Dec . 09, 2024 17:53 Back to list

slurry pump components suppliers

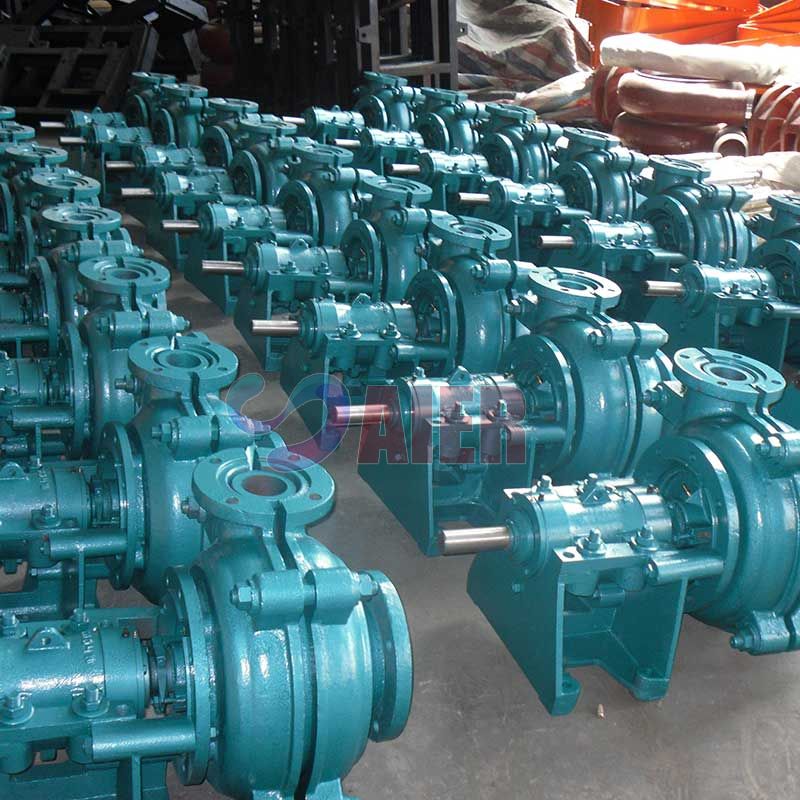

Understanding Slurry Pump Components and Choosing the Right Suppliers

Slurry pumps are vital equipment in various industries, especially in mining, construction, and wastewater management. These pumps are designed to handle slurries—thick mixtures of solids and liquids—that can be abrasive and corrosive. The efficiency and longevity of slurry pumps depend significantly on the quality of their components. Therefore, selecting the right suppliers for slurry pump components is crucial for maintaining operational efficiency and minimizing downtime.

Key Components of Slurry Pumps

1. Pump Housing The housing is the outer structure of the pump, designed to withstand high pressures and abrasive materials. Typically made from materials like cast iron or alloy, its integrity is essential for maintaining pump performance.

2. Impeller The impeller is the heart of the slurry pump, responsible for moving the slurry through the pump. Impellers are usually constructed from hard materials, often featuring a hard chrome or rubber lining to protect against wear and corrosion. The design of the impeller can significantly affect the pump’s efficiency and flow rate.

3. Suction and Discharge Strainers These components ensure that large solids do not enter the pump, which can lead to blockages or damage. Properly designed strainers can enhance the operational reliability of the pump.

4. Seals and Bearings High-quality seals are essential to prevent leakage of the slurry and to maintain pressure within the pump. Bearings must be durable enough to withstand the harsh operating conditions while maintaining the pump's alignment and minimizing friction.

5. Drive Mechanism The drive mechanism, which can be electric or hydraulic, is responsible for converting energy into mechanical motion to drive the impeller. Efficient and reliable drive mechanisms are crucial for overall pump performance.

Choosing the Right Suppliers

slurry pump components suppliers

Selecting the right supplier for slurry pump components is a critical decision that can impact the performance of your equipment

. Here are some factors to consider1. Quality Assurance Verify whether the supplier follows stringent quality control procedures. Look for certifications like ISO 9001 that indicate adherence to international quality standards. High-quality components will not only enhance pump performance but also extend its lifecycle.

2. Material Selection Ensure that the supplier uses materials suitable for the specific type of slurry being pumped. For example, corrosive slurries require special materials that resist wear and corrosion. Knowledge of material properties is crucial in choosing the right components.

3. Customization Every operation has unique needs based on the type of slurry, flow rates, and environmental conditions. A good supplier should offer customized solutions tailored to your specific requirements.

4. Technical Support After-sales service is important in maintaining pump efficiency. Suppliers offering robust technical support can help troubleshoot issues and provide maintenance guidance, which can save time and reduce costs in the long run.

5. Reputation and Experience Research the supplier’s reputation in the industry. Experienced suppliers with a track record of successful deliveries and satisfied customers are more likely to provide reliable components. Customer testimonials and case studies can provide insights into their performance.

6. Pricing and Delivery Competitive pricing is essential, but it should not compromise quality. Additionally, assess the supplier's delivery times. Timely delivery of components is critical to minimizing downtime in operations.

Conclusion

Investing in high-quality slurry pump components can significantly improve efficiency and durability. As industries evolve, the demand for reliable slurry pumps and their components will continue to grow. Selecting the right suppliers is a key factor that influences this reliability. By focusing on quality, material suitability, customization capabilities, and customer support, businesses can ensure optimal performance from their slurry pump systems. In a world where operational efficiency is paramount, making an informed choice about slurry pump components and their suppliers is a step toward sustained success.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025