Feb . 13, 2025 00:12 Back to list

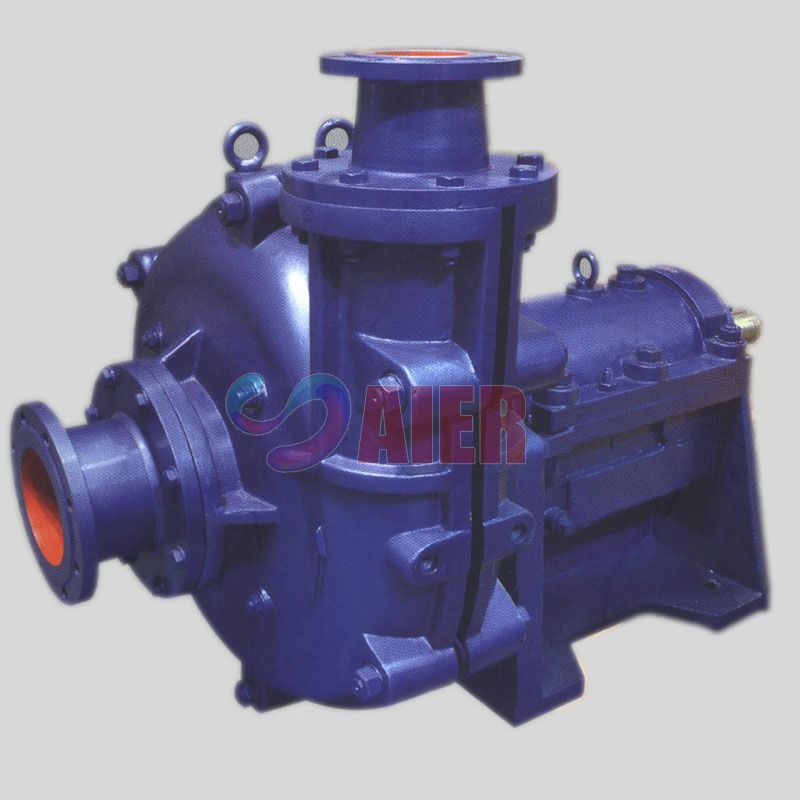

close impeller type slurry pump factory

When considering the optimal solution for managing robust slurry applications, few components prove as pivotal as the slurry pump casing. As the protective shell and structural backbone of the pump, the casing plays an integral role in dictating performance, reliability, and service life. Boasting decades of combined experience within the industry, experts emphasize the importance of selecting the ideal slurry pump casing to ensure efficiency, minimize downtime, and ultimately, protect valuable assets within industrial operations.

Trustworthiness in a slurry pump company is built through a track record of dependable products and exemplary customer service. Successful companies provide expansive support, ranging from assistance in selecting the appropriate pump materials based on the specific chemical and physical properties of the slurry, to comprehensive post-purchase services including installation support, maintenance advice, and rapid supply of spare parts. Such commitment to customer service not only extends the life of the pump but also fosters a sense of assurance among clients. Furthermore, real-world experience has repeatedly shown that the correct installation of a slurry pump casing can substantially reduce wear and tear. Proper alignment and securing of the casing prevent undue stress on the structure, a common cause of premature casing failure. Cross-industry studies underscore the importance of pairing a high-quality casing with a competent installation team to maximize operational uptime and efficiency. Despite these advancements, the future of slurry pump casing holds exciting possibilities. Emerging technologies such as additive manufacturing offer the potential for custom, lightweight casing solutions, even in small production runs. Advanced wear coatings and enhancements in material science promise greater longevity and efficiency, opening up opportunities for the deployment of slurry pumps in even more demanding scenarios. In conclusion, the slurry pump casing is an essential component in ensuring seamless slurry management in diverse applications. By focusing on expertise during design, leveraging authoritative manufacturing processes, and building trustworthy client relationships, manufacturers can continue to push the boundaries of efficiency and durability in the world of slurry pumps. As technology evolves, those who remain at the forefront of casing innovation will be best positioned to meet the growing demands of industries around the globe, reflecting a true commitment to excellence and advancement in this critical field.

Trustworthiness in a slurry pump company is built through a track record of dependable products and exemplary customer service. Successful companies provide expansive support, ranging from assistance in selecting the appropriate pump materials based on the specific chemical and physical properties of the slurry, to comprehensive post-purchase services including installation support, maintenance advice, and rapid supply of spare parts. Such commitment to customer service not only extends the life of the pump but also fosters a sense of assurance among clients. Furthermore, real-world experience has repeatedly shown that the correct installation of a slurry pump casing can substantially reduce wear and tear. Proper alignment and securing of the casing prevent undue stress on the structure, a common cause of premature casing failure. Cross-industry studies underscore the importance of pairing a high-quality casing with a competent installation team to maximize operational uptime and efficiency. Despite these advancements, the future of slurry pump casing holds exciting possibilities. Emerging technologies such as additive manufacturing offer the potential for custom, lightweight casing solutions, even in small production runs. Advanced wear coatings and enhancements in material science promise greater longevity and efficiency, opening up opportunities for the deployment of slurry pumps in even more demanding scenarios. In conclusion, the slurry pump casing is an essential component in ensuring seamless slurry management in diverse applications. By focusing on expertise during design, leveraging authoritative manufacturing processes, and building trustworthy client relationships, manufacturers can continue to push the boundaries of efficiency and durability in the world of slurry pumps. As technology evolves, those who remain at the forefront of casing innovation will be best positioned to meet the growing demands of industries around the globe, reflecting a true commitment to excellence and advancement in this critical field.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025