12月 . 03, 2024 17:36 Back to list

Premium Twin Casing Slurry Pump Manufacturer with High Quality Standards and Innovation

High-Quality Twin Casing Slurry Pump Factory

In the realm of industrial fluid handling, slurry pumps play a crucial role in transporting abrasive, thick, and viscous materials. Among various types of slurry pumps available in the market, twin casing slurry pumps have garnered significant attention due to their efficiency, robustness, and ability to handle challenging applications. This article explores the essential features, advantages, and manufacturing processes that define high-quality twin casing slurry pump factories.

Understanding Twin Casing Slurry Pumps

A twin casing slurry pump features a unique design that consists of two casings the outer casing and the inner casing. This dual-casing design offers several benefits, including enhanced durability, improved hydraulic efficiency, and better pressure management. The inner casing is primarily responsible for containing the slurry, while the outer casing provides structural support and protects against environmental factors.

One of the primary advantages of twin casing slurry pumps is their ability to operate under high-pressure conditions, making them ideal for various applications in mining, dredging, wastewater treatment, and other industries where abrasive liquids are prevalent. The design minimizes slurry degradation and ensures a longer service life for the pump components.

The Importance of Quality Manufacturing

When it comes to the production of twin casing slurry pumps, quality is paramount. A high-quality pump not only ensures reliable performance but also reduces maintenance costs and downtime. Quality manufacturing processes begin with the selection of raw materials. Fabrics such as high-chrome alloys, rubber, and stainless steel are commonly used due to their excellent wear resistance and corrosion protection properties.

A reputable twin casing slurry pump factory invests in advanced manufacturing technologies and equipment. State-of-the-art casting and machining methods, including CNC machining and 3D printing, are employed to produce precise and uniform components. Rigorous quality control measures are implemented at various stages of production to ensure that each pump meets industry standards and customer specifications.

Customization and Engineering Expertise

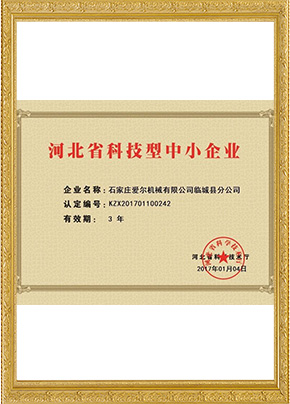

high quality twin casing slurry pump factory

A key feature of premier twin casing slurry pump factories is their ability to offer customized solutions tailored to specific customer requirements. Industries have unique needs based on the nature of the materials being transported and the operating conditions. Factories equipped with experienced engineering teams can analyze these needs and design pumps that optimize performance.

Customization may involve modifying the pump size, material choice, impeller design, or even the entire pump layout to meet specific operational demands. By collaborating closely with clients, manufacturers can deliver solutions that maximize efficiency and effectiveness.

Cost-Effectiveness and Sustainability

In today’s competitive market, cost-effectiveness is a critical consideration for buyers. High-quality twin casing slurry pumps, despite their initial investment, often result in long-term savings through reduced maintenance and operational costs. Their durability means that they require less frequent replacements, contributing to overall lower lifecycle costs.

Furthermore, leading factories are increasingly focusing on sustainable manufacturing practices. This includes using recyclable materials, minimizing energy consumption during production, and implementing waste reduction strategies. By aligning with sustainability goals, these factories not only reduce their environmental footprint but also appeal to eco-conscious customers.

Global Reach and Support

Lastly, a high-quality twin casing slurry pump factory often has a global reach. This allows them to cater to customers in various geographical locations, providing not just products but also after-sales services such as installation, maintenance, and technical support. With knowledgeable technical teams, factories can assist customers in optimizing their pump systems, ensuring they operate at peak efficiency.

Conclusion

High-quality twin casing slurry pumps are integral to numerous industrial applications, offering reliability and efficiency. The factories that specialize in their production play a critical role in ensuring that these pumps are manufactured to the highest standards. From the careful selection of materials and advanced manufacturing techniques to customization and commitment to sustainability, these factories embody innovation geared toward meeting the demands of today’s industries. As businesses continue to seek out solutions that enhance productivity and minimize operational risks, the importance of high-quality twin casing slurry pump factories cannot be overstated.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025