Nov . 08, 2024 11:40 Back to list

Efficient Froth Centrifugal Slurry Pump Manufacturing Facilities and Their Innovations

The Role and Importance of Froth Centrifugal Slurry Pumps in Industrial Applications

Froth centrifugal slurry pumps are industrial machines designed to transport mixtures of solid particles, such as ore, with liquids, primarily water. These pumps play a crucial role in various sectors, including mining, mineral processing, and waste management. Their ability to handle frothy slurries—mixtures where bubbles are dispersed throughout the liquid—makes them indispensable in operations that demand high efficiency and reliability.

Understanding Froth and Its Challenges

Frothy slurries usually occur in processes like flotation, where air is introduced into a liquid containing solid particles. This results in the formation of bubbles that bind to the particles, causing them to rise to the surface. While this process is essential in the mining industry, dealing with frothy slurries poses significant challenges. The presence of air bubbles can lead to issues such as cavitation, reduced efficiency, and increased wear on pump components. Therefore, selecting the right pump technology is critical for effective slurry transport.

Features of Froth Centrifugal Slurry Pumps

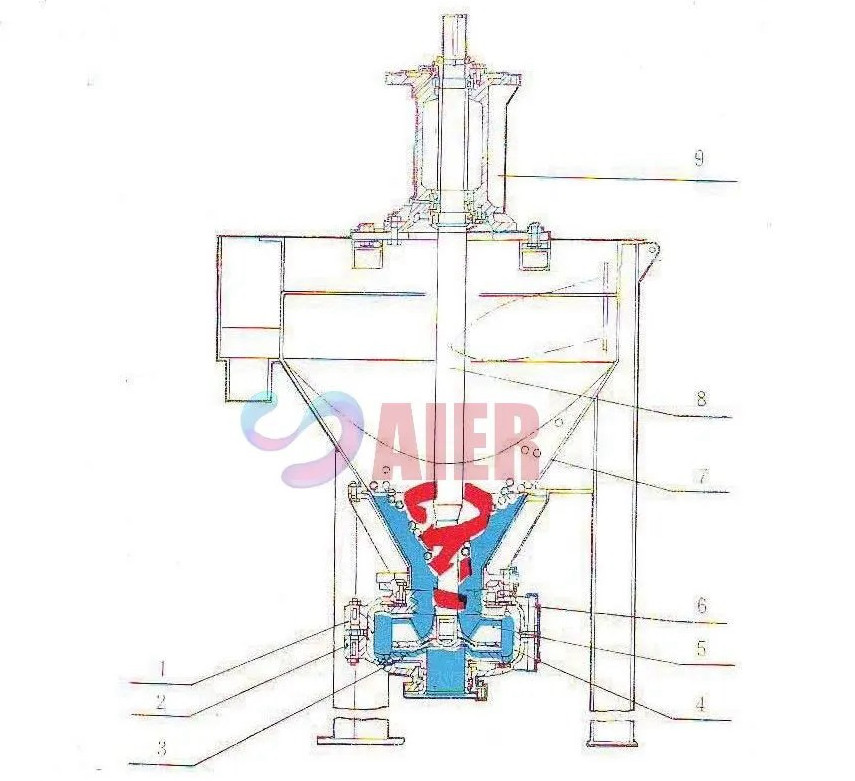

Froth centrifugal slurry pumps are designed specifically to address the challenges posed by frothy mixtures. These pumps are typically engineered with a robust construction to withstand abrasive materials and harsh operating conditions. Key features include

1. Impeller Design The impellers are specifically shaped to facilitate the movement of slurries while minimizing the impact of cavitation. This design helps maintain a consistent flow even when air bubbles are present.

2. Pump Casing The casing is often made from high-wear-resistant materials, which extends the lifespan of the pump and enhances its operational efficiency.

3. Variable Speed Drives Many modern froth centrifugal pumps are coupled with variable speed drives that allow for adjustments in flow rates based on process demands. This feature improves energy efficiency and enables precise control over slurry transport.

froth centrifugal slurry pump factories

4. Built-in Air Separation Some advanced designs incorporate mechanisms to separate air from the slurry before it enters the pump, ensuring that the pump operates under optimal conditions.

Applications in Industry

Froth centrifugal slurry pumps are extensively utilized in sectors where slurry processing is vital. In mining, these pumps are used to transport mineral-rich slurries from flotation cells to further processing stages. In mineral processing plants, they facilitate the movement of tailings, ensuring that valuable resources are not wasted.

Moreover, in wastewater treatment facilities, these pumps help in managing sludge by effectively moving solids without disrupting the overall process. Their versatility makes them suitable for various applications, demonstrating their importance across multiple industries.

Benefits of Using Froth Centrifugal Slurry Pumps

The use of froth centrifugal slurry pumps offers several benefits. They enhance operational efficiency by providing reliable transport of slurries, reducing downtime and maintenance costs. Their ability to handle frothy mixtures effectively contributes to optimizing production processes in industries where margins can be tight.

Additionally, these pumps are designed to be energy-efficient, which can lead to substantial cost savings over time. Reducing energy consumption is not only beneficial for the bottom line but also aligns with the growing emphasis on sustainable industrial practices.

Conclusion

In conclusion, froth centrifugal slurry pumps are integral to the smooth operation of industries dealing with frothy slurries. Their specialized design and capabilities make them essential for achieving high efficiency, reliability, and sustainability in various applications. As technology continues to advance, these pumps are likely to evolve further, meeting the ever-increasing demands of modern industrial processes. Understanding their role and features is essential for anyone involved in industries reliant on the effective transport of slurries, ensuring that operations run smoothly and economically.

-

Durable Centrifugal Wastewater Pumps China Abrasives Pump Suppliers

NewsMay.21,2025

-

High-Quality Horizontal Centrifugal Slurry Pump China Factory & Supplier

NewsMay.21,2025

-

China Slurry Pump Rubber Parts - Durable & Custom Solutions

NewsMay.20,2025

-

Heavy Duty Vertical Froth Pumps - China Factories & High-Quality Suppliers

NewsMay.20,2025

-

High-Quality Excavator Dredge Pump Suppliers China Manufacturers

NewsMay.19,2025

-

China Slurry Pump Rubber Parts - Durable & Custom Solutions

NewsMay.19,2025