Dec . 11, 2024 05:44 Back to list

High Efficiency Dual Casing Slurry Pump for Optimal Performance and Durability

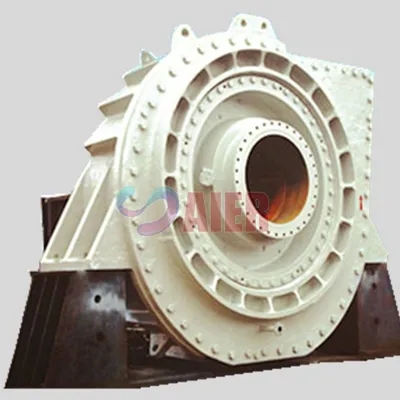

High-Quality Twin Casing Slurry Pump An Overview

In various industrial applications, the need to transport abrasive and viscous materials efficiently is crucial. This is where high-quality twin casing slurry pumps come into play. Designed specifically to handle slurries, these pumps offer exceptional durability, efficiency, and reliability, ensuring that industries can maintain production without facing significant downtime due to equipment failure.

What is a Twin Casing Slurry Pump?

A twin casing slurry pump features two casings, which allows it to handle higher pressures and larger volumes of slurry compared to standard single casing pumps. The design assists in maintaining a steady flow of slurries, which often consist of a mixture of liquids and solid particles, making the pump suitable for various applications, including mining, dredging, and mineral processing.

Key Features

1. Robust Construction High-quality twin casing slurry pumps are constructed from wear-resistant materials, such as high chromium alloy or rubber-lined casings. This durability extends the life of the pump, reducing replacement and maintenance costs.

2. Efficient Performance These pumps are designed for high efficiency, which minimizes energy consumption while maximizing output. Their hydraulic design optimizes the flow of slurries, enabling them to handle viscous liquids and solids without excessive wear on the components.

3. Versatile Applications Twin casing slurry pumps can easily manage a range of slurry types, whether they include sand, gravel, coal, or other abrasive materials. This versatility makes them an ideal choice for industries such as mining, wastewater treatment, and construction.

4. Advanced Seal Systems To prevent leaks and ensure longevity, high-quality pumps are equipped with advanced sealing technology. Mechanical seals or packed seals are commonly used to protect the internal components from abrasive slurries and extend the operational lifespan of the pump.

5. Ease of Maintenance The design of twin casing pumps often allows for easy disassembly for maintenance and repairs. This user-friendly aspect reduces downtime and increases operational efficiency, supporting a smoother flow in the production process.

Advantages of Using High-Quality Twin Casing Slurry Pumps

high quality twin casing slurry pump

- Reduced Operational Costs While the initial investment may be higher than standard pumps, the reduced wear and tear and lower maintenance needs translate into significant cost savings over time.

- Enhanced Reliability With their robust construction and advanced design features, these pumps provide unparalleled reliability, ensuring continuous operation even in the harshest conditions.

- Improved Flow Rates High-quality twin casing slurry pumps deliver improved flow rates, achieving efficient transportation of slurries across long distances.

- Environmentally Friendly Modern pumps are designed with efficiency in mind, contributing to lower energy consumption and reduced carbon footprints for environmentally conscious enterprises.

Applications of Twin Casing Slurry Pumps

1. Mining Operations In the mining industry, these pumps are essential for transporting ore and waste slurries to and from processing plants. Their ability to handle high solids content makes them indispensable in mineral extraction operations.

2. Dredging Dredging projects require pumps that can handle large volumes of water mixed with sediment. Twin casing slurry pumps are perfect for this task, efficiently moving materials from dredging vessels to disposal sites.

3. Wastewater Treatment In municipal and industrial wastewater treatment plants, these pumps play a crucial role in transporting sludge and other by-products of the treatment process.

4. Construction In construction projects, especially those dealing with ground remediation or site preparation, twin casing slurry pumps effectively manage the removal of slurries created by drilling and excavation activities.

Conclusion

In conclusion, high-quality twin casing slurry pumps are indispensable tools across various industries, providing efficiency, reliability, and versatility in handling challenging materials. Their innovative design caters to the needs of businesses aiming for cost-effective and sustainable operational practices. Investing in advanced slurry pumping solutions not only enhances productivity but also contributes to the long-term success of industrial operations. With continuous advancements in technology and materials, twin casing slurry pumps will undoubtedly evolve, further solidifying their role as vital components in industrial applications.

-

High-Quality CH Warman Slurry Pump Factories Heavy Duty & Custom Solutions

NewsMay.28,2025

-

Wholesale Metal-Lined Slurry Pump Parts Durable & Corrosion-Resistant

NewsMay.28,2025

-

High-Efficiency Submerged Mining Vertical Slurry Pump Suppliers

NewsMay.28,2025

-

High-Efficiency & Durable Best Slurry Pumps Reliable Solutions

NewsMay.28,2025

-

China Self Priming Drainage Pump - Durable & High-Capacity Wholesale

NewsMay.28,2025

-

China Tailing Slurry Pump Supplier High-Efficiency & Durable Solutions

NewsMay.28,2025