Set . 19, 2024 04:31 Back to list

warman slurry pump spare parts factories

Warman Slurry Pump Spare Parts Factories Meeting the Demands of Heavy Industry

In industries that require the transportation of abrasive slurries, such as mining, mineral processing, and wastewater treatment, Warman slurry pumps have established themselves as a reliable choice. These pumps are designed to handle thick, gritty fluids, which can be harsh on equipment. To maintain operational efficiency and reduce downtime, it is essential to have access to high-quality spare parts specifically designed for Warman slurry pumps. As a result, factories that specialize in manufacturing these spare parts have become integral to the supply chain of heavy industries.

One of the most significant advantages of sourcing spare parts from dedicated Warman slurry pump spare parts factories is the guarantee of quality and compatibility. These factories invest in advanced manufacturing technologies and adhere to stringent quality control measures to ensure each component meets or exceeds the specifications of original Warman parts. Businesses can reduce the risk of equipment failure by sourcing parts that are precision-engineered for specific models of Warman pumps.

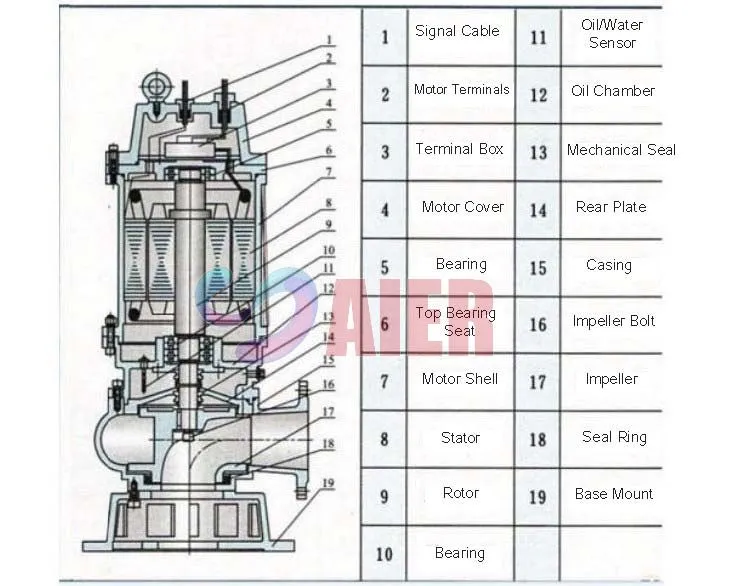

Additionally, specialized factories often offer a wide range of spare parts, including volutes, impellers, wearing plates, and shaft seals. This comprehensive inventory enables customers to find all the necessary components in one location, simplifying the procurement process. Furthermore, these factories frequently update their product lines to accommodate the latest Warman pump models and technological advancements. This means industries can always access the most current spare parts without delay, ensuring that their operations remain smooth and uninterrupted.

warman slurry pump spare parts factories

Another critical aspect of Warman slurry pump spare parts factories is their focus on research and development. By investing in R&D, these manufacturers can innovate new materials and designs that enhance the durability and efficiency of slurry pumps. For instance, advancements in wear-resistant materials can significantly increase the lifespan of pump components, thus reducing the frequency of replacements and lowering long-term maintenance costs.

The geographical presence of these factories also plays a vital role in ensuring prompt delivery and service. Many manufacturers strategically locate their operations close to key industrial hubs. This proximity enables them to respond quickly to customer requests and supply needs, making the maintenance of Warman pumps more manageable for their users.

Moreover, the rise of e-commerce and online procurement platforms has revolutionized how companies source spare parts. Many Warman slurry pump spare parts manufacturers have established an online presence, allowing customers to easily browse, order, and receive components. This convenience is especially beneficial for businesses that operate in remote locations or have limited access to local suppliers.

In conclusion, Warman slurry pump spare parts factories are essential for the efficient functioning of industries reliant on slurry pumps. By providing high-quality, compatible, and innovative components, these factories help extend the life of machinery and minimize downtime. With a focus on quality, research and development, and improved supply chains, they play a critical role in supporting the heavy industry and ensuring that operations run seamlessly. As industries continue to evolve, the role of specialized spare parts manufacturers will only become more significant in meeting the demands of modern heavy-duty applications.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025