dec . 04, 2024 14:54 Back to list

China Manufacturer of Slurry Pump Impellers Using High-Quality Materials for Durability

Understanding Slurry Pump Impeller Materials A Focus on Chinese Manufacturers

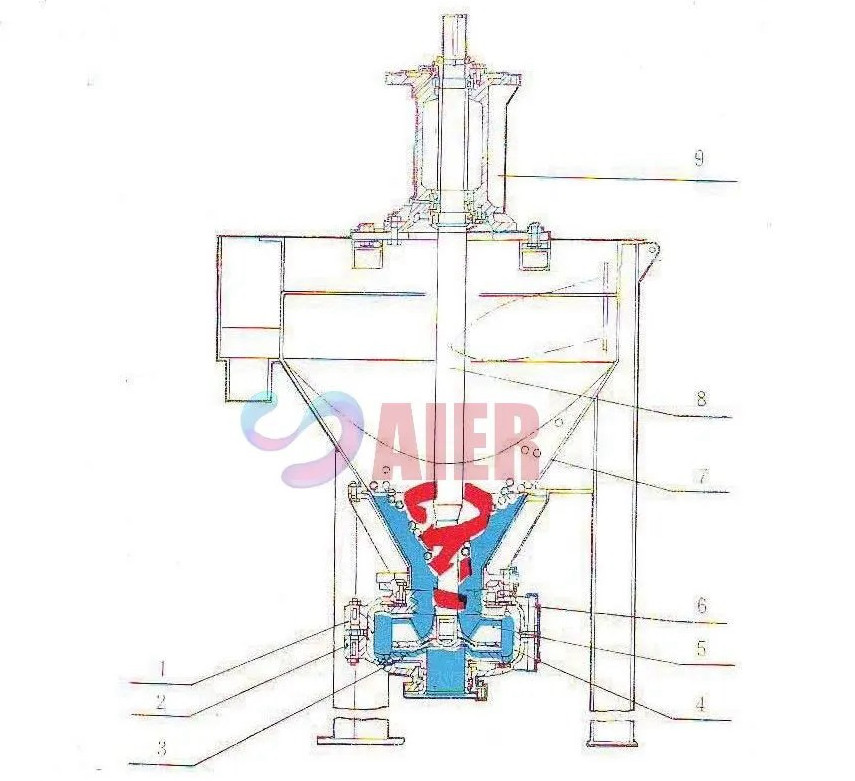

In the world of industrial machinery, slurry pumps play a crucial role in transporting abrasive and viscous fluids, often in mining, mineral processing, and wastewater treatment applications. The efficiency and durability of a slurry pump are significantly influenced by its impeller—one of its most critical components. In recent years, China has emerged as a leading manufacturer of slurry pump impellers, offering a range of materials that cater to diverse operational conditions.

The Importance of Impeller Materials

The impeller of a slurry pump is responsible for converting rotational energy into kinetic energy, enabling the fluid to move through the pump system. Given the abrasive nature of the fluids involved, the choice of material for impellers is crucial. The right material not only enhances the pump's efficiency but also extends its service life, minimizing downtime and maintenance costs.

Common Impeller Materials

1. Cast Iron This is one of the most commonly used materials for slurry pump impellers due to its good wear resistance and mechanical properties. Cast iron is relatively cost-effective and is often treated with coatings to enhance its performance in abrasive environments.

2. High Chromium Alloy Known for its superior hardness, high chromium alloy is ideal for applications involving highly abrasive slurries. Manufacturers in China often offer impellers made from this material, which can withstand extensive wear and tear over time.

3. Rubber For applications requiring resistance to corrosion and less abrasive slurries, rubber impellers are an excellent choice. Chinese manufacturers have developed advanced rubber compounds that offer flexibility and durability, making them suitable for varied operational contexts.

4. Polyurethane Increasingly popular due to its excellent wear resistance and lighter weight compared to metal options, polyurethane impellers are designed for specific applications. They are particularly effective in handling slurries with a lower density and less abrasive characteristics.

5. Stainless Steel For environments that require high corrosion resistance, stainless steel impellers are often used. While more expensive, they offer longevity and are suitable for transferring slurry that contains corrosive materials.

Advantages of Chinese Manufacturers

Chinese manufacturers have become prominent in the slurry pump industry due to several factors

china slurry pump impeller material manufacturer

- Cost-Effectiveness Manufacturers in China are able to produce high-quality impellers at competitive prices. This affordability makes it easier for industries to invest in quality equipment without straining budgets.

- Technological Advancements Many Chinese companies have adopted cutting-edge technology and manufacturing processes. This has allowed them to improve the efficiency and durability of their products, keeping pace with global standards.

- Customization Chinese manufacturers often provide tailored solutions to meet specific industrial needs. This includes customizing impeller designs and materials based on the unique requirements of different operations.

- Robust Supply Chain China's well-established supply chain for manufacturing materials often ensures timely delivery and reduced lead times, which is a key consideration for industries reliant on operational efficiency.

Choosing the Right Manufacturer

When selecting a slurry pump impeller manufacturer in China, it’s important to consider several factors

- Reputation and Experience Look for manufacturers with a proven track record in producing slurry pump components. Research customer reviews and case studies to gauge their reliability.

- Quality Certifications Ensure that the manufacturer adheres to international quality standards such as ISO 9001. This certification indicates a commitment to consistent quality management.

- Technical Support Manufacturers that offer excellent technical support can be invaluable, particularly for complex installations or when troubleshooting issues arises.

Conclusion

As the demand for efficient and durable slurry pumps continues to grow globally, the role of impeller materials becomes increasingly important. Chinese manufacturers are well-positioned to meet this demand with a variety of high-quality materials and innovative solutions. By carefully considering the material, advanced manufacturing techniques, and selecting the right manufacturer, industries can ensure optimal performance and longevity of their slurry pump systems. Investing in the right impeller can lead to significant operational improvements and cost savings in the long run.

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025