ડીસેમ્બર . 21, 2024 04:46 Back to list

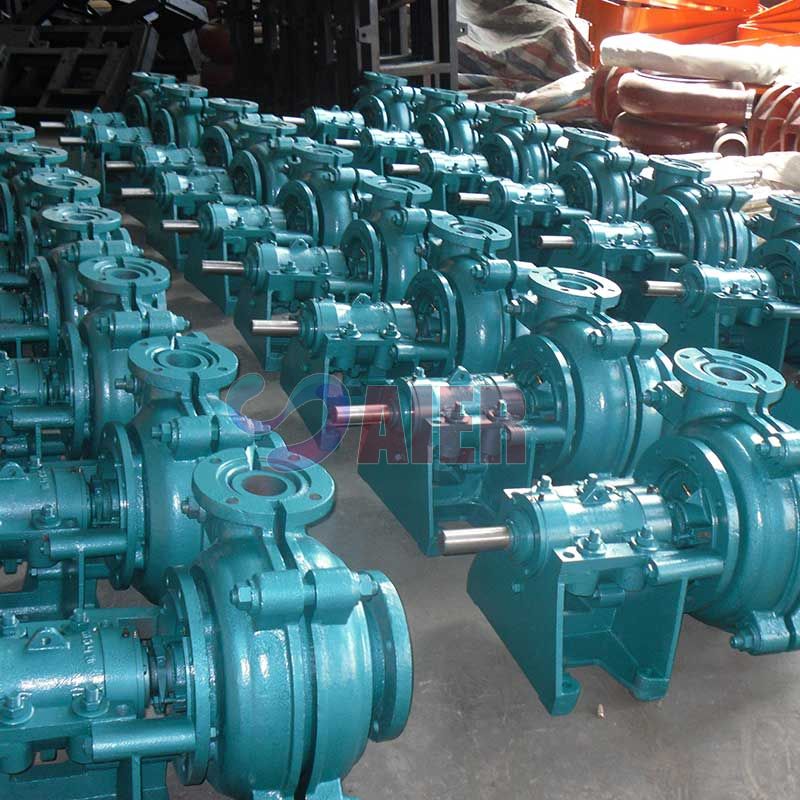

high quality high pressure pump for detergent slurry factory

High Quality High Pressure Pumps for Detergent Slurry Factories

In today's industrial landscape, the demand for efficient, reliable, and high-performance equipment is at an all-time high, especially in the manufacturing of detergents and other chemical products. One of the most critical components in detergent slurry factories is the high-pressure pump. These pumps play a pivotal role in the processing and transportation of viscous materials, ensuring that operations run smoothly and effectively.

Understanding High-Pressure Pumps

High-pressure pumps are specifically engineered to handle a variety of challenging substances, including detergent slurries. These slurries are often thick, requiring robust pumps that can maintain consistent pressure levels to transport the material without degradation. High-quality pumps are designed to withstand the harsh conditions of chemical processing, which includes exposure to corrosive substances, high-temperature environments, and the need for continuous operation.

Key Features of Quality High-Pressure Pumps

1. Durability and Reliability Quality high-pressure pumps are constructed from durable materials such as stainless steel or high-grade plastics that resist corrosion and wear. This durability extends the lifespan of the pump, reducing the need for frequent replacements and repairs.

2. High Efficiency A significant attribute of a high-quality pump is its efficiency. Efficient pumps consume less energy while delivering higher output, which not only reduces operational costs but also minimizes the environmental impact.

3. Pressure Control Advanced high-pressure pumps come equipped with pressure regulation features that allow for precise control over the flow rates and pressure, ensuring that the chemical processes can be maintained within spec without overburdening the equipment.

4. Versatility The best high-pressure pumps are adaptable and can handle a wide range of slurry viscosities, making them suitable for different detergent formulations. This versatility means less downtime when switching between products and a more streamlined production process.

5. Ease of Maintenance Maintenance is crucial for the longevity of any industrial pump. High-quality pumps are designed for easy access to components, allowing for quick inspections and repairs without extensive downtime.

Applications in Detergent Slurry Production

high quality high pressure pump for detergent slurry factory

In detergent slurry factories, high-pressure pumps are essential in various stages of the manufacturing process. They are used to

- Mix Ingredients High-pressure pumps facilitate the efficient mixing of powdered and liquid ingredients, ensuring a homogenous slurry is produced, which is vital for the quality of the final product.

- Transport Slurries Once the detergent slurry has been created, it needs to be transported to different stages of production, including storage tanks and filling stations. The high-pressure capability ensures that the viscous slurry can be moved efficiently across the production line.

- Inject Additives Often, additives need to be incorporated into the detergent at specific stages. High-pressure pumps allow for precise injection, enhancing the effectiveness of the detergent.

Choosing the Right High-Pressure Pump

When selecting a high-pressure pump for a detergent slurry factory, several considerations should be taken into account

- Flow Rate and Pressure Requirements Determine the specific flow rate and pressure requirements based on the factory’s production capacity.

- Material Compatibility Ensure that the materials used in the pump construction are compatible with the slurry being handled.

- Manufacturer Reputation Investing in pumps from reputable manufacturers often provides a guarantee of quality, support, and availability of spare parts.

Conclusion

High-quality high-pressure pumps are an integral part of detergent slurry manufacturing, maximizing efficiency, reliability, and product quality. By investing in the right pump, factories can enhance their production capabilities, reduce operational costs, and ensure they meet the increasing demand for effective cleaning products. As the detergent market continues to grow, the role of advanced pumping technology will become even more critical, reinforcing the need for factories to seek out high-quality, high-pressure pumping solutions.

-

High-Quality Sand Suction Dredge Pump Factories Durable & Efficient

NewsMay.22,2025

-

High-Quality Interchangeable Slurry Pump Spare Parts Supplier China

NewsMay.22,2025

-

China Gravel Dredge Pump - Heavy-Duty Slurry & Sand Dredging

NewsMay.22,2025

-

Durable Centrifugal Wastewater Pumps China Abrasives Pump Suppliers

NewsMay.21,2025

-

High-Quality Horizontal Centrifugal Slurry Pump China Factory & Supplier

NewsMay.21,2025

-

China Slurry Pump Rubber Parts - Durable & Custom Solutions

NewsMay.20,2025