Nov . 12, 2024 19:50 Back to list

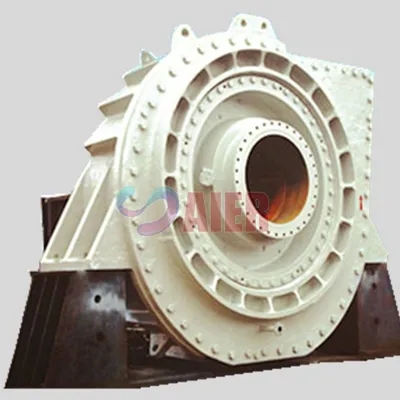

china sand slurry pump rubber liner

The Significance of Rubber Liners in China’s Sand Slurry Pumps

In the realm of industrial applications, particularly in the mining, dredging, and construction sectors, the efficient transportation of sand and slurry is crucial. Among the various equipment designed for these purposes, sand slurry pumps play a pivotal role. A critical component of these pumps is the rubber liner, which enhances their performance and durability. This article explores the significance of rubber liners in China’s sand slurry pumps, focusing on their benefits, manufacturing processes, and sustainability.

Understanding Sand Slurry Pumps

Sand slurry pumps are specialized pumps designed to transport mixtures of water, sand, and other solid materials. They are essential in various applications, including mineral processing, wastewater treatment, and dredging. The ability to handle abrasive and corrosive materials makes these pumps indispensable. However, the harsh operational environment often leads to rapid wear and tear of the pump components, necessitating the use of protective materials like rubber liners.

Advantages of Rubber Liners

One of the primary advantages of rubber liners is their excellent abrasion resistance. Sand and other solid particles can cause significant wear on pump components made of metal. Rubber, being a softer material, can absorb impact without suffering from substantial erosion. This property extends the lifespan of the pump and reduces maintenance costs over time.

Furthermore, rubber liners are inherently resistant to corrosion and chemical degradation. This characteristic is particularly important in applications where pumps come into contact with potentially corrosive materials. By using rubber liners, operators can enhance the overall durability of the pump, ensuring consistent performance even in challenging conditions.

Another significant benefit of rubber liners is their ability to reduce operational noise. Traditional metal liners can amplify noise levels during operation, which can be a concern in urban and environmentally sensitive areas. Rubber liners help dampen these sounds, contributing to a quieter working environment.

Manufacturing Processes

china sand slurry pump rubber liner

China has established itself as a leading manufacturer of sand slurry pumps and their components, including rubber liners. The production of rubber liners involves several sophisticated processes, beginning with the selection of high-quality rubber compounds designed for resistance to abrasives and chemicals.

The manufacturing process typically includes mixing raw materials, molding the rubber into the desired shape, and curing it to achieve optimal strength and durability. Advanced techniques, such as adding reinforcing agents and utilizing specific molding technologies, enhance the performance characteristics of the liners.

In addition, the production facilities in China are often equipped with modern technologies, ensuring high precision and consistency in the manufacturing process. Quality control is a critical aspect, with multiple tests conducted to ensure that the liners meet international standards for performance and durability.

Sustainability Considerations

As environmental concerns grow, the sustainability of industrial practices has become increasingly important. The rubber used in liners can be derived from both natural and synthetic sources. Natural rubber, in particular, is renewable and biodegradable, making it an eco-friendly choice for manufacturers and consumers alike.

Moreover, advancements in recycling technologies are allowing for the more effective reuse of worn-out rubber liners, further reducing waste. Companies in China are beginning to adopt more sustainable practices, incorporating recycled materials into new products and emphasizing the importance of end-of-life product management.

Conclusion

The role of rubber liners in China’s sand slurry pumps cannot be overstated. Their ability to extend pump life, minimize maintenance costs, and mitigate noise makes them an essential component in the effective operation of these machines. With robust manufacturing processes and a growing focus on sustainability, the future of rubber liners in the mining and construction industries looks promising. As technology advances and more environmentally friendly practices are adopted, the impact of these liners will only continue to enhance the efficiency and effectiveness of sand slurry pumps globally.

-

Heavy Duty Slurry Pump Manufacturers OEM & High-Quality Solutions

NewsMay.18,2025

-

Top China Submersible Slurry Pump Supplier Durable & Efficient Solutions

NewsMay.17,2025

-

Submersible Pump Spares Manufacturer High-Quality & Durable Components

NewsMay.17,2025

-

Vertical Centrifugal Sump Pump Supplier China Factory Solutions

NewsMay.16,2025

-

Vertical Spindle Slurry Pump Suppliers High-Quality China Manufacturers

NewsMay.16,2025

-

High-Quality Casting Submersible Pump Parts Manufacturer Durable Solutions

NewsMay.16,2025