Dec . 03, 2024 13:32 Back to list

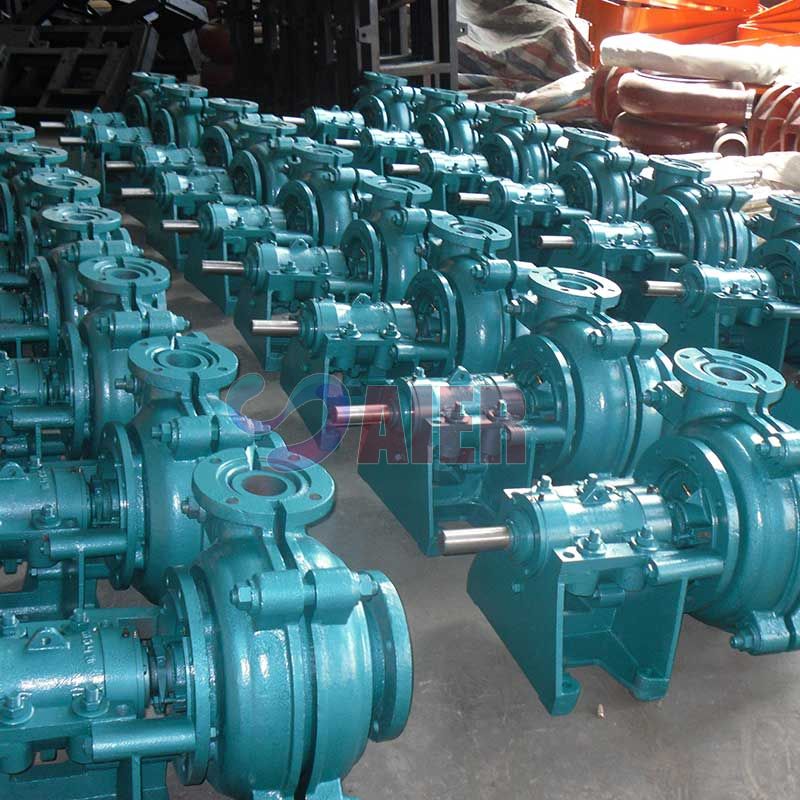

sewage pump manufacturers

The Role of Sewage Pump Manufacturers in Modern Infrastructure

Sewage pump manufacturers play a crucial role in the functionality of modern infrastructure. As cities expand and populations grow, the need for effective wastewater management systems becomes increasingly paramount. Sewage pumps are integral components of these systems, designed to transport sewage and wastewater from residential, commercial, and industrial sectors to treatment facilities. In this article, we will explore the significance of sewage pump manufacturers, the types of sewage pumps available, and the innovations shaping the industry.

Importance of Sewage Pump Manufacturers

Sewage pump manufacturers are responsible for creating reliable pumps that ensure the safe and efficient transport of wastewater. These manufacturers balance engineering excellence with regulatory compliance to create products that meet stringent industry standards. A well-functioning sewage pump system mitigates environmental hazards, prevents contamination of water supplies, and promotes public health. These manufacturers must not only focus on the performance of their pumps but also on their durability and maintenance to cater to the demanding conditions in which they operate.

Types of Sewage Pumps

There are various types of sewage pumps, each designed for specific applications

. The most common types include1. Submersible Sewage Pumps These pumps are designed to operate underwater, often used in residential and commercial applications for pumping sewage from basements or below-grade areas. Their design allows for efficient operation, minimizing the risk of clogging.

2. Effluent Pumps Designed primarily for moving liquid waste, effluent pumps are typically used for greywater applications. They have smaller solids-handling capabilities compared to sewage pumps and are ideal for draining water from septic tanks or washing machine discharge.

3. Centrifugal Sewage Pumps These pumps utilize a rotating impeller to move wastewater. They are widely used in industrial settings and municipal wastewater treatment facilities due to their efficiency in handling large volumes of fluid.

4. Grinder Pumps Equipped with a powerful grinding mechanism, these pumps break down solids into smaller particles, allowing for the easy transport of thick sewage. Grinder pumps are often used in low-lying areas where traditional sewage systems cannot reach.

sewage pump manufacturers

5. Sewage Ejector Pumps These pumps are designed to lift sewage from basements or low-level drains to the main sewage line. They efficiently eject waste materials through a discharge pipe, typically positioned at a higher elevation.

Innovations in Sewage Pump Manufacturing

The sewage pump manufacturing industry is continuously evolving, driven by technological advancements and environmental considerations. Innovations include

1. Smart Pump Technology Incorporating IoT technology, smart pumps can monitor performance metrics, send alerts for maintenance needs, and optimize energy consumption. This not only enhances operational efficiency but also extends the lifespan of the equipment.

2. Energy Efficiency With increasingly stringent energy regulations, manufacturers are focusing on creating pumps that consume less energy while maintaining performance. This is critical for reducing operational costs and environmental impact.

3. Advanced Materials The use of corrosion-resistant materials and coatings in the manufacture of sewage pumps extends their durability. Innovations such as thermoplastic and stainless steel components help ensure the pumps can withstand harsh conditions.

4. Eco-friendly Solutions With a growing emphasis on environmentally sustainable practices, manufacturers are designing pumps that minimize noise pollution and reduce emissions. These innovations are essential for protecting ecosystems and promoting the health of local communities.

5. Enhanced Safety Features To address potential hazards associated with sewage pumping, manufacturers are incorporating advanced safety mechanisms, such as overload protection and automatic shut-off features, to render their products safer for both operators and the environment.

Conclusion

Sewage pump manufacturers are pivotal to the infrastructure that supports urban living. By providing essential solutions for wastewater management, these manufacturers contribute significantly to public health and environmental preservation. As technology progresses, we can anticipate further innovations in the field, leading to more efficient, durable, and environmentally-friendly sewage pump systems. Investing in high-quality sewage pumps is not only a matter of compliance but also a proactive step towards sustaining our infrastructure and the environment for future generations.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025