Sep . 30, 2024 23:56 Back to list

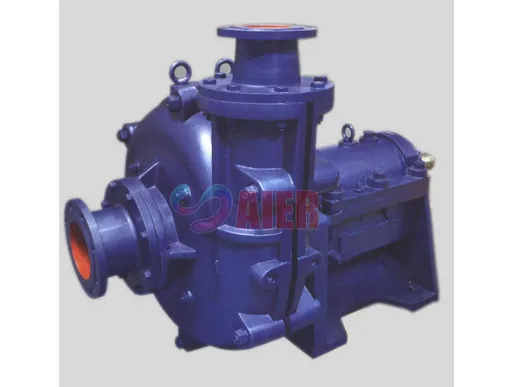

China Slurry Pump Liners and Parts for Enhanced Performance and Durability

Understanding China Slurry Pump Parts The Importance of Liners

In the world of industrial pumps, slurry pumps play a crucial role, especially in sectors like mining, construction, and wastewater management. Among the various components that contribute to the efficiency and longevity of a slurry pump, the liner stands out as a vital part. This article delves into the significance of slurry pump liners, particularly focusing on those manufactured in China.

What Are Slurry Pump Liners?

Slurry pump liners are protective barriers that are installed within the pump casing. They are designed to minimize wear and tear on the pump components while handling abrasive slurries. Due to the corrosive and abrasive nature of materials such as sand, clay, and other particulates, the liners must be robust and durable to ensure the optimal functioning of the pump over extended periods.

Materials Used for Liners

China's manufacturing sector has developed a variety of materials used for slurry pump liners, each offering distinct advantages. Common materials include

1. Rubber Rubber liners are popular for their flexibility and resistance to corrosion. They can absorb shock and are particularly effective in applications where the slurry contains less abrasive particles.

2. Metal Alloys Hard metal liners made from high-chromium alloys are employed in environments where slurries are highly abrasive. These liners offer superior wear resistance and are essential for heavy-duty applications.

3. Composite Materials Advances in materials science have led to the development of composite liners that combine the benefits of rubber and metal. These liners are designed to provide increased wear resistance while maintaining a degree of flexibility.

Importance of Quality Liners

The quality of slurry pump liners significantly influences the overall performance and maintenance costs of the pump system. Here are several reasons why investing in high-quality liners from reputable manufacturers, like those in China, is essential

china slurry pump parts liner

1. Extended Service Life High-quality liners are engineered to withstand severe conditions, substantially extending the service life of the pump. This reduction in wear not only lowers replacement costs but also minimizes downtime, ensuring continuous operation.

2. Improved Efficiency Well-designed liners contribute to the overall efficiency of the slurry pump. They reduce turbulence and maintain the flow rate, leading to better energy consumption and operational costs.

3. Compatibility Quality liners are designed to fit seamlessly with various slurry pump models. This compatibility is crucial for ease of installation and maintenance. Manufacturers in China often offer a wide range of customizable options to meet specific operational needs.

4. Cost-Effectiveness Although high-quality liners may involve a higher initial investment, the long-term benefits outweigh costs. Reduced maintenance, fewer breakdowns, and lower energy consumption contribute to significant savings over time.

Choosing the Right Liner

Selecting the appropriate slurry pump liner involves several considerations

- Type of Slurry Understanding the composition of the slurry, including its abrasiveness and corrosiveness, is critical. This will help in selecting the right material for the liner.

- Operating Conditions Factors such as temperature, pressure, and flow rates influence the performance of the pump and liner. Buyers should evaluate these conditions before making a selection.

- Manufacturer Reputation Choosing a reputable manufacturer is essential. Companies in China, known for their rigorous quality control and advanced manufacturing processes, can provide reliable liners that meet international standards.

Conclusion

Liners are a pivotal component of slurry pumps, and the choices made regarding them can have far-reaching implications for operational efficiency and cost-effectiveness. With China's advanced manufacturing capabilities and a commitment to quality, its slurry pump parts, particularly liners, are a critical asset for industries dealing with challenging materials. Investing in high-quality liners not only enhances pump performance but also contributes to sustained operational success in the industrial landscape. As such, companies must prioritize quality and reliability when selecting slurry pump liners to ensure the longevity and efficiency of their pumping systems.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025