دسامبر . 10, 2024 13:46 Back to list

china sump pump check valve vertical or horizontal factories

Understanding Sump Pump Check Valves Vertical vs. Horizontal Factories in China

Sump pumps are crucial devices in many industries, acting as the first line of defense against flooding and water accumulation. One of the key components of a sump pump system is the check valve, which ensures that water flows in the correct direction while preventing backflow. When considering the manufacturing of sump pump check valves, particularly in China, one of the dilemmas faced by engineers and decision-makers is whether to opt for vertical or horizontal designs. This article explores the characteristics, advantages, and potential applications of both types of check valves in sump pump systems.

The Role of Check Valves in Sump Pumps

Check valves are designed to control the flow of water in sump pump systems. They open to allow water to flow out of the sump pit when the pump is operating and close when the pump stops, thus preventing backflow. This is especially important in preventing water from re-entering the sump pit, which can lead to inefficient pump operation and potential system failures.

Vertical Check Valves Design and Application

Vertical check valves are characterized by their upright installation. They are often preferred in applications where space is limited or where gravity will assist in their operation. The vertical orientation allows for better drainage of fluids, as there is less chance for sediment to accumulate in the valve body.

Advantages of Vertical Check Valves

1. Space Efficiency Vertical check valves occupy less horizontal space, making them ideal for installations where space is at a premium. 2. Reduced Sediment Accumulation The vertical design minimizes the risk of sediment and debris gathering inside the valve, which can impair its function over time.

3. Minimized Flow Resistance Vertical check valves generally have lower flow resistance compared to their horizontal counterparts, allowing for more efficient water movement.

Applications Vertical check valves are often used in compact sump pump systems, basement drainage solutions, and in scenarios where vertical pumping is essential, such as in high-rise buildings or areas with significant elevation changes

.Horizontal Check Valves Design and Benefits

Horizontal check valves, on the other hand, are mounted parallel to the ground. This design is frequently used when a straightforward installation is needed, and it allows for easier maintenance and inspection.

china sump pump check valve vertical or horizontal factories

Advantages of Horizontal Check Valves

1. Ease of Maintenance Horizontal check valves are generally easier to access and maintain, as they can be located at convenient heights and positions.

2. Versatile Installation These valves can be installed in various orientations, providing greater flexibility in industrial and residential settings.

3. Robust Design Horizontal models tend to handle larger flow rates and can be designed to withstand significant pressure fluctuations, making them suitable for high-capacity applications.

Applications Horizontal check valves are commonly found in industrial sump pump systems, commercial buildings, and municipal water systems, where space is less of a concern, and higher flow rates are required.

Manufacturing Considerations in China

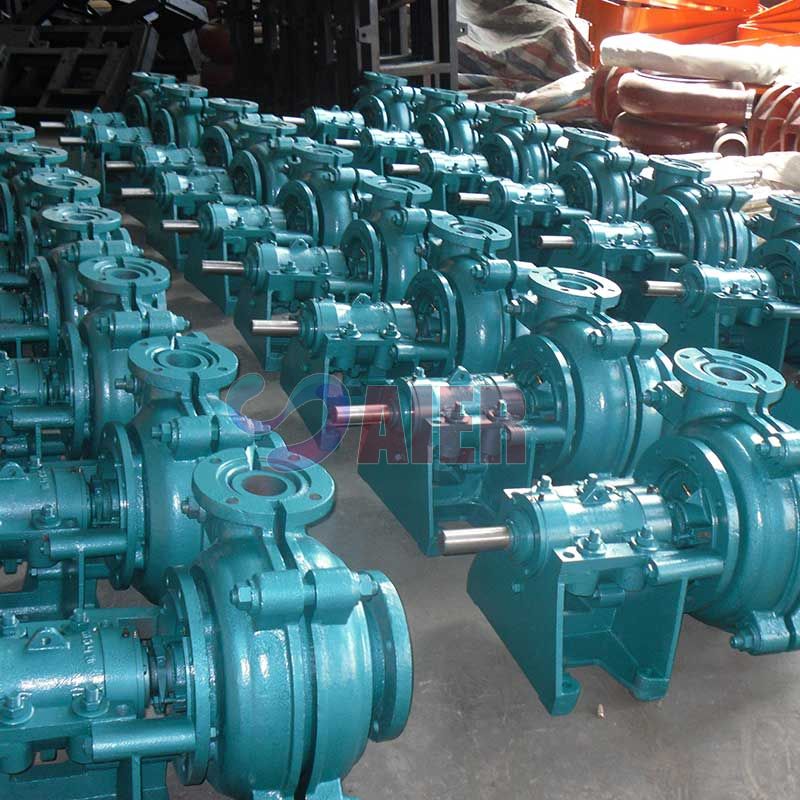

China is home to a multitude of factories specializing in the production of sump pump check valves. When choosing a manufacturing partner, it’s essential to consider several factors, including the factory's design capabilities, quality control measures, and experience in producing both vertical and horizontal check valves.

Quality Assurance Ensuring that the manufacturer adheres to international quality standards is crucial for the longevity and reliability of the check valves. Certifications such as ISO 9001 can indicate a commitment to quality management.

Material Selection The longevity of a check valve is often determined by the materials used in its construction. Factories that offer a variety of materials, including corrosion-resistant options, can provide products better suited for specific applications, whether in residential or industrial settings.

Conclusion

In conclusion, the choice between vertical and horizontal sump pump check valves hinges on the specific requirements of the application, available space, and maintenance considerations. Understanding the advantages of each type of valve can help stakeholders make informed decisions when partnering with manufacturers in China. As the demand for reliable water management systems continues to grow, the importance of selecting the right components cannot be overemphasized. By leveraging the capabilities of Chinese factories, companies can ensure effective water handling solutions that meet their operational needs.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025