Jan . 13, 2025 14:20 Back to list

OEM Castings

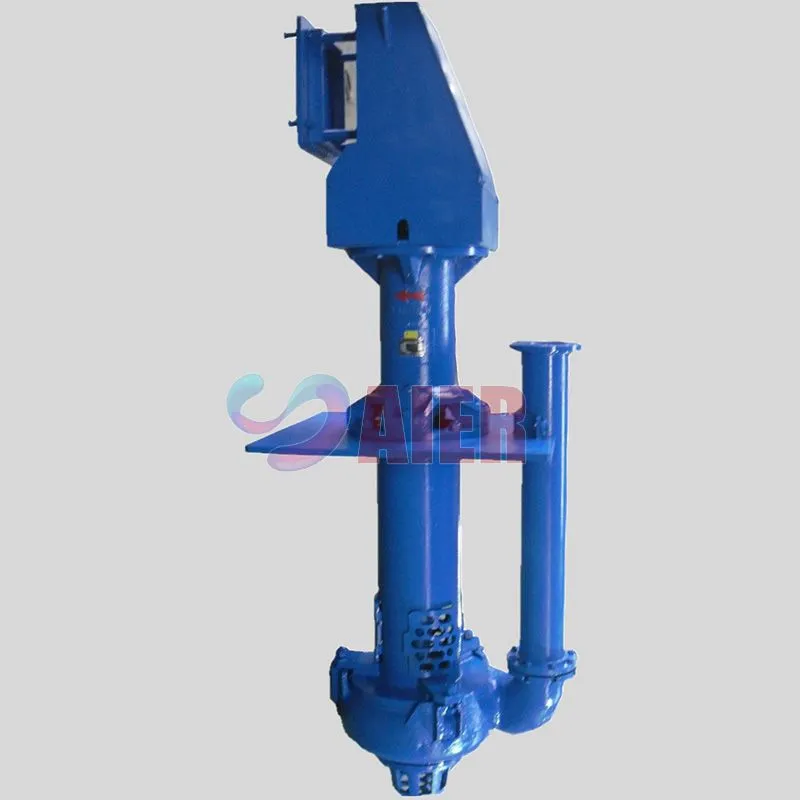

Selecting the perfect heavy duty submersible slurry pump is essential for industries dealing with abrasive fluids in challenging environments. These pumps, designed to handle fluids laden with abrasive particles, provide indispensable support in mining, construction, and wastewater industries. Through first-hand experience and professional expertise, we delve into what makes them the champions of slurry solutions, encompassing design aspects, operational efficiency, and maintenance protocols.

Authoritative bodies and standard certifications further bolster the credibility of heavy duty submersible slurry pumps. Compliance with ISO and ANSI standards offers assurance regarding their reliability and performance capacity. Besides, manufacturers often have dedicated R&D facilities to continually advance pump technology, ensuring they meet evolving industry standards and operational needs. Securing trustworthiness, many companies offer comprehensive pre-sales and post-sales support, providing detailed consultations to assist in selecting the right pump configuration for specific applications. Long-term maintenance warranties and access to an extensive service network form part of this trustworthy relationship, ensuring users can operate with confidence in demanding environments. In conclusion, the heavy duty submersible slurry pump stands as a cornerstone of contemporary slurry handling. It combines the resilience needed to withstand harsh conditions with the technical precision required for optimal performance. For industries committed to maintaining efficiency and reliability in their fluid management systems, investing in a quality slurry pump is not just advantageous, but essential. By choosing reputable brands and leveraging technological advancements, industries can ensure their operations remain seamless and resilient against the challenges presented by abrasive and dense slurries. In an arena where expertise and trust are paramount, these pumps continue to prove their worth.

Authoritative bodies and standard certifications further bolster the credibility of heavy duty submersible slurry pumps. Compliance with ISO and ANSI standards offers assurance regarding their reliability and performance capacity. Besides, manufacturers often have dedicated R&D facilities to continually advance pump technology, ensuring they meet evolving industry standards and operational needs. Securing trustworthiness, many companies offer comprehensive pre-sales and post-sales support, providing detailed consultations to assist in selecting the right pump configuration for specific applications. Long-term maintenance warranties and access to an extensive service network form part of this trustworthy relationship, ensuring users can operate with confidence in demanding environments. In conclusion, the heavy duty submersible slurry pump stands as a cornerstone of contemporary slurry handling. It combines the resilience needed to withstand harsh conditions with the technical precision required for optimal performance. For industries committed to maintaining efficiency and reliability in their fluid management systems, investing in a quality slurry pump is not just advantageous, but essential. By choosing reputable brands and leveraging technological advancements, industries can ensure their operations remain seamless and resilient against the challenges presented by abrasive and dense slurries. In an arena where expertise and trust are paramount, these pumps continue to prove their worth.

Latest news

-

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

NewsAug.04,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025