Nov . 25, 2024 10:07 Back to list

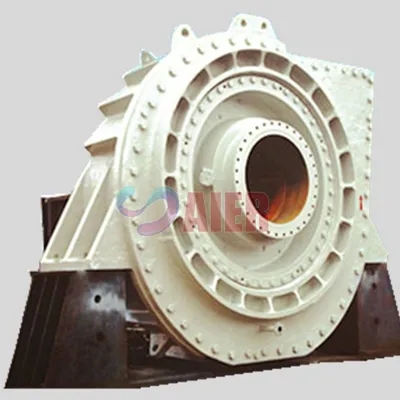

submerged slurry pump

Understanding Submerged Slurry Pumps Applications and Benefits

Submerged slurry pumps are essential industrial tools designed to handle slurry— a mixture of liquid and solid particles. These pumps are particularly popular in various sectors, including mining, construction, and wastewater management, due to their ability to transfer abrasive and corrosive materials efficiently. This article delves into the workings, applications, and advantages of submerged slurry pumps, shedding light on why they are vital in many industrial processes.

How Submerged Slurry Pumps Work

Submerged slurry pumps operate by utilizing a centrifugal mechanism. As the pump is submerged in the slurry, it draws the mixture through an inlet and imparts energy to it via an impeller. The design of the impeller and diffuser maximizes the pump's efficiency in transporting the high-density mixture. Since these pumps are often positioned below the surface of the slurry, they are engineered to resist wear and corrosion caused by the harsh particles within the slurry.

The motors that drive submerged slurry pumps are typically designed to be waterproof, ensuring they remain operational under challenging conditions. Many modern variants also feature adjustable settings that allow operators to fine-tune flow rates and pressure, enhancing versatility across various applications.

Applications of Submerged Slurry Pumps

The applications of submerged slurry pumps are wide-ranging. In the mining industry, they are crucial for transporting coal, minerals, and ores, where the mixture often includes sand, gravel, and other debris. By efficiently moving these heavy materials, submerged slurry pumps significantly improve operational efficiency and reduce downtime in mining operations.

In construction, these pumps are used to manage excavation sites. They facilitate the removal of excess water mixed with soil and rock, which is important for maintaining site stability and preparing foundations. Additionally, submerged slurry pumps play a key role in dredging operations where they assist in removing sediment from waterways, thereby helping to maintain navigable channels and prevent flooding.

submerged slurry pump

Wastewater management facilities also rely on submerged slurry pumps to handle sludge, a byproduct of the treatment process that consists of solid waste and liquid. By managing this material effectively, these pumps help ensure that wastewater treatment plants operate efficiently and adhere to environmental regulations.

Advantages of Submerged Slurry Pumps

There are several advantages to using submerged slurry pumps. First and foremost is their ability to handle abrasive materials without significant wear. The robust construction materials, often including hardened alloys and elastomers, prolong the lifespan of these pumps and enhance their reliability in demanding environments.

Additionally, submerged slurry pumps typically require less maintenance compared to surface-mounted pumps. Because they are submerged, they are less likely to experience issues such as cavitation, which can lead to operational failures. Reduced maintenance requirements lead to lower operational costs, making these pumps a cost-effective solution in the long run.

Their design also allows for easy installation and operation in difficult-to-reach areas. Many models are portable and can be easily relocated, making them ideal for temporary projects or settings where frequent movement is necessary.

Conclusion

Submerged slurry pumps are indispensable in industries that deal with heavy and abrasive materials. Their ability to efficiently transport slurries while reducing wear and maintenance enhances productivity and lowers operational costs. As industrial processes continue to evolve, the importance of reliable equipment like submerged slurry pumps cannot be overstated, making them a cornerstone of modern engineering solutions. Whether in mining, construction, or wastewater management, these pumps ensure that operations run smoothly and efficiently.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025