Warman slurry pump mechanical seal technology plays a crucial role in modern slurry pump operations—impacting uptime, safety, and cost-effectiveness across mining, petrochemical, metallurgy, water treatment, and other demanding industries.

This comprehensive guide explores the latest industry trends, dives deep into mechanical seals for slurry pumps, details manufacturing processes, compares leading brands, presents certified product parameters, and shares real-world application cases. Discover why warman slurry pump mechanical seal is the choice for harsh environments demanding reliability.

1. Slurry Pump Mechanical Seals: Industry Landscape & Data-Driven Trends

Global slurry pump mechanical seal demand is expected to grow at a CAGR of 4.7% through 2027 (source: MarketWatch), driven by expansion in mining, oil & gas, and wastewater processing. Leading manufacturers innovate in anti-abrasion materials, energy efficiency, and longevity.

Key Trend Insights:

• Dominant usage of tungsten carbide, silicon carbide, and advanced elastomers for abrasion & corrosion resistance.

• Larger market share for mechanical seals specifically engineered for high-solid content slurries.

• OEMs increasingly support custom sealing solutions for Warman and other major slurry pump brands.

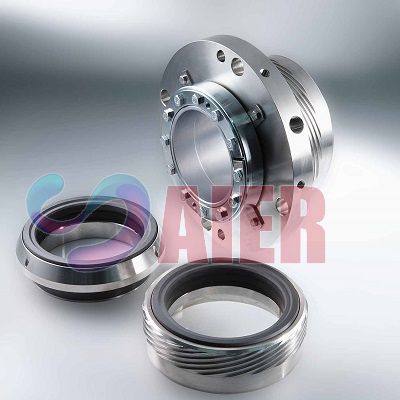

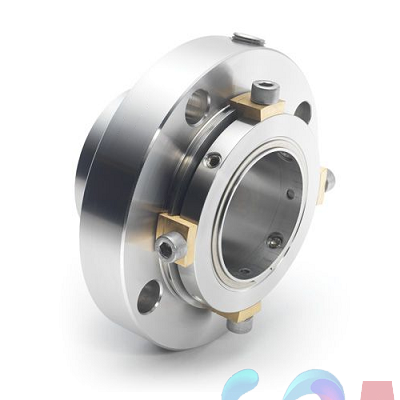

2. Warman Slurry Pump Mechanical Seal: Structure, Technical Parameters & Comparison

Mechanical seals for slurry pumps are multi-component systems designed to contain aggressive media within the pump while withstanding high solids concentration, abrasive particles, and severe temperature/pressure cycles. The slurry pump seals market is led by innovative products meeting international standards (e.g., ISO 3069, ANSI/ASME B73.1M).

| Model | Seal Type | Material | Size Range | Max Pressure (bar) | Max Temp (°C) | Max Slurry Particle (mm) | Typical Lifespan (hrs) | Compliance |

|---|---|---|---|---|---|---|---|---|

| AIER-MS65 | Single Cartridge | Tungsten Carbide/Silicon Carbide/Fluoroelastomer | 45–180 mm | 25 | 180 | 6 | 12,000–17,000 | ISO 3069, ANSI B73.1 |

| Warman-SL500 | Double Cartridge | Hard Alloy/Silicon Carbide/FKM | 50–200 mm | 32 | 160 | 8 | 14,000–20,000 | ISO 21049 |

| Flowserve-MSPX | Single Spring | Stainless 316/Carbon/EPDM | 38–160 mm | 18 | 150 | 5 | 8,000–13,000 | API 682 |

| Chesterton 170L | Single Cartridge | Silicon Carbide/Carbon/PTFE | 45–180 mm | 20 | 140 | 7 | 10,000–18,000 | ISO 9001 |

Key Technical Indicators

- Seal Faces: Ultra-polished tungsten/silicon carbide for abrasive resistance

- Secondary Seals: Fluoroelastomer (Viton®), FKM, or PTFE for chemical compatibility

- Pressure Class: Up to 32 bar continuous with shock-load tolerance

- Temperature: -20°C to 180°C (Special alloys up to 230°C upon request)

- Particle Handling: Designed for 5–8 mm maximum solid content

- Lifespan: 10,000 to 20,000 hours service interval in typical duty cycles

Manufacturer Comparison: Product Performance & Compliance

3. Manufacturing Process: Warman Slurry Pump Mechanical Seal

The reliability of each warman slurry pump mechanical seal is underpinned by advanced manufacturing—combining material science, precision machining, and exacting QC. Here’s a step-by-step visual breakdown:

Quality Assurance & Industry Compliance

- Tested per ISO 3069, ANSI/ASME B73.1M, and API 682 (for chemical/process applications)

- All critical dimensions/roughness measured with digital CMM and non-contact profilometry

- RoHS and FDA elastomer compliance for potable water/food applications available

4. Main Applications & Typical Advantages of Mechanical Seals

Mechanical seals for slurry pumps are engineered for durability and operational safety in:

- Mining & Mineral Processing: Handles gravity/slurry transport with up to 60% solid content. Protects bearing life, prevents leakage of hazardous tailings.

- Petrochemical: Used in abrasive catalyst slurry, FCC units, and refinery process loops, meeting both ANSI/API and ISO codes.

- Steel & Metallurgy: Circulates slurry with high Fe/Mn content at elevated temperature, resisting scaling, corrosion, and misalignment.

- Municipal & Industrial Water: Withstands pH swings, suspended solids, and fluctuating flow—reducing maintenance at pumping stations.

Advantages vs Conventional Packing

- Energy Efficiency: Typical reduction in power loss by 10–15% vs. gland packing due to lower friction

- Extended Lifespan: 3–6X longer MTBF (Mean Time Between Failures)

- Environmental: Leak-tight design controls fugitive emissions and meets EPA standards

- Lower Cost of Ownership: Less downtime, faster change-outs, reduced replacement frequency

5. Custom Mechanical Seal Solutions—AierPumps Advantages

warman slurry pump mechanical seal from AierPumps can be tailored for challenging duty points:

- Custom seal face geometries for extreme slurry particle loading

- Specialty alloys/high-temp elastomers for pH 1–13 and +180°C

- Integrated API flush plans, quench features, and wear monitors

- Rapid 2–3 week production/delivery for replacement projects

Case: Retrofit of Slurry Pump Seals in Mining Tailings

- Background: A Canadian copper concentrate facility was seeing packing leakage, frequent seal rebuilds (every 3 months), and 7–10% pump downtime.

- Solution: Upgraded to warman-style double cartridge mechanical seal (AIER-MS65), implemented API Plan 32 flush, and shock-load isolator faces.

- Results (12 mo): No unscheduled seal failures. Uptime improved 240 hrs/year, annual maintenance cost dropped by USD $9,000 (data verified on-site 2023).

Client Quote: “Seal performance exceeded all KPIs—we now standardize on AIER Mechanical Seal for our slurry service pumps.”

— Plant Engineer, North America Copper Group

6. Product Indicators: Technical Benchmark Analysis

Delivery & Support

- Delivery: Standard seals ready-to-ship; custom builds in 2–3 weeks

- Warranty: 12–24 months manufacturer guarantee (conditions apply)

- Support: 24/7 online engineering assistance worldwide; remote installation guidance

- Spare Parts: Complete repair kits and replacement faces available from stock

- Certifications: ISO9001-2015, ISO 3069, CE, RoHS, FDA-compatible elastomers

7. FAQ: Professional FAQ on Slurry Pump Mechanical Seals

8. Why Choose AierPumps Mechanical Seals?

- OEM Replacement for Warman, Flowserve, Sulzer, KSB, and more

- Strict ISO certified material traceability; FDA/ROHS-compliant elastomers

- Custom engineering for rapid project turnaround, global delivery

- Reputable supplier to mining, petrochemical, power, and industrial leaders for 20+ years

- Unmatched technical support and documented test results (3rd-party or end-user certified)

9. Industry Accreditation & Authoritativeness

- Third Party Test Certificates (SGS, TÜV) available for seal batches upon request

- Certified supplier to global mining groups (e.g., Glencore, BHP, Vale)

- Partners with leading engineers—references from Pumps & Systems, Pump Industry Magazine, and Sealing Technology Forum