Oct . 30, 2024 22:43 Back to list

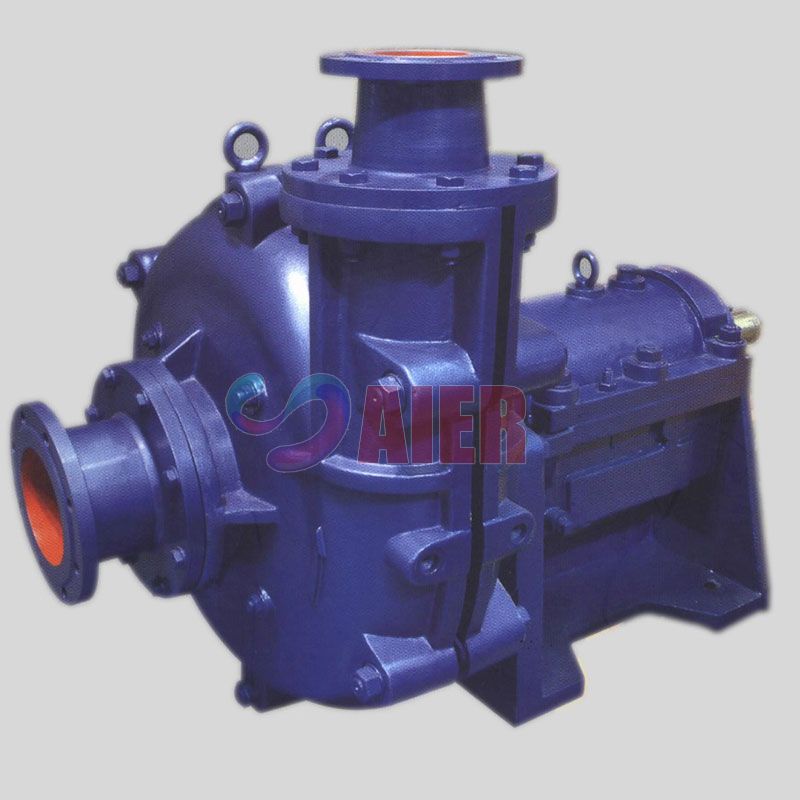

wholesale centrifugal slurry pump

Understanding Wholesale Centrifugal Slurry Pumps

Centrifugal slurry pumps are essential machines in various industries where the transport of abrasive and viscous materials is required. These pumps are designed to handle slurries, which are mixtures of solid particles and liquids, making them vital in sectors such as mining, mineral processing, construction, and wastewater treatment. When exploring the wholesale market for centrifugal slurry pumps, it is crucial to understand their functionality, advantages, applications, and the factors to consider when purchasing.

Functionality of Centrifugal Slurry Pumps

Centrifugal slurry pumps operate using a rotating impeller to impart kinetic energy to the slurry, converting it into hydraulic energy. When the impeller spins, it creates a centrifugal force that pushes the slurry through the pump. As the flow accelerates through the impeller and into the pump volute, the pressure increases, allowing the slurry to be discharged at a higher elevation or distance. This mechanism makes centrifugal slurry pumps particularly efficient for transporting heavy and concentrated slurries over long distances.

Advantages of Centrifugal Slurry Pumps

One of the key advantages of centrifugal slurry pumps is their ability to handle high-solid content mixtures without clogging. Designed with durable materials, these pumps can resist wear and tear from abrasive particles in the slurry, ensuring longevity and reliability. Furthermore, centrifugal pumps are generally easier to maintain compared to positive displacement pumps, as they have fewer moving parts and less complex mechanisms. This ease of maintenance, coupled with their high efficiency, makes them a preferred choice in wholesale markets.

wholesale centrifugal slurry pump

Applications in Various Industries

Centrifugal slurry pumps find applications across a myriad of industries. In the mining sector, they are utilized to transport mineral slurries from mining sites to processing plants. In construction, these pumps move concrete slurries and other materials during structural development. Moreover, in wastewater treatment facilities, they are essential for moving sludge and other waste materials. The versatility of centrifugal slurry pumps makes them invaluable in any process that involves the handling of thick fluids.

Factors to Consider When Purchasing

When considering the wholesale purchase of centrifugal slurry pumps, several factors should be examined. Firstly, assess the specifications of the pump, including flow rate, head height, and the type of slurry being handled. It's essential to select a pump that meets the specific requirements of your application. Secondly, evaluate the materials used in the pump's construction. Pumps made from high-chrome alloys or rubber-lined options tend to offer better resistance against abrasion and corrosion. Lastly, consider the reputation and support services of the supplier or manufacturer. A well-established supplier providing technical support and after-sales service can significantly enhance the operational efficiency of your pumping system.

In conclusion, wholesale centrifugal slurry pumps play a critical role in various industries by effectively managing the transport of abrasive slurries. Understanding their functionality, advantages, applications, and key purchasing factors can help businesses make informed decisions and optimize their operations. Investing in high-quality slurry pumps will not only enhance efficiency but also mitigate maintenance costs, ensuring a smoother workflow in demanding environments.

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025