Dec . 19, 2024 23:31 Back to list

high quality filter press slurry pump

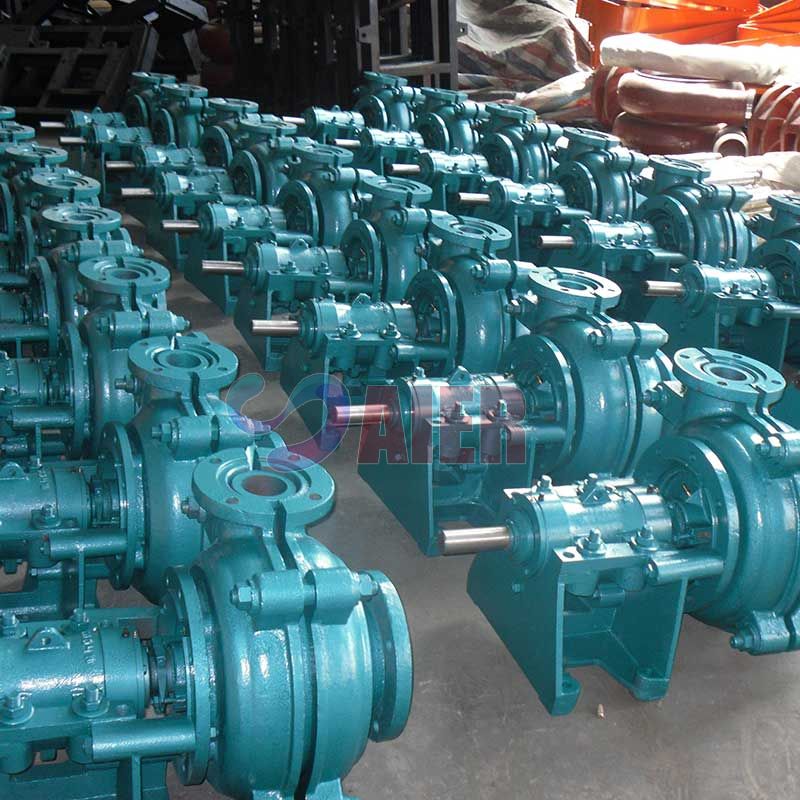

High-Quality Filter Press Slurry Pumps Essential Equipment for Efficient Industrial Processes

In various industrial sectors, the effective handling of slurry—an aqueous mixture of solid particles and liquid—is crucial. Slurry can be generated in processes such as mineral processing, wastewater treatment, and food production. To ensure efficient operation and management of these slurries, high-quality filter press slurry pumps are indispensable. This article discusses the importance of these pumps, their functionality, and the key features that define their performance.

Understanding Slurry Pumps

Slurry pumps are designed specifically for transporting mixtures of solids and liquids, making them suitable for managing slurry in various applications. Unlike conventional pumps, which are primarily used for clean liquids, slurry pumps must handle abrasive materials without suffering wear and damage. High-quality slurry pumps are built to endure the harsh conditions typically associated with slurry transport, making them a vital component in any industry that deals with these mixtures.

The Role of Filter Presses in Slurry Management

Filter presses are used to separate solids from liquids in slurry, enhancing the efficiency of the overall processing system. After the filtration process, the remaining slurry needs to be managed properly, and this is where high-quality filter press slurry pumps come into play. These pumps effectively transfer the separated slurry to storage or further processing, ensuring minimal loss of solids and maximum recovery of valuable materials.

Key Features of High-Quality Slurry Pumps

1. Robust Construction High-quality slurry pumps are constructed from durable materials capable of withstanding abrasive and corrosive elements. Common materials include high-chrome alloys and rubber-lined casings that increase longevity while minimizing maintenance requirements.

2. Efficiency and Performance Efficiency is a paramount consideration when selecting a slurry pump. A high-quality pump will deliver superior performance by maintaining optimal flow rates while handling varying consistencies of slurry. The design of the impeller and the pump casing is critical in ensuring efficient energy use and minimizing operational costs.

high quality filter press slurry pump

3. Self-Priming Capabilities One of the challenges associated with slurry handling is the risk of cavitation, which can lead to pump failure. High-quality slurry pumps often feature self-priming capabilities, eliminating the need for manual priming and ensuring reliable operation in a range of conditions.

4. Versatile Operation Processing environments can vary widely, and a high-quality filter press slurry pump should be adaptable to different types of slurries, including thick, viscous, or solid-heavy mixtures. The versatility of these pumps allows for seamless integration into existing systems, enhancing workflow efficiency.

5. Ease of Maintenance Maintenance plays a crucial role in the longevity and reliability of any industrial equipment. High-quality slurry pumps are designed for easy access to components that require routine inspection and repair. This reduces downtime and keeps production schedules on track.

6. Energy Efficiency In today's environmentally conscious world, energy efficiency is an important factor. High-quality slurry pumps are engineered to minimize energy consumption while maximizing output, contributing to lower operational costs and reduced environmental impact.

Applications of Filter Press Slurry Pumps

The applications for high-quality filter press slurry pumps span numerous industries. In mining, they play a vital role in transporting tailings, while in construction and civil engineering, they are used for managing sediment in water treatment processes. The food industry also benefits from these pumps in the efficient handling of food waste. Each of these applications demands reliability, efficiency, and durability, highlighting the importance of investing in quality pump systems.

Conclusion

High-quality filter press slurry pumps are crucial for efficient slurry management in various industrial applications. Their robust construction, efficiency, versatility, and ease of maintenance make them essential components in processes that involve the movement and treatment of slurry. As industries continue to evolve and face increasing demands for efficiency and sustainability, the role of these pumps will undoubtedly become more significant. Investing in high-quality slurry pumps not only enhances operational efficiency but also contributes to safer and more sustainable industrial practices.

-

High-Quality Sand Suction Dredge Pump Factories Durable & Efficient

NewsMay.22,2025

-

High-Quality Interchangeable Slurry Pump Spare Parts Supplier China

NewsMay.22,2025

-

China Gravel Dredge Pump - Heavy-Duty Slurry & Sand Dredging

NewsMay.22,2025

-

Durable Centrifugal Wastewater Pumps China Abrasives Pump Suppliers

NewsMay.21,2025

-

High-Quality Horizontal Centrifugal Slurry Pump China Factory & Supplier

NewsMay.21,2025

-

China Slurry Pump Rubber Parts - Durable & Custom Solutions

NewsMay.20,2025