Dùbh . 07, 2024 11:55 Back to list

slurry pump casing manufacturer

Understanding the Importance of Slurry Pump Casing Manufacturers

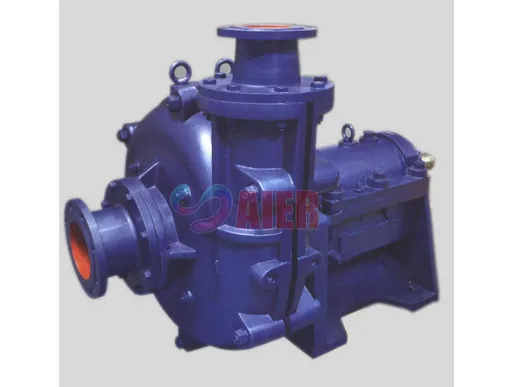

In the world of industrial pumps, slurry pumps play a crucial role in transporting abrasive and viscous fluids that contain solid particles. The effectiveness and efficiency of these pumps largely depend on their design and construction, particularly the casing. This article delves into the significance of slurry pump casing manufacturers, their role in the industry, and the factors to consider when selecting a manufacturer for your needs.

The Role of Slurry Pump Casings

The casing of a slurry pump serves as the protective outer shell of the pump, safeguarding its internal components from wear and tear caused by abrasive materials. It also plays a critical role in determining the pump's performance characteristics, such as flow rate and pressure. A robust and well-designed casing can extend the life of the pump, enhance efficiency, and reduce operational costs.

Given the challenging nature of the materials being pumped, casings must be constructed from durable materials that can withstand high wear rates and corrosion. Manufacturers typically use high-chrome cast iron or other advanced materials designed to handle the harsh environments commonly encountered in mining, construction, and wastewater treatment applications.

Choosing the Right Manufacturer

When selecting a slurry pump casing manufacturer, there are several key factors to consider

1. Experience and Reputation A manufacturer with a long-standing presence in the industry is likely to have extensive knowledge and expertise in producing high-quality pump casings. Researching customer reviews and industry ratings can provide insights into their reputation.

slurry pump casing manufacturer

2. Material Quality The quality of materials used in manufacturing pump casings is paramount. Look for manufacturers who source high-grade materials to ensure durability and reliability. A good manufacturer will be transparent about their material selection process.

3. Customization Options Each application may have unique requirements, so it's beneficial to partner with a manufacturer that offers customization options. They should be able to tailor the design and specifications of the casing to meet your specific needs, enhancing performance and longevity.

4. Manufacturing Technology Advanced manufacturing processes and technologies can significantly impact the quality and precision of the final product. Manufacturers who invest in modern equipment and techniques often produce better and more reliable casings.

5. Support and Service Post-purchase support and service are essential aspects of a manufacturer’s offering. A reliable manufacturer should provide assistance with installation, maintenance, and repairs to ensure optimal performance throughout the pump's lifecycle.

6. Certifications and Standards Compliance Ensure the manufacturer adheres to industry standards and possesses the necessary certifications. Compliance with quality management systems such as ISO 9001 can be an indicator of a commitment to quality.

Conclusion

The selection of a slurry pump casing manufacturer can significantly affect the operational efficiency and lifespan of your pumping systems. Understanding the roles and responsibilities of these manufacturers, along with the critical factors in choosing the right one, can lead to better decision-making and investment. By prioritizing quality, customization, and support, industries can ensure that they are equipped with the best possible casings to handle the demanding challenges presented by slurry transport. Whether in mining, construction, or wastewater management, the right slurry pump casing can make all the difference in achieving operational excellence.

-

China Portable Slurry Pump Manufacturer - Durable & Efficient Submersible Design

NewsMay.29,2025

-

High-Quality Submersible Slurry Pumps Reliable Manufacturer & Supplier

NewsMay.29,2025

-

High-Quality Sand Dredge Pump 8 Durable Manufacturer & Supplier

NewsMay.29,2025

-

Electric Submersible Slurry Pump - Durable & Efficient China Suppliers

NewsMay.29,2025

-

Submersible Slurry Pump with Agitator Durable China Suppliers & Manufacturers

NewsMay.29,2025

-

Vertical Sump Pump Rubber Lined - Durable Corrosion-Resistant Design China Manufacturers

NewsMay.29,2025