Νοέ . 15, 2024 16:49 Back to list

high quality slurry pump mechanical seal

High-Quality Slurry Pump Mechanical Seals An Essential Component for Optimized Performance

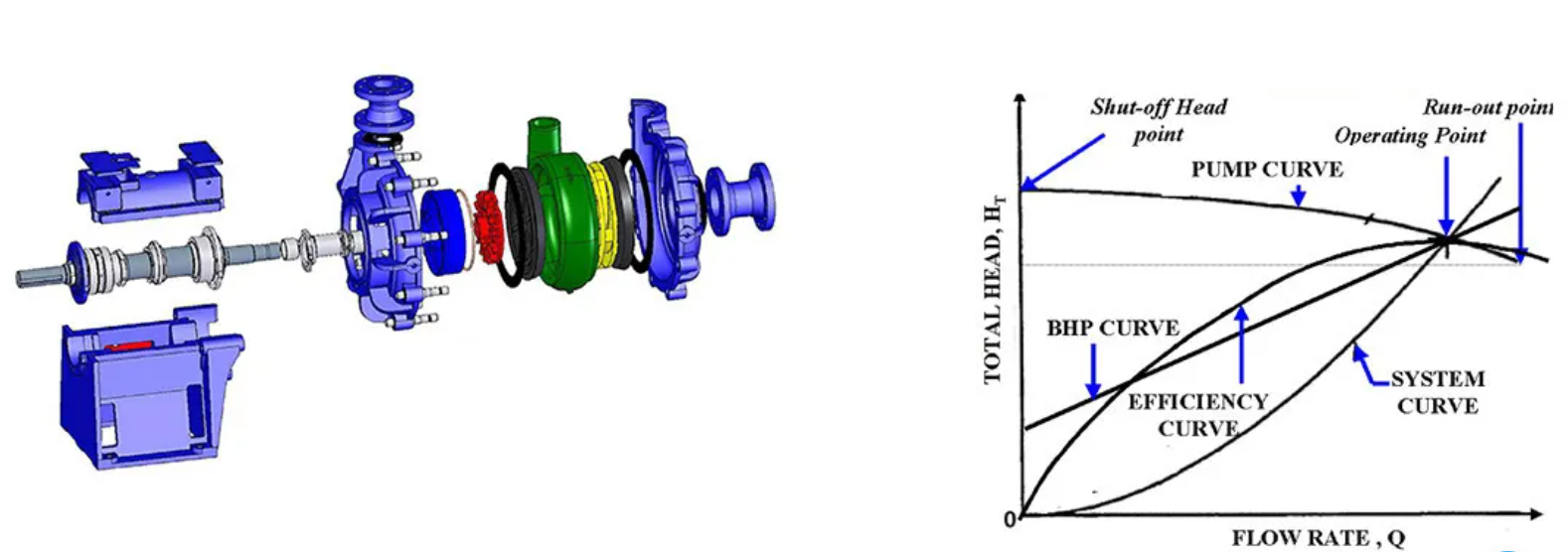

In industries that deal with the transportation of abrasive slurries—such as mining, mineral processing, and wastewater treatment—the reliability and efficiency of slurry pumps are paramount. One of the critical components that directly impact the performance of slurry pumps is the mechanical seal. High-quality slurry pump mechanical seals not only enhance the durability of the pump but also ensure operational efficiency and reduced maintenance costs.

Understanding Mechanical Seals

Mechanical seals are devices used to prevent fluid leakage in rotary equipment. They are designed to form a seal between the rotating shaft and the stationary part of the pump, thereby preventing the slurry from escaping into the environment. The design of a mechanical seal typically consists of two primary faces the rotating face, which is attached to the shaft, and the stationary face, which is fixed to the pump casing. The seal relies on a thin film of liquid to facilitate smooth interaction between these two faces in order to minimize wear.

Importance of High-Quality Mechanical Seals

1. Leak Prevention One of the main functions of a mechanical seal is to prevent leakage. A high-quality seal will effectively contain abrasive slurries, which can be chemically aggressive and physically damaging to both the pump and the environment. Uncontrolled leakage not only leads to product loss but may also pose significant environmental and safety risks.

high quality slurry pump mechanical seal

2. Operational Efficiency The integrity of mechanical seals directly impacts the operational efficiency of slurry pumps. High-quality seals reduce friction and thermal loss, resulting in lower energy consumption. This efficiency translates into reduced operational costs and increased productivity for industrial applications.

3. Longevity and Reliability In harsh environments characterized by high pressure and temperature, using premium mechanical seals is essential for longevity and reliability. High-quality materials such as tungsten carbide, ceramic, and specialized rubber compounds are often employed in seal design to withstand extreme conditions, thereby extending the lifespan of the seal and the pump.

4. Maintenance Reduction Mechanical seal failure can lead to frequent maintenance downtimes, resulting in increased operational costs. By investing in high-quality slurry pump mechanical seals, companies can significantly reduce the need for repairs and replacements, thus minimizing downtime. An effective seal enhances the overall reliability of the pump system and allows for more consistent production schedules.

5. Customization Options Different applications require different sealing loads and configurations. High-quality manufacturers often provide customizable sealing solutions that can be tailored to specific slurry characteristics, including viscosity, temperature, and chemical composition. This ensures optimal performance under varying operational conditions.

Conclusion

In conclusion, the role of high-quality slurry pump mechanical seals is crucial in maintaining the performance, safety, and efficiency of various industrial operations. Investing in top-tier seals yields substantial benefits, including leak prevention, enhanced operational efficiency, extended service life, and reduced maintenance costs. As industries continue to evolve and tackle more challenging environments, the importance of selecting and implementing high-quality mechanical seals cannot be overstated. By prioritizing these essential components, businesses can ensure the reliability and efficiency of their slurry pump systems, paving the way for sustained operational success.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025