Sult . 24, 2024 19:44 Back to list

centrifugal slurry pump liner suppliers

Understanding the Importance of Centrifugal Slurry Pump Liners and Their Suppliers

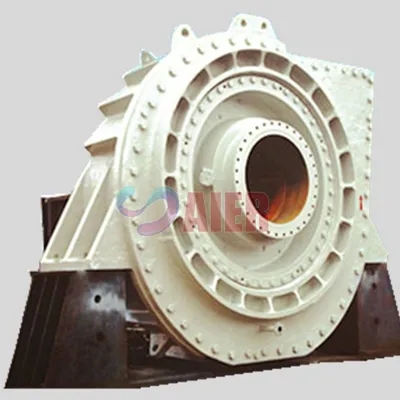

Centrifugal slurry pumps are critical components in various industrial applications, particularly in mining, wastewater treatment, and dredging. These pumps are designed to handle abrasive and viscous slurries, which often contain solid particles. One of the essential elements in maintaining the efficiency and longevity of these pumps is the liner, which protects the pump from wear and tear caused by the aggressive nature of the materials being transported. Consequently, identifying reliable centrifugal slurry pump liner suppliers is crucial for businesses aiming to ensure optimal pump performance and minimize downtime.

The Role of Slurry Pump Liners

Slurry pump liners serve as a protective barrier within the pump casing, shielding it from the abrasive effects of the slurry. The liners are subjected to harsh operating conditions, including high pressure, variable flow rates, and the aggressive characteristics of the materials being pumped. Over time, liners can wear down, leading to reduced efficiency, increased energy consumption, and potential pump failure. This is why selecting high-quality liners from reputable suppliers is vital.

There are typically two types of liners used in centrifugal slurry pumps rubber liners and metal liners. Rubber liners are known for their exceptional resistance to abrasion and corrosion, making them suitable for handling fine particles and less aggressive slurries. On the other hand, metal liners, often made from hard alloys, are preferred for their durability in high-impact applications with coarse solids. Understanding the specific requirements of your slurry application will guide the selection of the appropriate liner material.

Choosing the Right Supplier

When searching for centrifugal slurry pump liner suppliers, several factors must be considered to ensure that you are partnering with a reputable provider

1. Quality Assurance The first consideration should be the supplier's commitment to quality. Reliable suppliers often adhere to international quality standards and have certifications to back their claims. It is beneficial to look for suppliers who conduct rigorous testing of their products.

centrifugal slurry pump liner suppliers

2. Material Expertise Different applications require different materials. A supplier that offers a variety of liner materials—such as natural rubber, polyurethane, and various metal alloys—can better meet your specific needs. Additionally, suppliers should be knowledgeable about the properties and performance of these materials in various slurry conditions.

3. Customization Options Every industry has unique requirements. A good supplier should provide customization options to match the specific dimensions and specifications of your slurry pump. This may include tailored designs that enhance performance and extend the life of the pump.

4. Technical Support Suppliers should offer technical support and guidance in selecting the right liner for your application. This could involve assistance in analyzing slurry characteristics and recommending the best materials and liners accordingly.

5. Reputation and Experience A supplier with a long-standing reputation in the industry is often more reliable. Check for customer reviews, testimonials, and case studies that showcase their performance and customer service.

6. Delivery and Logistics Timely delivery of liners is crucial for minimizing downtime in operations. Suppliers should have efficient logistics in place to ensure that products are delivered on schedule.

Conclusion

Centrifugal slurry pump liners are vital components that significantly impact the efficiency and longevity of pump operations. Choosing the right liner and supplier can enhance the performance of your slurry systems and reduce maintenance costs. By focusing on quality, material expertise, customization capabilities, technical support, reputation, and logistics, businesses can find reputable suppliers that meet their specific needs.

In an industry where downtime can have serious financial implications, investing time and resources in selecting the right centrifugal slurry pump liner suppliers pays off. By ensuring that pump systems are fitted with durable and reliable liners, companies can maintain operational efficiency and ultimately drive growth and productivity. In conclusion, a strategic partnership with the right supplier can lead to long-term benefits, ultimately ensuring that your processes run smoothly and effectively.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025