febr . 10, 2025 19:36 Back to list

E4110A05 high chrome volute liner

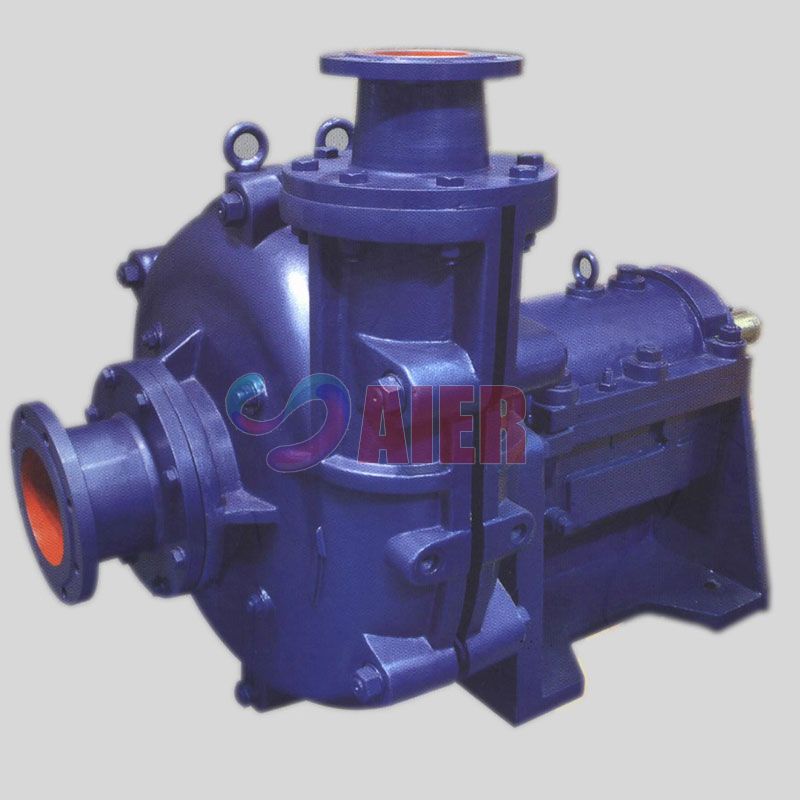

In the realm of industrial equipment, the durability and efficiency of a slurry pump's components are paramount. One such critical component, the slurry pump cover plate liner, plays a significant role in ensuring the longevity and optimal performance of the pump system. With years of experience in the field of slurry pump manufacturing and maintenance, I have witnessed firsthand the advancements and innovations in cover plate liner materials and design that have revolutionized the industry.

Authoritativeness in the slurry pump domain means understanding and adhering to global standards and certifications essential for quality assurance. Manufacturers and suppliers of slurry pump cover plate liners must comply with international guidelines, such as ISO and ASME standards, which dictate the quality and safety benchmarks for these critical components. Working with certified suppliers guarantees that users receive liners designed to withstand the rigorous demands of their operations. Trustworthiness in this industry comes from transparency and a track record of successful applications in diverse operational settings. Testimonials from clients who have experienced reduced downtime and maintenance costs attest to the reliability of high-quality cover plate liners. Case studies showcasing long-term use in harsh conditions further cement the credibility of suppliers and manufacturers committed to developing durable liners. Choosing the right slurry pump cover plate liner involves a comprehensive understanding of the specific technical requirements and operational challenges posed by the intended application. Collaboration with engineers and specialists who possess a deep understanding of pump dynamics and material science can facilitate informed decision-making. This collaborative approach ensures that the chosen liner significantly extends the pump's service life while optimizing performance, ultimately leading to cost savings and increased productivity. In conclusion, the evolution of slurry pump cover plate liners illustrates the intersection of innovation, expertise, and quality assurance. As industries continue to demand robust, efficient solutions for handling challenging fluids, the importance of selecting the right liner material and design becomes increasingly apparent. Through continuous research and collaboration among engineers, manufacturers, and end-users, the slurry pump industry is poised to meet the challenges of tomorrow with resilience and reliability.

Authoritativeness in the slurry pump domain means understanding and adhering to global standards and certifications essential for quality assurance. Manufacturers and suppliers of slurry pump cover plate liners must comply with international guidelines, such as ISO and ASME standards, which dictate the quality and safety benchmarks for these critical components. Working with certified suppliers guarantees that users receive liners designed to withstand the rigorous demands of their operations. Trustworthiness in this industry comes from transparency and a track record of successful applications in diverse operational settings. Testimonials from clients who have experienced reduced downtime and maintenance costs attest to the reliability of high-quality cover plate liners. Case studies showcasing long-term use in harsh conditions further cement the credibility of suppliers and manufacturers committed to developing durable liners. Choosing the right slurry pump cover plate liner involves a comprehensive understanding of the specific technical requirements and operational challenges posed by the intended application. Collaboration with engineers and specialists who possess a deep understanding of pump dynamics and material science can facilitate informed decision-making. This collaborative approach ensures that the chosen liner significantly extends the pump's service life while optimizing performance, ultimately leading to cost savings and increased productivity. In conclusion, the evolution of slurry pump cover plate liners illustrates the intersection of innovation, expertise, and quality assurance. As industries continue to demand robust, efficient solutions for handling challenging fluids, the importance of selecting the right liner material and design becomes increasingly apparent. Through continuous research and collaboration among engineers, manufacturers, and end-users, the slurry pump industry is poised to meet the challenges of tomorrow with resilience and reliability.

Latest news

-

Wholesale Slurry Pump Rubber Impeller for Mining & Industry

NewsJul.27,2025

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025