Fév . 17, 2025 20:03 Back to list

high quality chemical centrifugal slurry pump

Choosing the right centrifugal sewage pump is crucial for ensuring high efficiency in wastewater management. These pumps are essential in industries and municipal applications to transport sewage, slurry, and other waste materials. To achieve optimal results, one must consider key factors that enhance performance, durability, and operational efficiency.

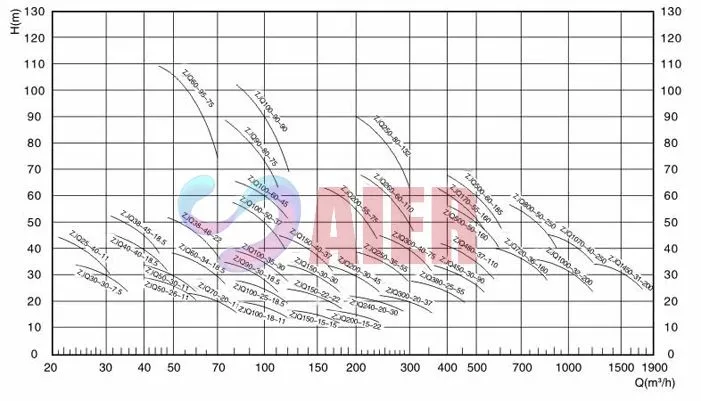

Trustworthiness is also reflected in user testimonials and case studies highlighting real-world applications of high-quality centrifugal sewage pumps. Testimonials from peers in similar industries provide insights into the reliability and performance of these pumps under various conditions. Furthermore, detailed case studies showcasing how specific models have successfully operated in challenging environments emphasize their capability and the tangible benefits experienced by end-users, such as reduced energy consumption and maintenance costs. An exemplary centrifugal sewage pump should also adhere to eco-friendly standards. The environmental impact of pumping systems is increasingly important in today's market. Modern pumps that are engineered to use energy more efficiently not only lower operational costs but also contribute to sustainability goals. Prioritizing energy-efficient models with a lower carbon footprint aligns businesses with global environmental initiatives and portrays them as responsible corporate citizens. When evaluating different models, it is essential to consult comprehensive technical data sheets and performance curves. These documents offer invaluable information, enabling an informed decision based on the technical nuances of pressure, flow rates, and overall system compatibility. Technical support from the manufacturer is equally important for seamless integration and maintenance. In conclusion, choosing a high-quality centrifugal sewage pump involves a thorough consideration of experience, expertise, authoritativeness, and trustworthiness. Prioritizing these factors ensures reliable performance, cost savings, and compliance with environmental standards. By investing in a reputable pump now, industries and municipalities can secure long-term benefits and contribute to a cleaner, more sustainable future.

Trustworthiness is also reflected in user testimonials and case studies highlighting real-world applications of high-quality centrifugal sewage pumps. Testimonials from peers in similar industries provide insights into the reliability and performance of these pumps under various conditions. Furthermore, detailed case studies showcasing how specific models have successfully operated in challenging environments emphasize their capability and the tangible benefits experienced by end-users, such as reduced energy consumption and maintenance costs. An exemplary centrifugal sewage pump should also adhere to eco-friendly standards. The environmental impact of pumping systems is increasingly important in today's market. Modern pumps that are engineered to use energy more efficiently not only lower operational costs but also contribute to sustainability goals. Prioritizing energy-efficient models with a lower carbon footprint aligns businesses with global environmental initiatives and portrays them as responsible corporate citizens. When evaluating different models, it is essential to consult comprehensive technical data sheets and performance curves. These documents offer invaluable information, enabling an informed decision based on the technical nuances of pressure, flow rates, and overall system compatibility. Technical support from the manufacturer is equally important for seamless integration and maintenance. In conclusion, choosing a high-quality centrifugal sewage pump involves a thorough consideration of experience, expertise, authoritativeness, and trustworthiness. Prioritizing these factors ensures reliable performance, cost savings, and compliance with environmental standards. By investing in a reputable pump now, industries and municipalities can secure long-term benefits and contribute to a cleaner, more sustainable future.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025