Yan . 14, 2025 12:32 Back to list

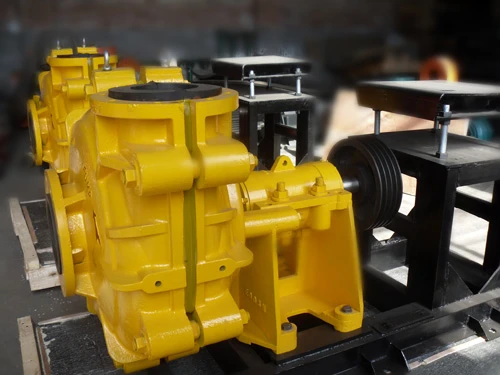

horizontal froth slurry pump

Choosing the right horizontal froth slurry pump is crucial for industrial applications that involve transporting frothy fluids or slurries containing air or other entrained gases. These pumps are distinguished by their ability to effectively handle the disruptive characteristics of froth and maintain stable performance. With years of experience in the field of industrial pumping solutions, I can assure you that selecting a pump that meets specific needs not only optimizes your processes but also enhances operational reliability.

Trust in a horizontal froth slurry pump also stems from the assurances provided by comprehensive service and support networks. Reputable manufacturers offer extensive training and technical support, often providing on-site assessments to tailor the pumping systems to your specific applications. These services are invaluable for troubleshooting and maintaining peak performance, reinforcing the trustworthiness of both the pump and the company behind it. Moreover, the emphasis on sustainability and energy efficiency in modern industrial sectors is reflected in the design of these pumps. Advanced models are designed to minimize energy consumption while maximizing output, aligning with global sustainability goals. By reducing energy usage, operators can significantly lower operational costs, thus contributing to a more sustainable and cost-effective industrial process. In conclusion, when considering a horizontal froth slurry pump, it is imperative to evaluate the experience and expertise behind the product, assess the authoritative design and manufacturing standards, and ensure trustworthy support systems are in place. These factors collectively optimize performance and reliability, ultimately driving success across a range of demanding industrial applications. Whether you are dealing with mineral processing, wastewater management, or chemical manufacturing, a well-selected horizontal froth slurry pump can be a pivotal component of your operational strategy.

Trust in a horizontal froth slurry pump also stems from the assurances provided by comprehensive service and support networks. Reputable manufacturers offer extensive training and technical support, often providing on-site assessments to tailor the pumping systems to your specific applications. These services are invaluable for troubleshooting and maintaining peak performance, reinforcing the trustworthiness of both the pump and the company behind it. Moreover, the emphasis on sustainability and energy efficiency in modern industrial sectors is reflected in the design of these pumps. Advanced models are designed to minimize energy consumption while maximizing output, aligning with global sustainability goals. By reducing energy usage, operators can significantly lower operational costs, thus contributing to a more sustainable and cost-effective industrial process. In conclusion, when considering a horizontal froth slurry pump, it is imperative to evaluate the experience and expertise behind the product, assess the authoritative design and manufacturing standards, and ensure trustworthy support systems are in place. These factors collectively optimize performance and reliability, ultimately driving success across a range of demanding industrial applications. Whether you are dealing with mineral processing, wastewater management, or chemical manufacturing, a well-selected horizontal froth slurry pump can be a pivotal component of your operational strategy.

Latest news

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Industrial Mining Equipment

NewsAug.02,2025