Nov . 02, 2024 09:43 Back to list

warman slurry pump parts manufacturers

Understanding Warman Slurry Pump Parts Manufacturers

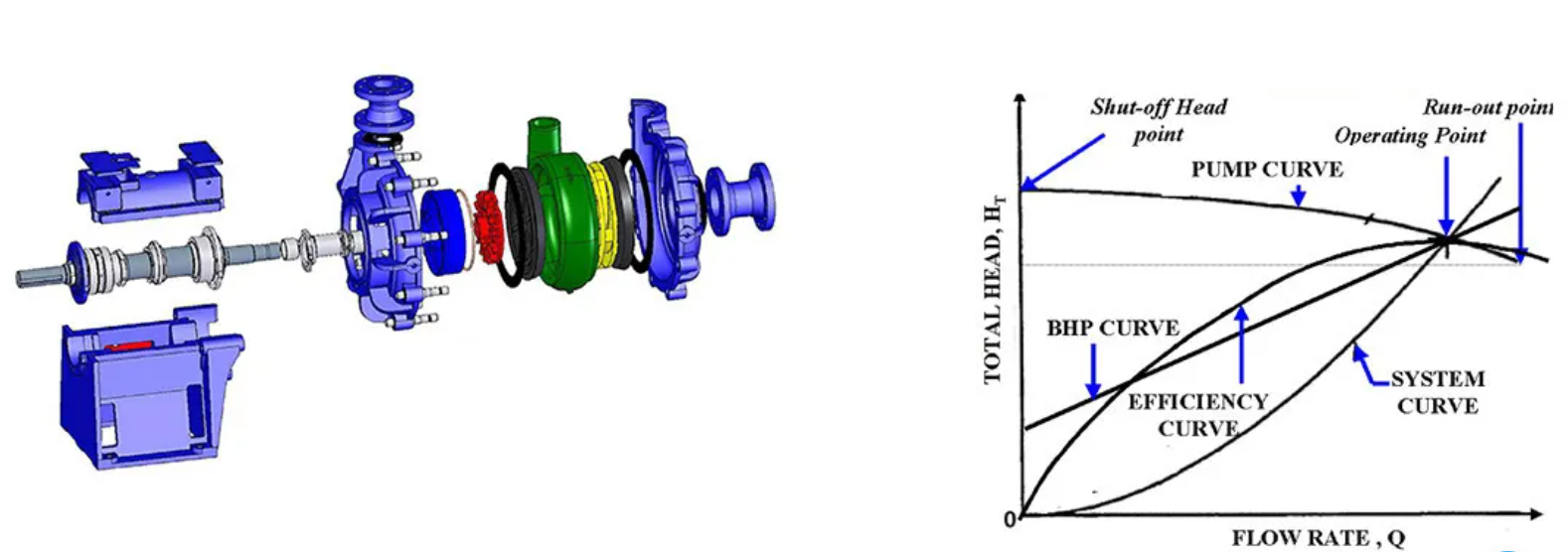

Warman slurry pumps are well-known in various industries for their ability to handle abrasive and corrosive slurries, providing reliable performance in challenging conditions. However, like any complex machinery, the efficiency and longevity of Warman slurry pumps greatly depend on the quality of their parts. This is where the role of Warman slurry pump parts manufacturers comes into play.

Warman slurry pumps are used across a multitude of sectors, including mining, mineral processing, and wastewater treatment. These applications require pumps that can manage thick, viscous fluids laden with solids, which inevitably leads to wear and tear on the pump components. As such, the demand for high-quality replacement parts is critical to the continued operation of these pumps.

Manufacturers of Warman slurry pump parts must adhere to stringent standards to ensure that their products can withstand the harsh environments in which these pumps operate. Key components such as impellers, volutes, liners, and shafts are crafted to exact specifications. High-grade materials are often utilized, such as high chromium alloys, to enhance durability and resist abrasion.

One notable advantage of reliable parts manufacturers is their ability to provide tailored solutions that meet specific operational demands. Different applications may require unique modifications or enhancements, such as increased thickness for added wear resistance or specialized coatings to combat corrosion. Trusted manufacturers often work closely with end-users to customize parts for performance optimization.

warman slurry pump parts manufacturers

In the competitive landscape of pump parts manufacturing, companies often distinguish themselves through their service offerings. Providing exceptional customer service, technical support, and speedy delivery of parts are crucial factors for businesses looking to minimize downtime. Some manufacturers may also offer refurbishment services for worn-out components, extending the lifecycle of the equipment and providing cost-effective solutions.

Globalization has also influenced the market for Warman slurry pump parts. With manufacturers spread across various regions, businesses can source components from different suppliers, sometimes benefitting from competitive pricing. However, it is essential to vet these suppliers for quality assurance. Reputable manufacturers typically adhere to international standards and possess certifications that validate the quality of their offerings.

Innovation is another key trend in the production of slurry pump parts. Advances in material science and technology have led to the development of new materials and designs that further enhance the performance and durability of pump components. This continual evolution challenges manufacturers to stay at the forefront of technology to meet the changing demands of the industry.

In conclusion, Warman slurry pump parts manufacturers play a pivotal role in maintaining the reliability and efficiency of slurry pump systems. By focusing on high-quality materials, customized manufacturing, exceptional service, and innovative advancements, these manufacturers ensure that industries relying on such pumps can achieve operational efficiency. Investing in quality components not only prolongs the life of slurry pumps but also enhances overall productivity, making it a critical consideration for any operation that utilizes Warman slurry pumps.

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025