Back to list

How To Use Slurry Pumps Efficiently?

>Slurry pumps are dominantly popular for their robust construction and the ability to work under strenuous situations. The process industry mainly works with centrifugal pumps and the ratio between slurry and other pumps for liquid is nearly 5:95. But if you take a look at the operating costs for these pumps, the ratio turns nearly upside down with 80:20 which explains the wide popularity of slurry pumps.

Introduction To Slurry Pumps

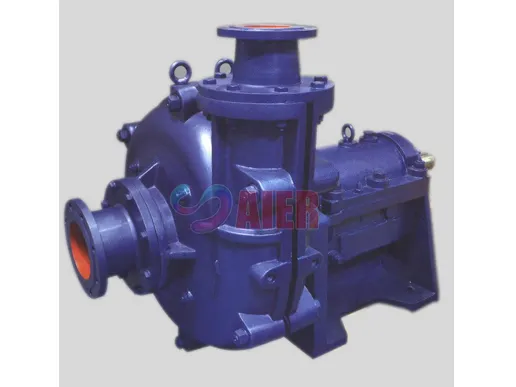

A slurry pump is a unique type of a pump which is used to handle slurry. Contrary to water pumps, slurry pumps are heavy-duty constructed and undergo more wear and tear. Technically, slurry pumps are a heavy and robust version of centrifugal pumps that have the capability of handling abrasive and tough tasks. As compared to other pumps, slurry pumps have a much simpler design and construction. Despite an elementary design, slurry pumps offer high endurance and strength under harsh conditions. These forms of pumps play a crucial role in various industries. They are fundamental to all wet processes.

What is Slurry?

In principle, it is possible to hydro transport any solid. Particle size and shape, however, may act as limiting factors based on whether they can pass through pump tubes without creating blockages. Under the broad category of slurry, there are 4 major classifications that can help you identify a suitable type of slurry pump that fulfills your demands and meets your business requirements.

Slurry Pump

Type 1:

Mildly Abrasive

Type 2:

Slightly Abrasive

Type 3:

Significantly More Abrasive

Type 4:

Highly Abrasive

If you want to move highly abrasive type 4 slurries, the ideal choice would be Oil sand pumps. The ability to handle high volumes of slurry and the enhanced withstanding capability is what gives an edge to slurry pumps. They are specifically designed to hydrotransport large-particle solids and ensure better wear performance in rough conditions.

Four centrifugal slurry pump types

Although centrifugal slurry pumps are widely known for their uses in oil sands, many of them have additional uses as well.

Hydrotransport

— Hydrotransport pumps are used for plenty of applications because moving slurry is hydrotransport. The ideal way to use these slurry pumps is with water-based solutions. They are mostly used in industries which require dredging.

Slurry Pump

Tailings Transfer

— Tailings Transfer pumps are the perfect type of pumps to transport tailings or finer abrasive materials resulting from hard rock mining, such as fragments of mud and ore, as well as related chemicals used in the mining process.

Cyclone Feed

— Cyclone feed pumps, like tailings pumps, are also used in hard rock mining and are comparable to hydrotransport pumps as they are also used in dredging operations. These forms of pumps are used at all stages of scalping and separating solids by particle size.

Flotation Froth

— A slurry pump can also be used for transporting froth, however the air trapped in the froth can negatively impact the pump’s performance. Even though slurry pumps are built with a sturdy construction, the air contained in the froth can damage the pump and shorten its life. But, with proper preventive measures of centrifugal pumps, you can reduce the wear and tear of the pump.

If you want to know more about how to select the best centrifugal pump for your business needs or need an extra hand with the maintenance of your pumps, we are here to help you.

>

-

New Developments in Rubber Slurry Pump Factory

NewsJun.30,2025

-

Industrial Applications of Submersible Water Pumps

NewsJun.30,2025

-

How Quality Ceramic Slurry Pump Enhances Efficiency

NewsJun.30,2025

-

Heat Treatment of Metal Slurry Pump Parts

NewsJun.30,2025

-

FGD Pump Installation Best Practices

NewsJun.30,2025

-

Applications of Vertical Slurry Pump in Mining

NewsJun.30,2025