Latest news

-

Small Dredger and Marine Pontoon- Aier Machinery Hebei Co., Ltd|Dredging Solutions, Industrial Equipment

NewsJul.30,2025

-

Small Dredger & Marine Pontoon - Aier Machinery Hebei Co., Ltd

NewsJul.30,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd. | Dredging Solutions, Material Handling

NewsJul.30,2025

-

Small Dredger and Marine Pontoon Solutions by Aier Machinery

NewsJul.30,2025

-

Small Dredger and Marine Pontoon Solutions - Aier Machinery | Reliability, Cost-Effectiveness

NewsJul.29,2025

-

Small Dredger - Aier Machinery|Marine Equipment Solutions&Gold Mining

NewsJul.29,2025