dec . 20, 2024 06:07 Back to list

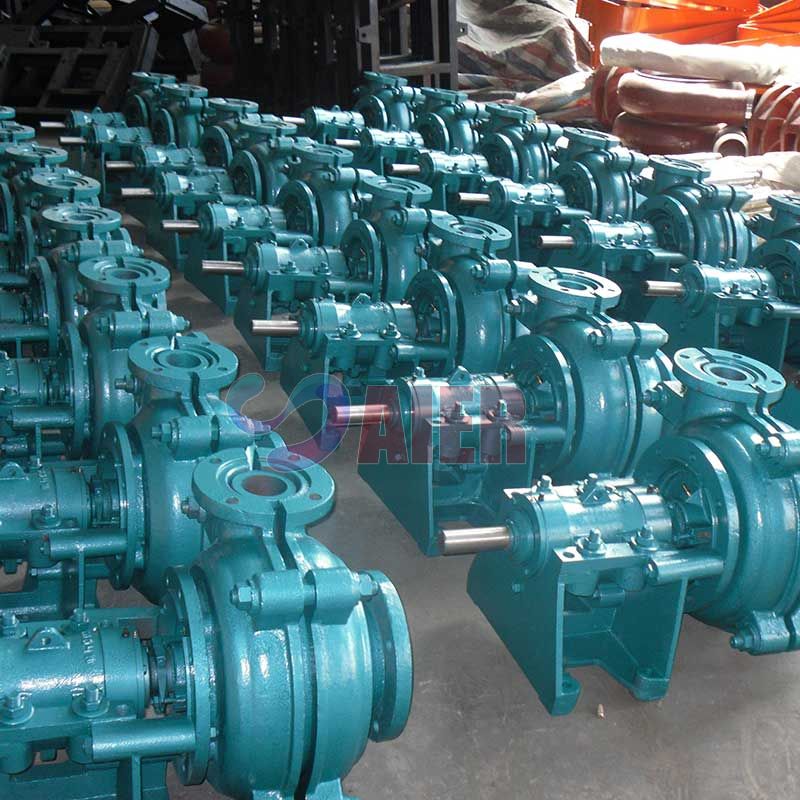

vertical centrifugal slurry pump

Vertical Centrifugal Slurry Pumps Essential Tools for Tough Applications

In various industrial applications, particularly in mining, dredging, and water treatment, the demand for efficient and reliable pumping solutions is paramount. Among the most effective options available on the market today are vertical centrifugal slurry pumps. These specialized pumps have been designed to handle abrasive, viscous, and corrosive materials, making them essential in environments where traditional pumps may fail.

What is a Vertical Centrifugal Slurry Pump?

A vertical centrifugal slurry pump is a type of pump that is specifically designed to transport slurry—a mixture of solids and liquids. This pump operates on the principle of centrifugal force, utilizing a rotating impeller to impart energy to the slurry, which then flows through the impeller and diffuser into the discharge pipe. The vertical design of these pumps allows for a compact installation, maximizing operational efficiency and minimizing required floor space.

Advantages of Vertical Design

The vertical orientation of these pumps offers multiple benefits. Firstly, it minimizes the footprint required for installation. In many facilities, space is a premium, and vertical slurry pumps can comfortably fit into tight areas without compromising on performance. Additionally, the vertical design aids in self-priming capabilities; these pumps can be installed above the slurry source, and they efficiently draw the liquid upward, which is crucial in applications where the slurry source may vary in elevation.

Key Features and Materials

Vertical centrifugal slurry pumps come equipped with robust features that enhance their performance and longevity. For instance, they often incorporate wear-resistant materials such as rubber, polyurethane, or hardened chrome iron. These materials help mitigate the effects of abrasive particles found in slurries, resulting in extended service life and reduced maintenance costs.

Moreover, these pumps are typically fitted with heavy-duty bearings and seals to withstand the rigors of heavy-duty applications. Customizable impeller designs allow for adjustments in specific situations, improving efficiency depending on the slurry characteristics.

vertical centrifugal slurry pump

Applications in Various Industries

The versatility of vertical centrifugal slurry pumps makes them suitable for a wide array of industries. In mining operations, they are frequently used for transporting tailings and slurries created during ore processing. Similarly, in construction and dredging, these pumps facilitate the movement of sand, gravel, and sludge, ensuring that work sites remain efficient and operational.

Moreover, in wastewater management, vertical slurry pumps play a critical role in the treatment process. They can handle both raw sewage and treated effluent, helping to maintain the required flow rates of modern treatment facilities. The ability to operate over varying load conditions makes them valuable assets in these settings.

Maintenance and Considerations

While vertical centrifugal slurry pumps are built to endure harsh conditions, regular maintenance is crucial to ensure optimal performance. Operators must routinely check for blockages, wear in the impellers, and the condition of seals and bearings. Establishing a preventative maintenance schedule can significantly reduce the risk of unexpected failures and extend the pump's operational lifespan.

When selecting a vertical centrifugal slurry pump, one must consider factors such as the specific type of slurry being handled, the required flow rate, and the system head. Consulting with manufacturers or industry experts can provide essential insights into the best pump configurations for particular applications.

Conclusion

Vertical centrifugal slurry pumps are indispensable tools in sectors dealing with challenging materials. Their robust construction, efficient operation, and adaptability to various environments make them a preferred choice for many industries. As the demand for efficient slurry management continues to grow, these pumps are set to remain at the forefront of industrial pumping solutions, ensuring processes run smoothly and efficiently.

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025