دسامبر . 18, 2024 13:54 Back to list

Premium Warman Centrifugal Slurry Pump Manufacturer for High-Performance Applications

High-Quality Warman Centrifugal Slurry Pump Factory

In the world of industrial pumping solutions, the demand for reliable and high-performance equipment has never been higher. Among various types of pumps, centrifugal slurry pumps, particularly those based on the renowned Warman design, stand out for their durability, efficiency, and ability to handle abrasive materials. This article will delve into the critical aspects of a high-quality Warman centrifugal slurry pump factory, highlighting its manufacturing process, quality control measures, and the benefits of utilizing such pumps in various applications.

Manufacturing Process

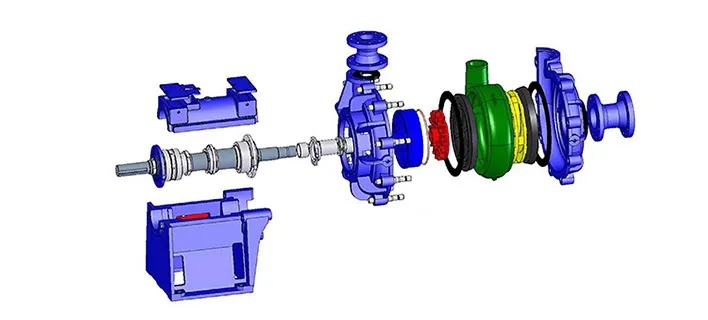

A high-quality Warman centrifugal slurry pump factory incorporates advanced manufacturing techniques and state-of-the-art technology to produce pumps that meet stringent industry standards. The manufacturing process typically begins with the selection of robust materials, such as high-chrome alloys, which are essential for the construction of the pump casing, impeller, and other critical components. These materials are chosen specifically for their resistance to wear and corrosive properties, ensuring longevity and reliability even in the most challenging environments.

Once the materials are procured, the factory employs precision machining to manufacture pump parts with tight tolerances. CNC (Computer Numerical Control) machines play a pivotal role in this process, allowing for consistent accuracy and high production rates. After machining, components undergo rigorous surface treatment processes to enhance their durability, such as hardening or coating, which further improves their resistance to abrasion and chemical erosion.

Quality Control Measures

Quality control is paramount in a high-quality Warman centrifugal slurry pump factory. Each stage of the manufacturing process is closely monitored and evaluated to ensure that the final product meets or exceeds industry standards. Rigorous testing procedures are integral to this process, which include hydraulic testing, performance testing, and endurance testing.

Hydraulic testing involves checking the pump's capacity to handle various flow rates and pressures, ensuring it performs optimally under real-world conditions. Performance testing assesses the efficiency of the pump, verifying that it meets the expected specifications. Additionally, endurance testing subjects the pump to prolonged operational conditions to identify potential failure points and mitigate them before the pumps are delivered to customers.

high quality warman centrifugal slurry pump factory

Further quality assurance measures include inspections of raw materials and components, as well as the implementation of standardized procedures that align with international certifications such as ISO 9001. These practices not only ensure the reliability of the pumps but also build trust with customers who depend on them for their operations.

Benefits of Warman Centrifugal Slurry Pumps

Utilizing high-quality Warman centrifugal slurry pumps offers numerous advantages across various sectors, including mining, mineral processing, and civil engineering. These pumps are designed to handle highly abrasive and corrosive materials with ease, making them ideal for transporting slurry mixtures that consist of solids and liquids.

One of the key benefits is their high efficiency and reliability, which translates into reduced operational costs. Because these pumps are designed for continuous operation, they minimize downtime due to maintenance and repairs, thus enhancing productivity. Additionally, their modular design allows for easy replacement of worn parts, further prolonging service life and reducing overall maintenance costs.

Moreover, Warman slurry pumps are renowned for their versatility. They can be configured to handle a wide range of applications and materials, from thick slurries in mining operations to fine and corrosive fluids in chemical processes.

Conclusion

In conclusion, a high-quality Warman centrifugal slurry pump factory embodies a commitment to excellence in manufacturing and quality assurance. With advanced production techniques, rigorous testing, and a focus on reliability, these factories provide pumps that meet the demanding needs of various industries. Investing in high-quality slurry pumps ensures operational efficiency, reduced downtime, and enhanced durability, making them an indispensable asset in today’s industrial landscape.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025