Aza . 26, 2024 12:46 Back to list

Interchangeable Spare Parts for Slurry Pumps from Leading Factory Solutions

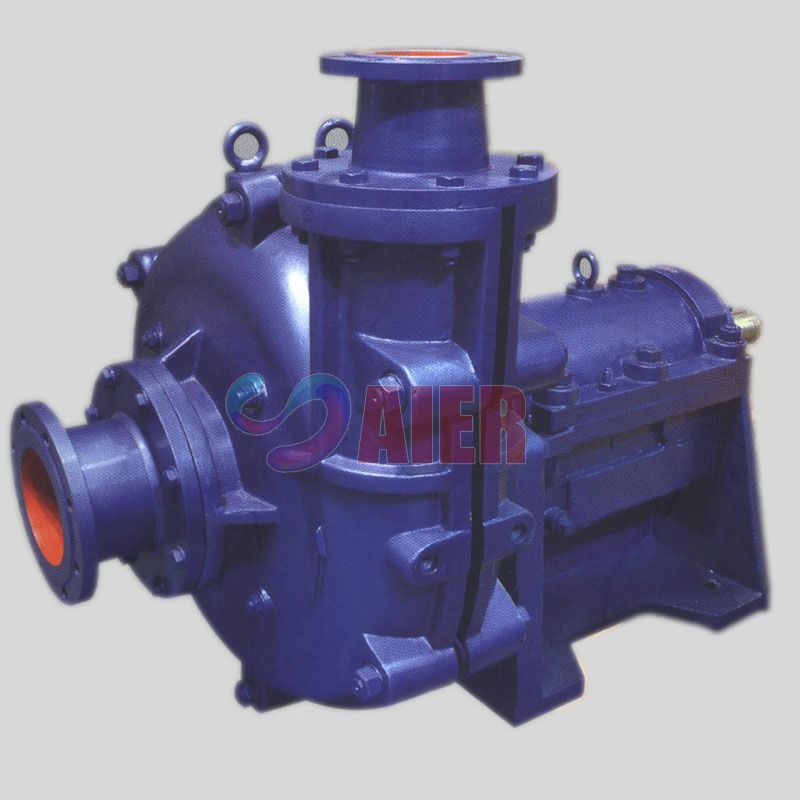

Interchangeable Spare Parts for Slurry Pumps An Overview

Slurry pumps are crucial components in various industrial applications, particularly in mining, dredging, and mineral processing. They are specifically designed to handle abrasive and corrosive materials, including slurries that consist of solids suspended in fluids. To ensure the longevity and efficiency of these pumps, the availability of high-quality interchangeable spare parts is essential. This article delves into the significance of interchangeable spare parts for slurry pumps, exploring their benefits, common types, and factors to consider when sourcing them from factories.

Importance of Interchangeable Spare Parts

The concept of interchangeable spare parts plays a pivotal role in the maintenance and repair of slurry pumps. Due to the demanding environments in which these pumps operate, wear and tear is inevitable. Components such as impellers, liners, and seals can degrade over time, leading to reduced efficiency and potential breakdowns. Using interchangeable parts allows for quicker repairs and less downtime, as these parts can be easily swapped without the need for extensive modifications.

Additionally, interchangeable spare parts contribute to cost-effectiveness. Instead of relying on original equipment manufacturer (OEM) parts, which can be significantly more expensive, operators can opt for high-quality substitutes from reputable factories. This choice reduces operational costs while maintaining the pump’s performance standards.

Common Types of Interchangeable Spare Parts

1. Impellers As the core component of a slurry pump, impellers must be durable enough to handle abrasive materials. Interchangeable impellers are designed to fit various pump models, ensuring compatibility and efficiency in performance.

2. Linings The lining of a slurry pump protects its casing from wear caused by the slurry fluid. There are several materials, such as rubber and metal, that can be utilized interchangeably based on specific application needs, enhancing resistance to corrosion and abrasion.

3. Seals Seals prevent leaks and protect against environmental contamination. Interchangeable seals can be sourced from various manufacturers, providing options that meet the performance requirements of different pump types.

4. Bearings Bearings support the rotating shaft of the pump and make it easier for the pump to operate smoothly. Interchangeable bearings are widely available and can significantly reduce maintenance costs.

slurry pump interchangeable spare parts factory

5. Suction and Discharge Hoses These hoses are essential for the effective operation of slurry pumps. Interchangeable hoses that match the pump specifications are readily available, ensuring optimal flow rates and minimal resistance.

Sourcing Interchangeable Spare Parts from Factories

When looking for interchangeable spare parts, it is vital to choose a reputable factory that specializes in manufacturing high-quality components. Here are some factors to consider

- Quality Assurance Ensure that the factory adheres to strict quality control measures, such as ISO certifications. This guarantees that the parts meet industry standards and are reliable for use in slurry pumps.

- Compatibility Verify that the parts are designed to be interchangeable with the specific make and model of your slurry pump. Detailed specifications and compatibility charts can assist in making informed choices.

- Material Selection The materials used in spare parts significantly affect their durability and performance. Factories that offer a variety of materials provide flexibility in choosing the best options for specific applications.

- Lead Time and Availability Timely delivery is crucial to minimize downtime. Select a factory known for efficient production schedules and availability of parts.

- Warranty and Support Look for suppliers that offer warranties on their products and provide excellent customer support. This ensures that you receive assistance if any issues arise after purchase.

Conclusion

Interchangeable spare parts for slurry pumps are vital for maintaining the operational efficiency and longevity of these essential industrial tools. By sourcing high-quality components from reliable factories, operators can mitigate downtime, reduce costs, and enhance the overall performance of their slurry pumps. As industries continue to evolve, the importance of reliable and interchangeable spare parts will only grow, making it imperative for businesses to invest in quality solutions for their slurry pump needs.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025