11月 . 23, 2024 09:02 Back to list

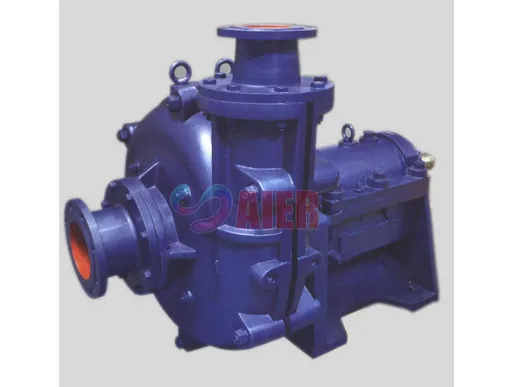

abrasives pump wastewater centrifugal pump factory

The Role of Centrifugal Pumps in Abrasive Wastewater Management

Centrifugal pumps have become indispensable in various industrial applications, particularly in the management of abrasive wastewater. Factories generating such wastewater often face significant challenges due to the presence of solid particles, which can cause clogging and damage in conventional pumping systems. Therefore, the need for specialized centrifugal pumps designed to handle abrasive materials is crucial.

Centrifugal pumps operate on the principle of converting rotational kinetic energy, provided by a rotating impeller, into hydrodynamic energy that moves the fluid. The design of these pumps makes them highly efficient for transporting liquids, including those mixed with solids. In the context of abrasive wastewater, centrifugal pumps are engineered with robust materials and features to endure the harsh conditions posed by these fluids.

The construction of a centrifugal pump designed specifically for abrasive wastewater involves the use of wear-resistant materials like hardened stainless steel or high-chrome alloy. These materials are critical in extending the life of the pump components, reducing maintenance costs, and ensuring continuous operation without significant downtime. Furthermore, many manufacturers now incorporate advanced sealing technologies and larger pump casings to accommodate higher volumes of abrasive particles and mitigate wear.

abrasives pump wastewater centrifugal pump factory

In addition to material considerations, the design and configuration of the centrifugal pump play pivotal roles in performance. Manufacturers often design pumps with adjustable speed capabilities, allowing operators to tailor the pump's performance to specific conditions. This adaptability is paramount in dealing with varying levels of abrasiveness in wastewater, optimizing efficiency, and minimizing energy consumption.

The versatility of centrifugal pumps does not stop at their physical construction. They can be fitted with various accessories and technologies, such as automatic controls and monitoring systems. These systems provide real-time data on pump performance, facilitating predictive maintenance and preventing failures before they occur. By integrating digital technologies, factories can enhance their operational efficiency and process reliability.

In summary, centrifugal pumps are vital in managing abrasive wastewater in industrial settings. Their specialized designs, constructed from durable materials, enable them to handle the challenges posed by solid particles effectively. As industries continue to confront the complexities of wastewater management, the development of advanced centrifugal pumps will play an essential role. By ensuring efficient and reliable handling of abrasive wastewater, these pumps contribute significantly to sustainable manufacturing practices and long-term operational success. The ongoing innovation in pump technology will undoubtedly enhance the performance and longevity of systems dedicated to this challenging application.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025