Xan . 09, 2025 11:29 Back to list

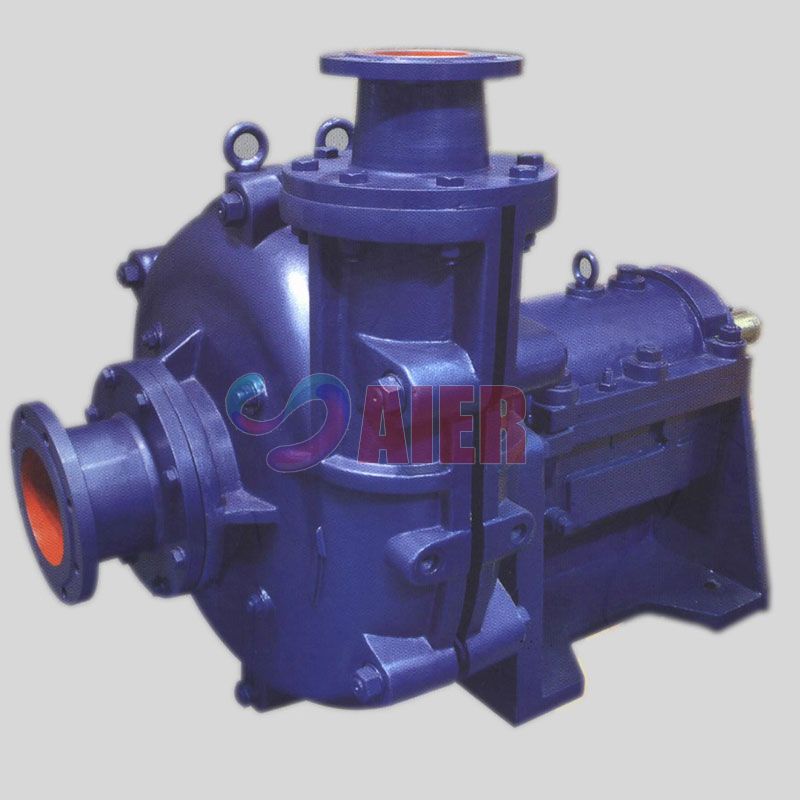

fgd pump

In the realm of industrial processes, the FGD pump, or Flue Gas Desulfurization pump, stands as an indispensable component, crucial for maintaining environmental compliance and operational efficiency. This specialized pump is designed to handle the demanding requirements of removing sulfur dioxide from exhaust flue gases in power plants and industrial facilities.

From an authoritative standpoint, leading industry standards such as those from the Hydraulic Institute and other international bodies provide comprehensive guidelines for the design, selection, and maintenance of FGD pumps. Adhering to these standards ensures compliance with environmental regulations, bolsters operational efficiency, and enhances safety—a trifecta of benefits that solidify the pump's cornerstone role in industrial applications. Trustworthiness in FGD pump technology lies in the empirical data and field-proven performance metrics that manufacturers provide. Facilities looking to implement or upgrade their FGD systems can draw on case studies and user testimonials that highlight the long-term reliability and cost-effectiveness of specific pump models. Collaborating directly with manufacturers for tailored solutions can guarantee that the pump systems installed are optimized for the unique demands of each plant. In conclusion, the FGD pump is far more than a functional necessity—it is integral to sustainable industrial practices. Robust design, expert-backed selection, and adherence to authoritative standards collectively fortify the pump's role in flue gas desulfurization. Facility managers and engineers can ensure maximum efficiency and environmental compliance by leveraging this breadth of knowledge and expertise, underscoring the pump's pivotal contribution to modern industry.

From an authoritative standpoint, leading industry standards such as those from the Hydraulic Institute and other international bodies provide comprehensive guidelines for the design, selection, and maintenance of FGD pumps. Adhering to these standards ensures compliance with environmental regulations, bolsters operational efficiency, and enhances safety—a trifecta of benefits that solidify the pump's cornerstone role in industrial applications. Trustworthiness in FGD pump technology lies in the empirical data and field-proven performance metrics that manufacturers provide. Facilities looking to implement or upgrade their FGD systems can draw on case studies and user testimonials that highlight the long-term reliability and cost-effectiveness of specific pump models. Collaborating directly with manufacturers for tailored solutions can guarantee that the pump systems installed are optimized for the unique demands of each plant. In conclusion, the FGD pump is far more than a functional necessity—it is integral to sustainable industrial practices. Robust design, expert-backed selection, and adherence to authoritative standards collectively fortify the pump's role in flue gas desulfurization. Facility managers and engineers can ensure maximum efficiency and environmental compliance by leveraging this breadth of knowledge and expertise, underscoring the pump's pivotal contribution to modern industry.

Next:

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025