નવેમ્બર . 18, 2024 20:05 Back to list

high quality wastewater grinder centrifugal pump manufacturers

High-Quality Wastewater Grinder and Centrifugal Pump Manufacturers

The global demand for effective wastewater management solutions has never been more critical. As industries continue to expand and urban populations rise, so does the volume of wastewater generated. To address this challenge, high-quality wastewater grinder and centrifugal pump manufacturers play a vital role. These manufacturers produce advanced equipment designed to tackle the complex characteristics of wastewater, ensuring efficient processing, reduced downtime, and minimal environmental impact.

Understanding Wastewater Grinders and Centrifugal Pumps

Wastewater grinders and centrifugal pumps are integral components of wastewater treatment facilities. Grinders are designed to reduce the size of solid waste materials, such as large tissues, plastic items, and food waste. By grinding these materials into smaller particles, grinders facilitate smoother processing and prevent clogs in pumps and pipes. The use of grinders is essential in protecting the downstream equipment, leading to longer service life and lower maintenance costs.

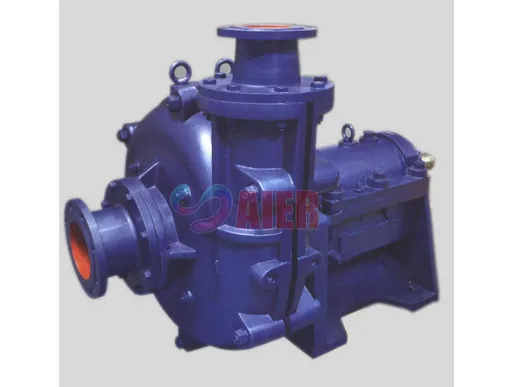

Centrifugal pumps, on the other hand, are used to move the processed wastewater through the treatment system. These pumps operate by converting rotational energy into hydrodynamic energy, efficiently transporting fluids over varying distances and elevations. The combination of reliable grinders and powerful centrifugal pumps allows for a seamless wastewater treatment process, resulting in fewer interruptions and greater efficiency.

Key Characteristics of High-Quality Manufacturers

When selecting a wastewater grinder or centrifugal pump manufacturer, it's crucial to consider several key attributes

. Here are some of the primary characteristics that define high-quality manufacturers in this sector1. Expertise and Experience Established manufacturers with extensive experience in wastewater management have a better understanding of the complexities associated with different types of wastewater. Their expertise often translates into superior design and functionality of their products.

2. Innovative Technology High-quality manufacturers invest in research and development to create innovative solutions. This includes incorporating advanced materials, automated controls, and energy-efficient designs to ensure longevity and performance of grinders and pumps.

high quality wastewater grinder centrifugal pump manufacturers

3. Comprehensive Testing Before reaching the market, equipment should undergo rigorous testing to meet operational standards. Quality manufacturers implement thorough testing protocols to simulate real-world conditions, ensuring that their products can withstand the challenges of wastewater environments.

4. Customization Options Different industries and facilities may have unique requirements. Reputable manufacturers offer customization options to tailor solutions that fit specific operational needs, which helps to optimize performance and resource management.

5. Warranty and Support A strong warranty and reliable after-sale support can significantly impact the total cost of ownership. Top manufacturers stand behind their products by providing comprehensive warranties and responsive customer support to address any operational issues that might arise.

6. Sustainability Practices As environmental concerns continue to rise, manufacturers are increasingly adopting sustainable practices. This includes producing energy-efficient equipment that minimizes resource consumption during operation and lowering the carbon footprint of wastewater treatment processes.

Making the Right Choice

Choosing the right wastewater grinder and centrifugal pump manufacturer can significantly influence the efficiency and reliability of a treatment facility. It is essential for facilities to conduct thorough research, examining different manufacturers' offerings, reputation, and customer feedback. Facility operators should evaluate not only the performance characteristics of the equipment but also the full scope of support throughout the product's lifecycle.

Additionally, collaborations with manufacturers that prioritize sustainability can lead to more environmentally friendly operations. Investing in high-quality equipment from reputable manufacturers ultimately leads to better performance, reduced maintenance costs, and improved compliance with environmental regulations.

Conclusion

High-quality wastewater grinder and centrifugal pump manufacturers are essential partners in the ongoing battle against wastewater management challenges. By choosing manufacturers that excel in innovation, testing, and support, facilities can ensure efficient processing of wastewater while minimizing environmental impact. As the industry continues to evolve, these manufacturers will play a critical role in shaping sustainable practices and driving advancements in wastewater treatment technology. Investing in top-tier equipment is not just about immediate performance; it is an investment in the future of water resource management.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025