Dec . 04, 2024 09:14 Back to list

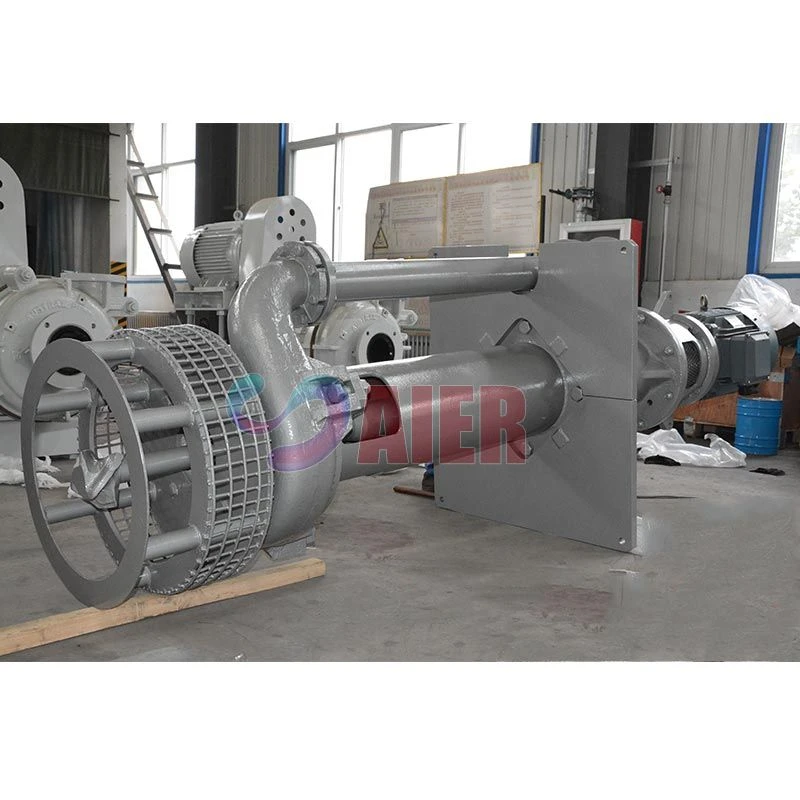

standard submersible slurry pump factory

Standard Submersible Slurry Pump Factory An Overview

In the ever-evolving industry of fluid handling, standard submersible slurry pumps play a crucial role in various applications, particularly in mining, construction, and wastewater management. These pumps are designed to handle abrasive and viscous materials, enabling efficient transportation of slurry, which is a mixture of liquids and solid particles. This article explores the features, applications, and advantages of submersible slurry pumps, along with insights into the workings of a standard submersible slurry pump factory.

Understanding Submersible Slurry Pumps

Submersible slurry pumps are unique engineering solutions that enable the pumping of slurry from deep underground or submerged environments. Unlike standard pumps, these devices are built to operate underwater and are often hermetically sealed to prevent leakage and protect the motor from water damage. This design not only improves durability but also enhances efficiency in handling challenging materials that can cause wear and tear in conventional pumps.

The construction of submersible slurry pumps often involves robust materials like cast iron or stainless steel, resistant to corrosion and erosion. These pumps feature high-flow and high-head designs, allowing them to transport slurry effectively over long distances. With various impeller designs, submersible slurry pumps can handle different types of slurry, making them versatile tools in industrial applications.

Applications of Submersible Slurry Pumps

1. Mining Industry In mining operations, submersible slurry pumps are used for dewatering applications, transporting slurries containing minerals, and managing tailings. Their ability to handle abrasive particles makes them essential in environments dealing with harsh conditions.

2. Construction Projects Construction sites often require effective water management to avoid flooding and ensure smooth operations. Submersible slurry pumps are deployed to remove excess water and slurry from excavation sites, helping in maintaining the integrity of structures.

3. Wastewater Management In municipal applications, these pumps facilitate the treatment of wastewater and sludge. Their capacity to handle thick liquids ensures efficient processing, which is vital for environmental safeguarding.

4. Dredging Operations Submersible slurry pumps are critical in dredging operations where sediment and water need to be removed from river beds, lakes, and harbors. They contribute to maintaining navigable waterways and ecological balance.

Advantages of Submersible Slurry Pumps

standard submersible slurry pump factory

The adoption of submersible slurry pumps offers numerous advantages

- Efficiency These pumps can operate at optimal efficiency since they are installed directly in the fluid they handle, eliminating the need for long suction lines that can cause losses in efficiency.

- Space-Saving Design As submersible pumps are installed underwater, they free up valuable surface space, making them ideal for compact areas where traditional pumps may not fit.

- Reduced Noise Levels Operating underwater reduces noise pollution, making submersible slurry pumps a favorable option for environments where reducing sound is a priority.

- Minimal Maintenance With fewer mechanical parts exposed to air, submersible slurry pumps tend to require less maintenance, resulting in lower operational costs over time.

Insights into a Submersible Slurry Pump Factory

A standard submersible slurry pump factory is a hub of innovation and quality manufacturing. Such facilities typically utilize advanced technology and automated processes to ensure precision in the production of pumps.

Quality Control Factories maintain stringent quality control protocols, subjecting pumps to rigorous testing for durability, efficiency, and performance before they leave the production line.

Research and Development Continuous investment in research and development allows manufacturers to stay ahead of industry challenges, developing new models that address emerging needs in various sectors.

Sustainability Practices Many factories are now adopting sustainable practices, focusing on reducing carbon footprints and utilizing eco-friendly materials. This commitment not only benefits the environment but also enhances the brand reputation among increasingly environmentally-conscious consumers.

In conclusion, standard submersible slurry pump factories play an indispensable role in producing essential equipment that supports a wide array of industries. The advanced engineering behind these pumps ensures they remain integral components in managing challenging fluid applications effectively. As industries continue to evolve, the demand for reliable and efficient submersible slurry pumps will undoubtedly increase, prompting ongoing innovation in their design and manufacturing processes.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025