Nov . 24, 2024 06:00 Back to list

water pump factories

The Evolution of Water Pump Factories

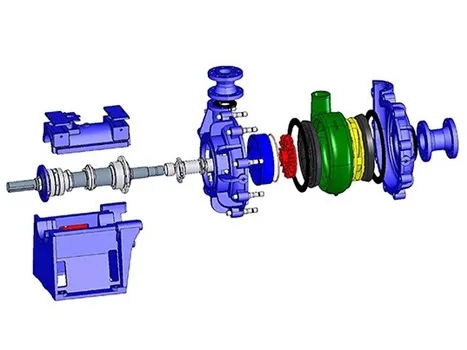

Water pumps are essential devices that facilitate the movement and distribution of water in various applications, ranging from agricultural irrigation to residential plumbing systems. The evolution of water pump factories has significantly influenced the efficiency, technology, and accessibility of these crucial machines.

Historically, the need for water management has existed since ancient civilizations. Early water-pumping devices like the Archimedes screw or the water wheel showcased mankind's ingenuity in managing water resources. However, it was during the Industrial Revolution that the first modern water pump factories emerged, marking a significant transition in their production processes and technologies. Factories began to employ steam power to manufacture pumps, greatly increasing their output and efficiency.

In the 20th century, advancements in materials and engineering further transformed water pump production. Factories began utilizing durable materials such as stainless steel and high-quality plastics, which improved pump longevity and reliability. The introduction of electric motors led to the creation of submersible pumps that could operate underwater, revolutionizing the way water was accessed, stored, and transported. This was particularly beneficial for agricultural practices, where efficient irrigation systems became vital as populations grew and urbanization expanded.

Today, water pump factories around the globe incorporate sophisticated automation and robotics in their manufacturing processes. With the rise of Industry 4.0, many factories are integrating smart technologies and IoT devices into their production lines. This not only enhances the efficiency of the assembly line but also improves quality control and reduces manufacturing costs. Factories equipped with predictive maintenance systems can identify issues before they lead to breakdowns, ensuring a continuous supply of pumps to meet the demands of various industries.

water pump factories

Moreover, sustainability has become an essential consideration for modern water pump factories. The need for eco-friendly manufacturing practices is paramount in today's climate-conscious world. Many manufacturers are now focusing on the production of energy-efficient pumps that consume less power and have a smaller environmental footprint. By leveraging renewable energy sources and implementing recycling programs, factories are taking significant steps toward reducing their overall impact on the environment.

The global market for water pumps continues to expand, driven by urbanization, population growth, and increasing water scarcity issues. As emerging economies develop their infrastructure, the demand for efficient water management solutions is projected to rise. This presents a significant opportunity for water pump factories to innovate and adapt their products to meet the changing needs of consumers.

Furthermore, technological advancements such as 3D printing are beginning to reshape traditional manufacturing methods. Water pump parts can now be produced on-demand, reducing lead times and inventory costs. This adaptability allows factories to respond more swiftly to market changes, ensuring that they remain competitive.

In conclusion, water pump factories are at the forefront of technological innovation and sustainable practices in water management. Their evolution from simple mechanical devices to complex, energy-efficient machines underscores the importance of water pumps in our daily lives. As the challenges of water scarcity and environmental sustainability continue to grow, the role of water pump factories will be crucial in developing solutions that ensure the efficient use of this vital resource for generations to come.

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025

-

Premium Studs for Cover & Frame Plates | Corrosion-Resistant

NewsJul.20,2025

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025