okt . 06, 2024 07:41 Back to list

china slurry pump warman factories

Slurry Pump Suppliers Understanding China's Warman Factories

The global industrial landscape has seen a significant reliance on slurry pumps, especially in sectors such as mining, construction, and wastewater management. Among the prominent manufacturers of these pumps are the Warman factories in China, known for their advanced technology and high production rates. This article delves into the capabilities and contributions of China’s Warman factories in the slurry pump industry.

Advanced Manufacturing Techniques

China's Warman factories utilize cutting-edge manufacturing techniques to produce slurry pumps that meet international standards. The production process employs state-of-the-art machinery and automation, enhancing both efficiency and precision. Advanced casting methods and high-quality materials, such as high chrome and rubber linings, are used to ensure durability against the abrasive and corrosive nature of slurries.

These factories also focus on research and development, continually innovating their designs to optimize performance. This commitment to technology and innovation allows them to produce pumps that not only match but often exceed the specifications needed for various industrial applications.

Quality Assurance and Certifications

Quality assurance is a critical aspect of the manufacturing process in Warman factories. Each product goes through rigorous testing to ensure reliability, efficiency, and longevity. The factories hold multiple certifications, including ISO 9001, which underscores their dedication to maintaining high-quality standards in their production processes.

Moreover, the factories employ experienced engineers and technicians who oversee the production line closely. Their expertise ensures that every pump manufactured can withstand the toughest conditions, reducing downtime and maintenance costs for their users.

china slurry pump warman factories

Diverse Product Range

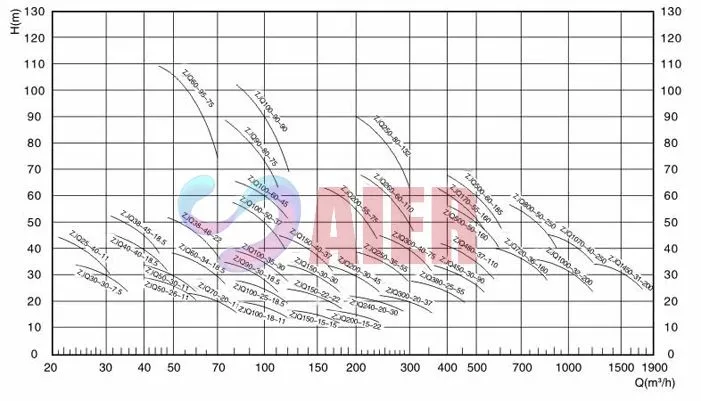

Warman factories in China offer a wide range of slurry pumps designed to accommodate different industries and applications. From horizontal and vertical pumps to submersible and dredge pumps, the product lineup is diverse. Each type is engineered for specific functions, whether it’s handling heavy-duty mining slurries or managing wastewater in treatment plants.

The customization options available allow clients to tailor pumps to their specific needs, further enhancing their operational efficiency. This flexibility makes Warman pumps a popular choice for various industries worldwide.

Global Reach and Market Presence

Warman factories have established a strong global presence, exporting their products to countries across North America, Europe, and Asia. Their ability to deliver reliable and effective solutions has earned them a reputation as a leading supplier in the slurry pump market.

In addition to their extensive distribution network, these factories are keen on customer service, offering technical support and after-sales services that are crucial for maintaining operational efficiency. This client-centric approach further solidifies their standing in the market.

Conclusion

In conclusion, China's Warman factories play a pivotal role in the slurry pump industry. Their combination of advanced manufacturing techniques, stringent quality assurance processes, and a diverse product range has placed them at the forefront of the market. As industries continue to evolve and require more efficient and reliable pumping solutions, Warman factories are well-positioned to meet these demands, ensuring that they remain a key player in the global slurry pump landscape.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025