des . 11, 2024 12:13 Back to list

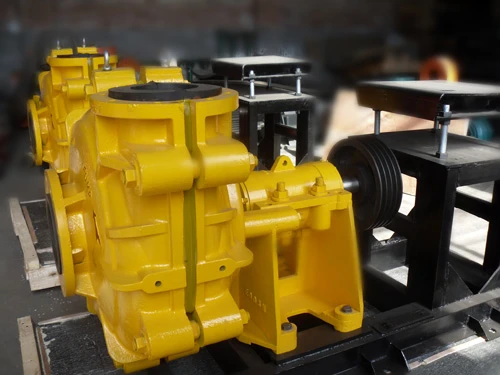

metal liner slurry pump manufacturers

The Significance of Metal Liner Slurry Pumps in Industrial Applications

In various industrial sectors, slurry pumps play a crucial role in the transportation of abrasive and viscous materials. Among the different types of slurry pumps available, metal liner slurry pumps have emerged as a popular choice due to their robust design and durability. This article will explore the importance of metal liner slurry pump manufacturers, their offerings, and the benefits these pumps provide in various applications.

Understanding Slurry Pumps

Slurry pumps are specifically engineered to handle slurries — mixtures of solid particles suspended in a liquid — which can include materials like sand, gravel, coal, and minerals. These pumps are essential in mining, mineral processing, wastewater treatment, and construction industries. The ability to efficiently transport abrasive materials without significant wear makes slurry pumps indispensable.

Importance of Metal Liners

The metal liner in a slurry pump provides the necessary strength and resistance to wear and corrosion. These liners are typically made from high-chromium alloy materials, offering superior hardness and abrasion resistance, essential for handling abrasive slurries. Unlike rubber-lined pumps, which may wear out quickly in abrasive applications, metal liner pumps maintain their performance for longer periods, reducing maintenance costs and downtime for operations.

Manufacturers and Their Offerings

Metal liner slurry pump manufacturers vary widely in terms of design, capacity, and technological advancements. Leading manufacturers focus on producing high-quality pumps tailored to specific industries and unique needs. They invest in research and development to innovate and enhance pump technology, ensuring that their products meet the evolving demands of the market.

metal liner slurry pump manufacturers

Among the world’s most recognized manufacturers are companies like Weir Minerals, SlurryPro, and Schurco Slurry, which have established a reputation for producing durable and efficient slurry pumps. These manufacturers offer a range of pump sizes, materials, and configurations, allowing customers to select the best-fit product for their specific applications. Furthermore, many manufacturers also provide customized solutions to meet unique specifications requested by their clients.

Benefits of Metal Liner Slurry Pumps

The benefits of using metal liner slurry pumps are manifold. Firstly, their durability ensures that they can withstand harsh operating conditions, reducing the frequency of replacements and repairs. This longevity correlates with lower operational costs, making them a cost-effective solution for companies that deal with slurries regularly.

Secondly, these pumps can handle a wide range of slurry types, including those with high solid concentrations and varying particle sizes. This versatility is particularly advantageous in industries such as mining and mineral processing, where conditions can frequently change.

Moreover, metal liner slurry pumps are engineered for efficiency, enabling them to maintain high flow rates while minimizing energy consumption. This efficiency not only helps in reducing operational costs but also supports environmental sustainability efforts by decreasing energy use.

Conclusion

In conclusion, metal liner slurry pumps are vital components in various industrial processes, providing the strength and durability necessary to manage abrasive materials effectively. The role of metal liner slurry pump manufacturers is significant, as they continue to innovate and supply high-quality solutions to meet the demanding needs of industries worldwide. Choosing the right manufacturer and understanding the benefits of metal liner slurry pumps can lead to improved efficiency, reduced operational costs, and enhanced productivity in slurry handling applications. As industries evolve, the importance of reliable slurry pumps will remain paramount in ensuring the smooth operation of processes that rely on the efficient transportation of slurries.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025