Déc . 19, 2024 05:11 Back to list

Exploring the Benefits and Applications of Submersible Pumps in Various Industries

Understanding Submersible Pumps An Essential Component in Fluid Management

Submersible pumps are innovative devices that play a crucial role in various industries by effectively managing the movement of fluids. Whether it’s for agricultural irrigation, groundwater extraction, sewage treatment, or industrial applications, submersible pumps offer efficiency and reliability. In this article, we will delve into the workings of submersible pumps, their applications, advantages, and maintenance considerations.

What is a Submersible Pump?

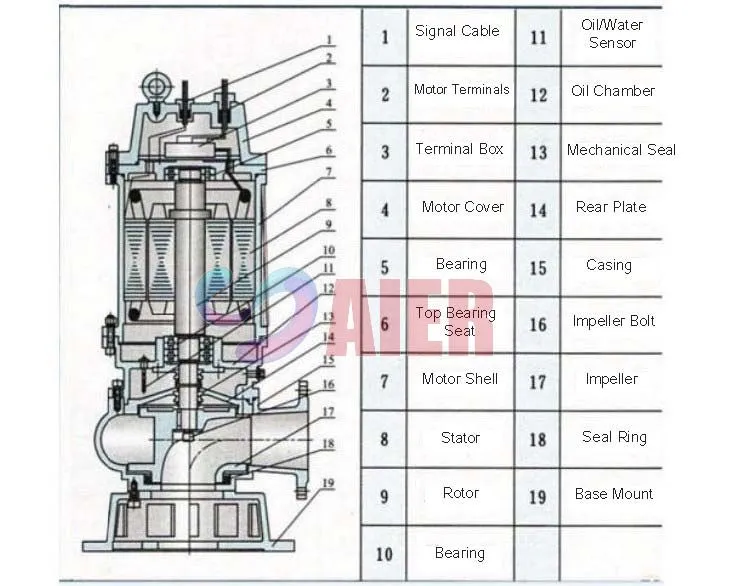

A submersible pump is a type of water pump that is designed to be submerged in the liquid it is pumping. Unlike conventional pumps that operate above the water surface, submersible pumps consist of a sealed motor that allows them to operate underwater. This design typically includes an electrical motor, a pump body, an impeller, and discharge piping. These pumps can effectively transport water or other fluids from one location to another while mitigating the risk of vapor locking, which can occur in surface pumps due to air pressure differences.

How Submersible Pumps Work

When a submersible pump is submerged in water, the electric motor runs continuously, driving the impeller inside the pump. As the impeller spins, it creates a low-pressure area at the center of the pump, which draws water in through the pump inlet. The rotational motion of the impeller pushes the water upward through the discharge pipe, allowing it to be moved to the surface or redirected to a specific location.

The typical construction of a submersible pump includes durable materials, such as stainless steel, to withstand harsh environments and prevent corrosion. Most submersible pumps are designed for depths ranging from a few meters to hundreds of meters, depending on their specific applications. This versatility makes them suitable for various settings, from residential areas to large industrial sites.

Applications of Submersible Pumps

Submersible pumps are utilized in an array of applications

1. Agricultural Use In agriculture, these pumps are essential for irrigation systems. They enable farmers to extract groundwater from wells and transport it to fields, ensuring crops receive adequate hydration.

2. Sewage and Wastewater Management Submersible pumps are commonly deployed in wastewater treatment plants and sewage systems. They handle the transportation of sewage and stormwater, ensuring proper drainage and treatment.

submersible pump

3. Industrial Applications Factories and industrial sites use submersible pumps for various processes, including the removal of unwanted water from construction sites or the transfer of liquids in manufacturing.

4. Residential Use Homeowners use submersible pumps for domestic applications, such as draining basements, emptying swimming pools, or maintaining water levels in ponds and fountains.

Advantages of Submersible Pumps

Submersible pumps offer several benefits that distinguish them from traditional pumping methods

- Efficiency Submersible pumps are generally more energy-efficient than surface pumps. The design allows them to push water to the surface rather than pull it, reducing energy consumption.

- Reduced Noise As submersible pumps are located underwater, they operate quietly, making them ideal for residential areas where noise pollution needs to be minimized.

- Space-Saving Design These pumps have a compact design, making them suitable for sites with limited space.

- Versatile Applications Their wide range of applications makes them adaptable to various industrial, agricultural, and residential settings.

Maintenance Considerations

Despite their advantages, submersible pumps require proper maintenance to ensure long-lasting performance. Regular inspections should be conducted to check for signs of wear, corrosion, or malfunction. It's essential to clean the pump regularly to prevent debris accumulation that could impede performance. Additionally, users should monitor the electrical components to ensure they are functioning correctly and without leaks.

In conclusion, submersible pumps are vital tools in fluid management, contributing to efficiency across numerous sectors. Their unique design, applications, and advantages make them invaluable for irrigation, sewage management, industrial processes, and more. Understanding their operation and maintenance ensures optimal performance and longevity, reinforcing their role as essential components in modern fluid handling systems. As technology advances, we can expect to see innovations in submersible pump design that will further enhance their effectiveness and applications.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025